Knitwear processing and thread feeding device

A wire feeding device and knitwear technology, applied in knitting, warp knitting, textiles and papermaking, etc., can solve problems such as difficulty in meeting different wire feeding needs and difficulty in adjusting the tightness of wire feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

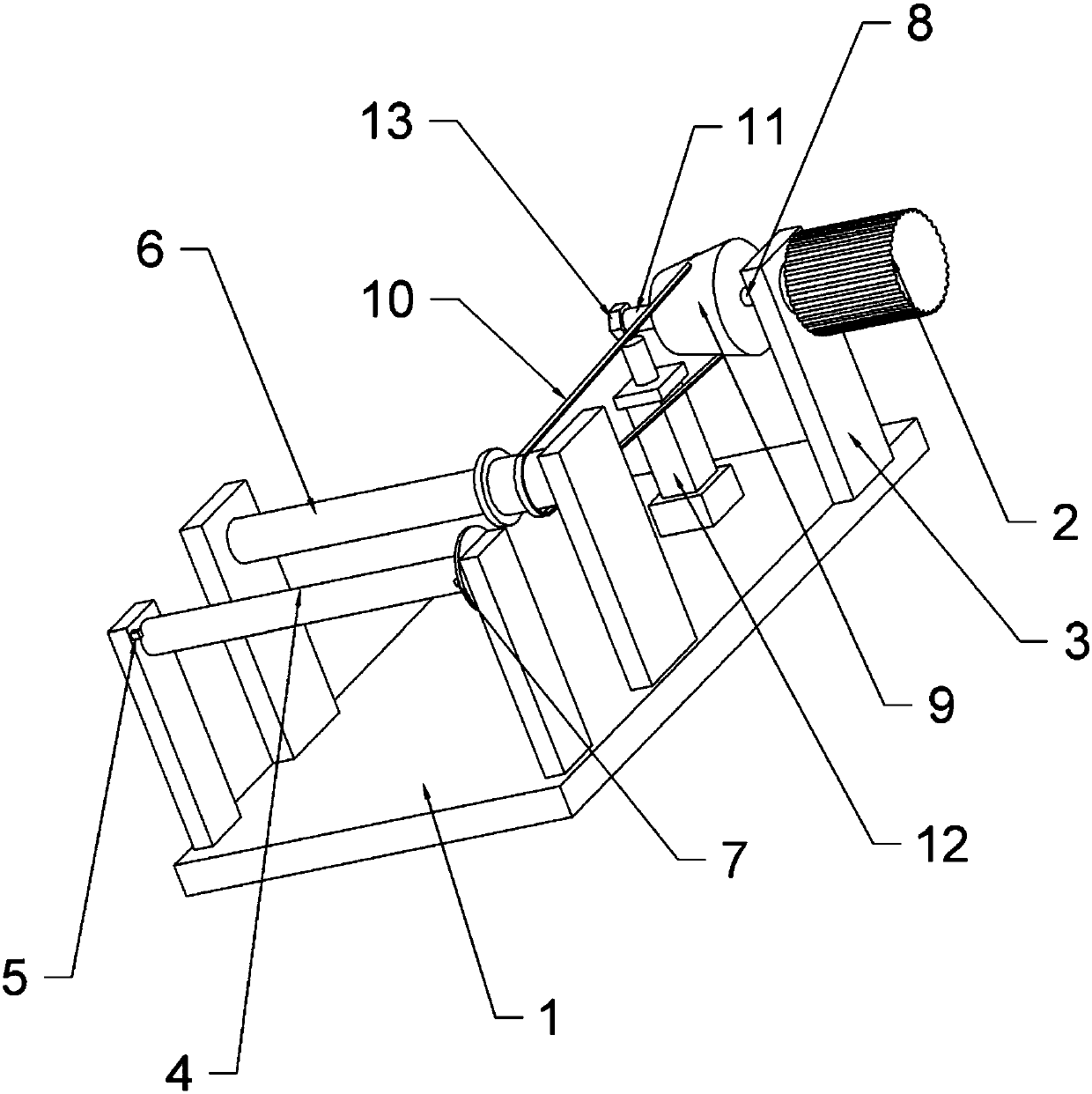

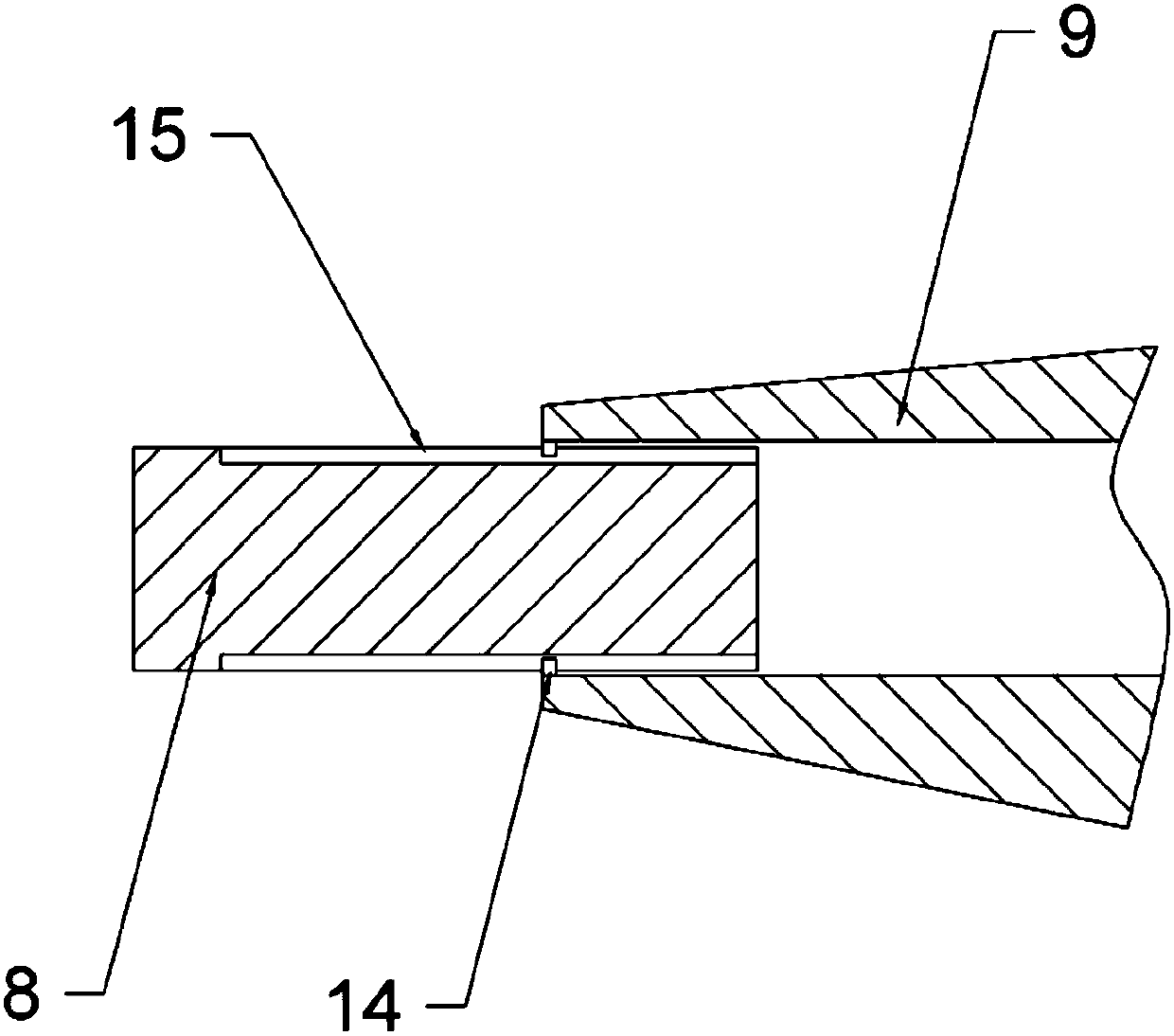

[0016] This embodiment is basically as attached figure 1 Shown: Wire feeding device for knitwear processing, including base 1, bracket 3, motor 2, conveyor belt 10, controller, cylinder 12, nut 13, transmission wheel 9 and bobbin 6, transmission wheel 9 is conical shape, bracket 3 and base 1 is fixedly connected, the motor 2 is fixed on the base 1, and the output shaft of the motor 2 is connected with a rotating rod 8. like figure 2 As shown, the side of the rotating rod 8 is provided with a chute 15 , the transmission wheel 9 is provided with a protrusion 14 , and the protrusion 14 is inserted into the chute 15 and is slidably connected with the chute 15 . The other end of the transmission wheel 9 is fixedly connected with a screw rod 11, the screw rod 11 is threadedly matched with the nut 13, the transmission wheel 9 drives the bobbin 6 to rotate through the transmission belt 10, and the transmission roller 4 is connected with the rotation on the frame, and the eccentric p...

Embodiment 2

[0021] The difference between this embodiment and Embodiment 1 is that the screw is a two-way screw, and both ends of the two-way screw are screwed with nuts. Setting the two-way screw and nut can adjust the tightness of the wire feeding when the wire feeding degree is loose or tight, which is more convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com