Assembly-type wallboard manufacturing device

A production device and assembly technology, applied in the direction of manufacturing tools, ceramic molding machines, ceramic molding cores, etc., can solve the problems of easy bulging and cracking of the coating, affecting the appearance, and limited wallboard structure, so as to improve the waterproof effect, Conducive to renovation and maintenance, improve the effect of installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

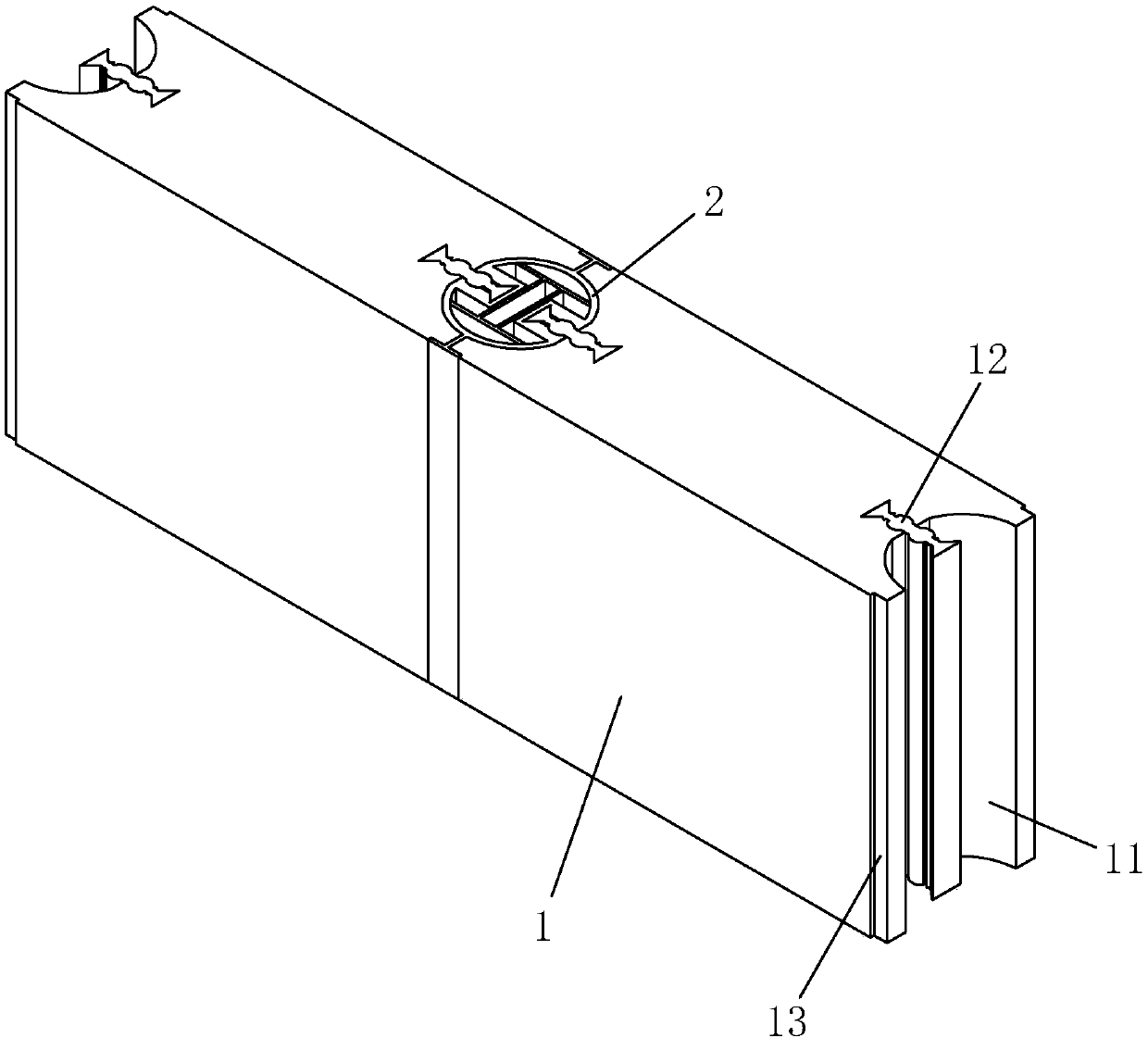

[0042] Embodiment one: a kind of assembled wallboard, such as figure 1 As shown, it includes a plate body 1 and a pipe body 2 connected between two adjacent plate bodies 1 .

[0043] refer to figure 1 , the board body 1 can be made of foamed cement, and the size specification is 2500mm×600mm×150mm. According to the needs, the board body 1 can also be designed into other sizes. Both sides of the plate body 1 are provided with a semicircular groove 11 matching the outer contour of the pipe body 2 along its length direction, and the side of the plate body 1 close to the groove 11 is fixed with a waterproof plate 12 along the midline of the plate body thickness. On both sides of the groove 11, there are clamping strips 13 formed.

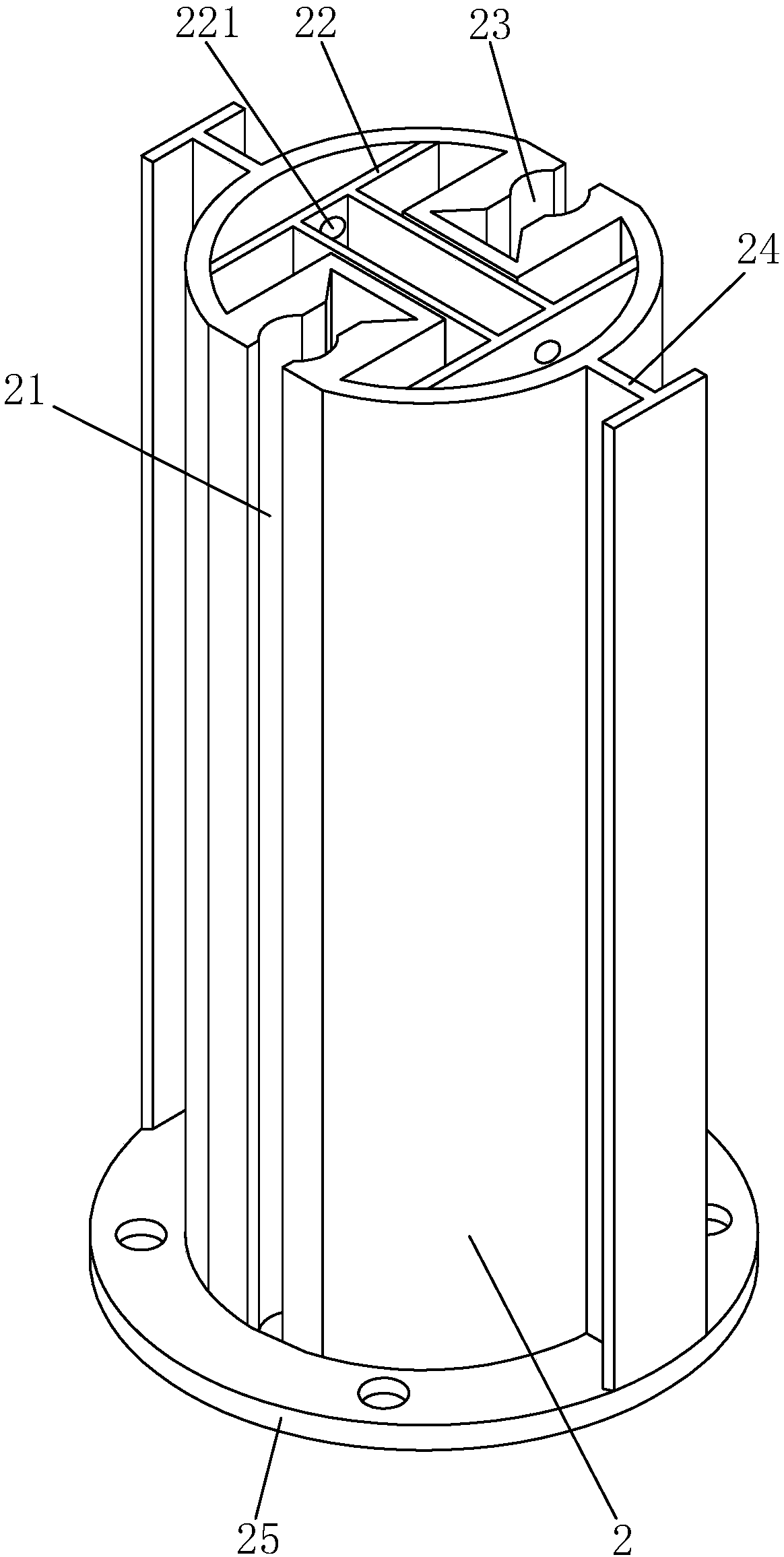

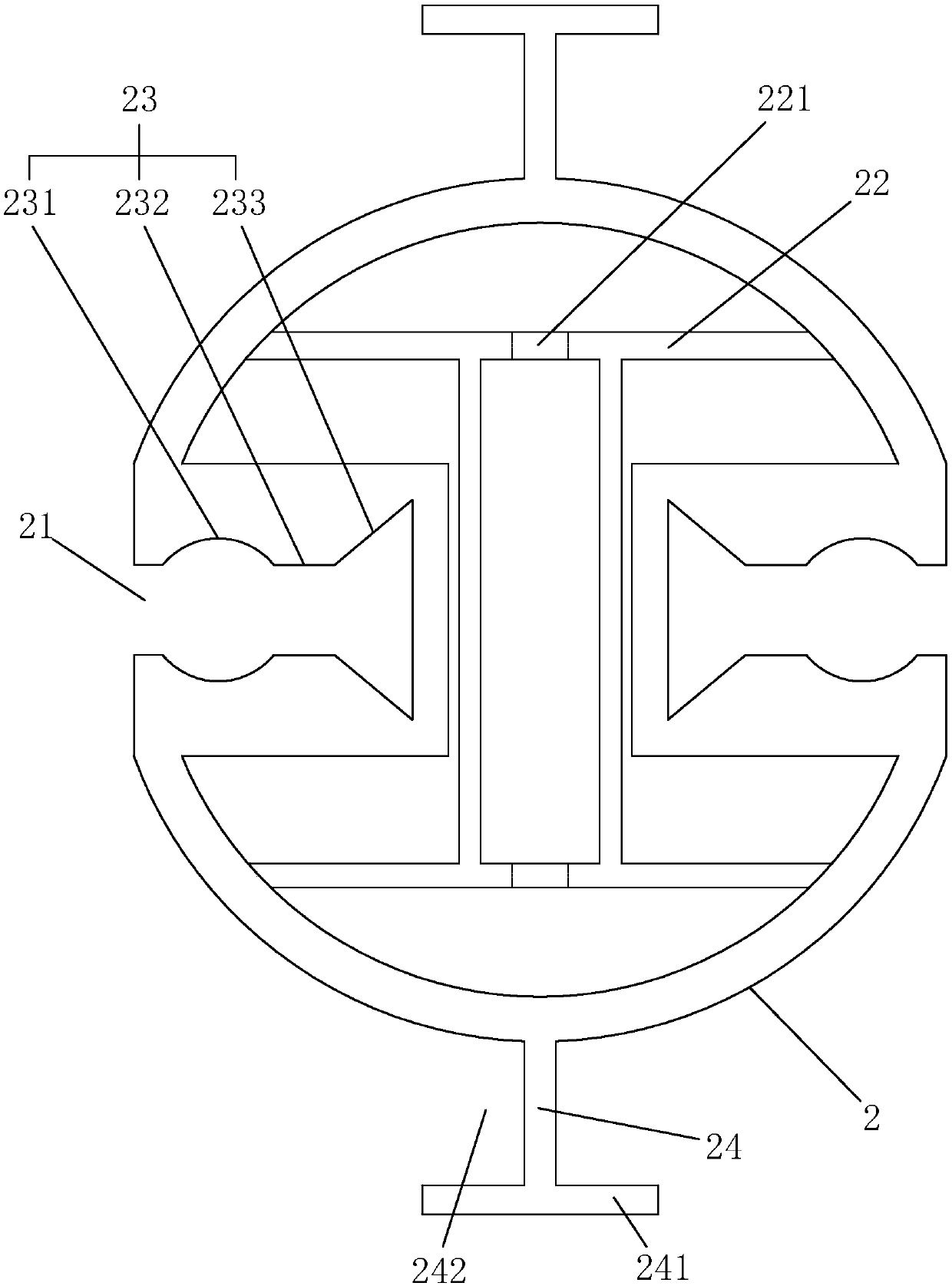

[0044] refer to figure 2 and image 3 , the pipe body 2 is a cylindrical steel pipe, and two openings 21 are arranged on the pipe wall of the pipe body 2 along its generatrix, and the openings 21 divide the pipe body 2 into two identical parts. Th...

Embodiment 2

[0053] Embodiment two: a kind of mold that is used to make assembly-type wallboard manufacturing device, such as Image 6 and Figure 7 As shown, the mold 3 includes a front mold 31, a rear mold 32 and a base plate 33. The front mold 31 and the rear mold 32 are split and surround the base plate 33 in a cuboid structure. The joints of the front mold 31 and the rear mold 32 pass The fastener 34 is fixed, and the fastener 34 may be an existing buckle structure. Four positioning platforms 331 are arranged on the bottom plate 31 , and the positioning platforms 331 are engaged with the support plate 22 inside the tube body 2 to be fixed, so that the tube body 2 is fixed on the bottom plate 31 . The number of positioning platforms 331 is determined according to the specifications of the fabricated wallboard manufacturing device, so that a corresponding number of pipe bodies 2 are fixed in the mold 3 . The pipe body 2 is different from the pipe body 2 in the first embodiment in that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com