Method for preventing silicon content from increasing during smelting of ultra-low-carbon and ultra-low-silicon steel

A smelting process, ultra-low carbon technology, applied in the manufacture of converters and other directions, can solve problems such as insufficiency, and achieve the effect of solving the problem of silicon addition, reducing the rate of change of judgment, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

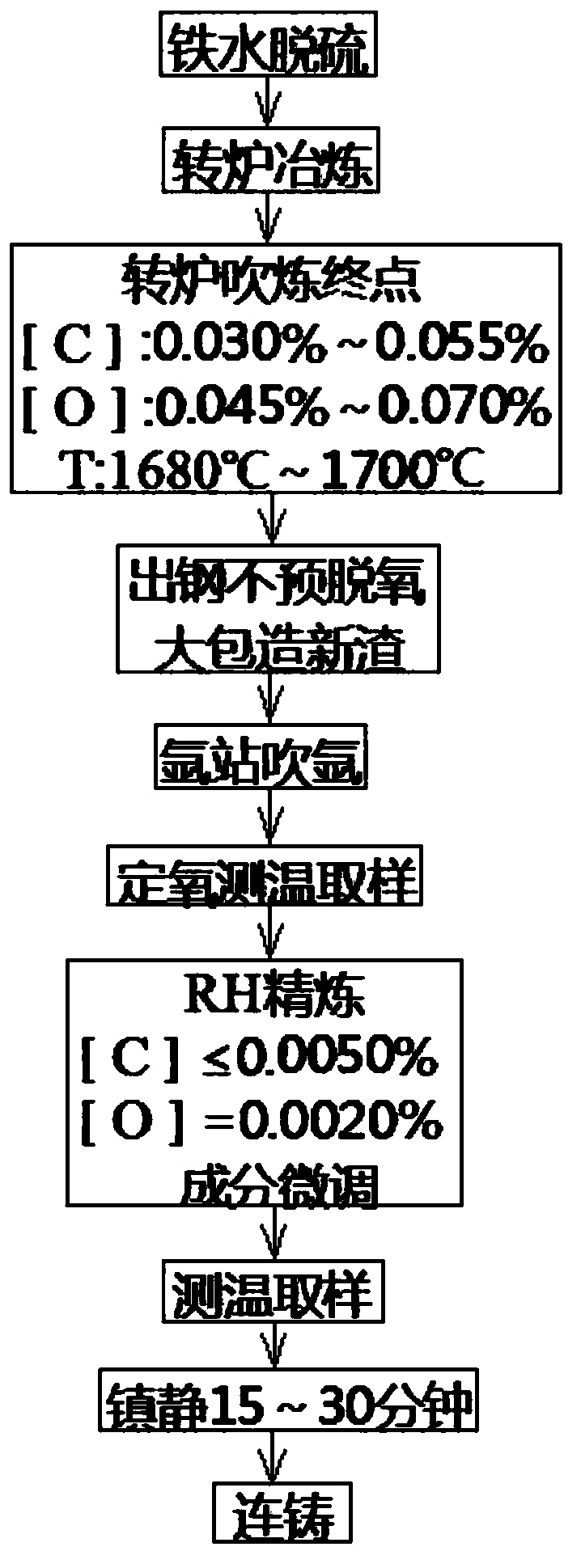

Method used

Image

Examples

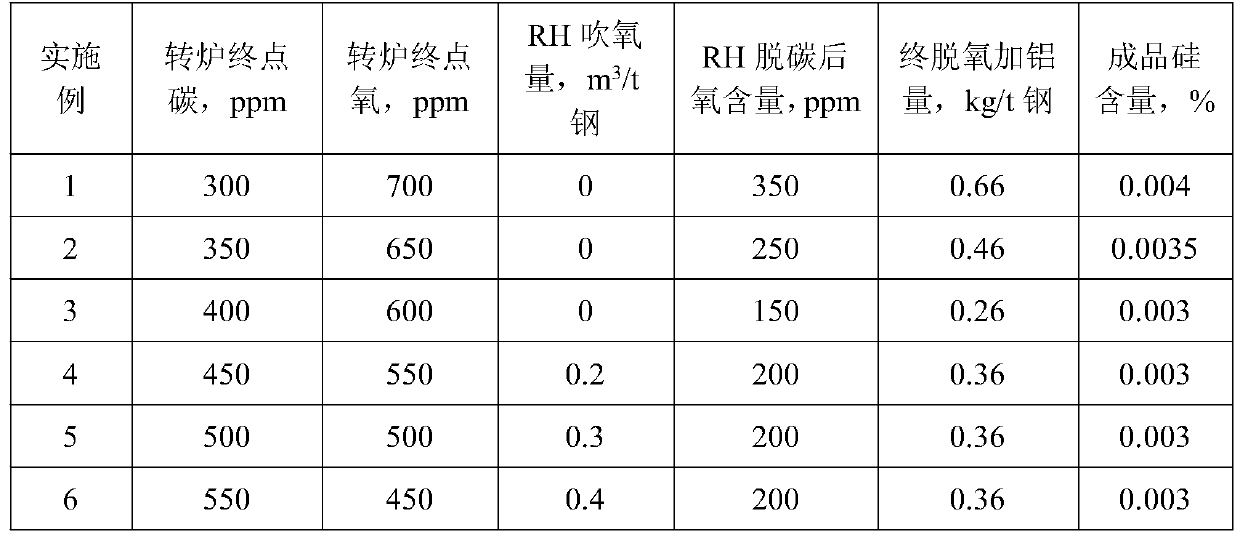

Embodiment 1

[0034]Desulfurization of molten iron: molten iron: S=0.002%, Ti+Nb+V=0.020%, strictly control residual elements Cu+Ni+Cr+Mo≤0.05% in steel.

[0035] Converter smelting: endpoint carbon 0.030%, O=0.070%. Tapping temperature: 1700°C; tapping without pre-deoxidation.

[0036] RH refining: Natural decarburization is adopted in RH, and the pressure in the furnace is kept below 100Pa. After the carbon is removed to 0.005%, the free oxygen in the steel is 350ppm. Add aluminum pellets for deoxidation, the free oxygen in the steel is 20ppm, and the aluminum content in the steel is 0.005%. And deoxidize the slag surface, the total iron + manganese oxide in the slag is 10%. Molten steel was quenched for 15 minutes and then continuously cast.

[0037] Continuous casting: the tundish is blown and baked for more than 3 hours, and the tundish is replaced with argon before continuous casting. The ladle nozzle is sealed with argon, and the tundish adopts an immersion nozzle to reduce the c...

Embodiment 2

[0039] Desulfurization of molten iron: molten iron: S=0.0018%, Ti+Nb+V=0.018%, strictly control residual elements Cu+Ni+Cr+Mo≤0.05% in steel.

[0040] Converter smelting: endpoint carbon 0.035%, O=0.065%. Tapping temperature: 1697°C; tapping without pre-deoxidation.

[0041] RH refining: Natural decarburization is adopted in RH, and the pressure in the furnace is kept below 100Pa. After the carbon is removed to 0.0048%, the free oxygen in the steel is 250ppm. Add aluminum pellets for deoxidation, the free oxygen in the steel is 18ppm, and the aluminum content in the steel is 0.0048%. And deoxidize the slag surface, the total iron + manganese oxide in the slag is 9%. Molten steel was quenched for 15 minutes and then continuously cast.

[0042] Continuous casting: the tundish is blown and baked for more than 3 hours, and the tundish is replaced with argon before continuous casting. The ladle nozzle is sealed with argon, and the tundish adopts an immersion nozzle to reduce th...

Embodiment 3

[0044] Desulfurization of molten iron: molten iron: S=0.0015%, Ti+Nb+V=0.015%, strictly control residual elements Cu+Ni+Cr+Mo≤0.05% in steel.

[0045] Converter smelting: endpoint carbon 0.040%, O=0.060%. Tapping temperature: 1694°C; tapping without pre-deoxidation.

[0046] RH refining: Natural decarburization is adopted in RH, and the pressure in the furnace is kept below 100Pa. After the carbon is removed to 0.0045%, the free oxygen in the steel is 150ppm. Add aluminum pellets for deoxidation, the free oxygen in the steel is 15ppm, and the aluminum content in the steel is 0.0045%. And deoxidize the slag surface, the total iron + manganese oxide in the slag is 8%. Molten steel was quenched for 15 minutes and then continuously cast.

[0047] Continuous casting: the tundish is blown and baked for more than 3 hours, and the tundish is replaced with argon before continuous casting. The ladle nozzle is sealed with argon, and the tundish adopts an immersion nozzle to reduce th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com