Metal U-shaped pressing wire vertical machine structure

A wire-pressing and U-shaped technology, applied in the field of metal U-shaped wire-pressing vertical device structure, can solve the problems of inconvenient adjustment of wire pressing force, wire wear, poor wire guiding and positioning effect, etc. Small friction, improved coding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

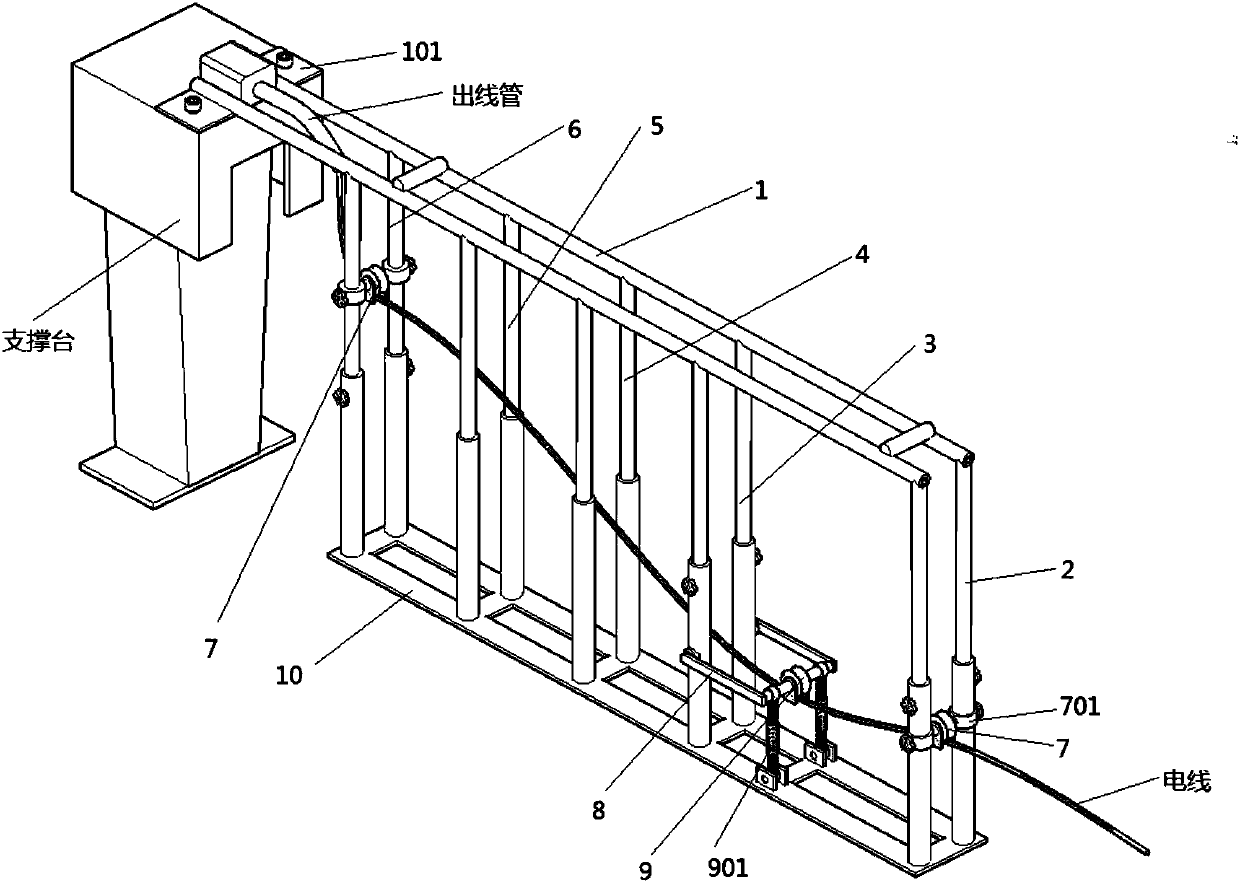

[0023] as attached figure 1 to attach image 3 Shown:

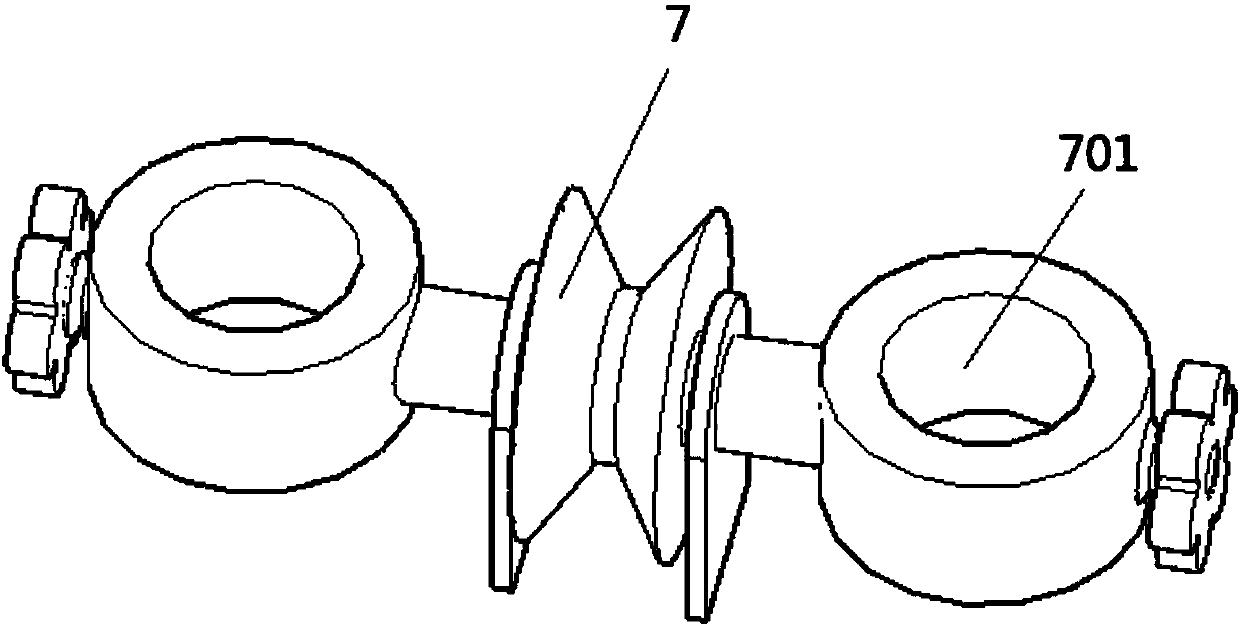

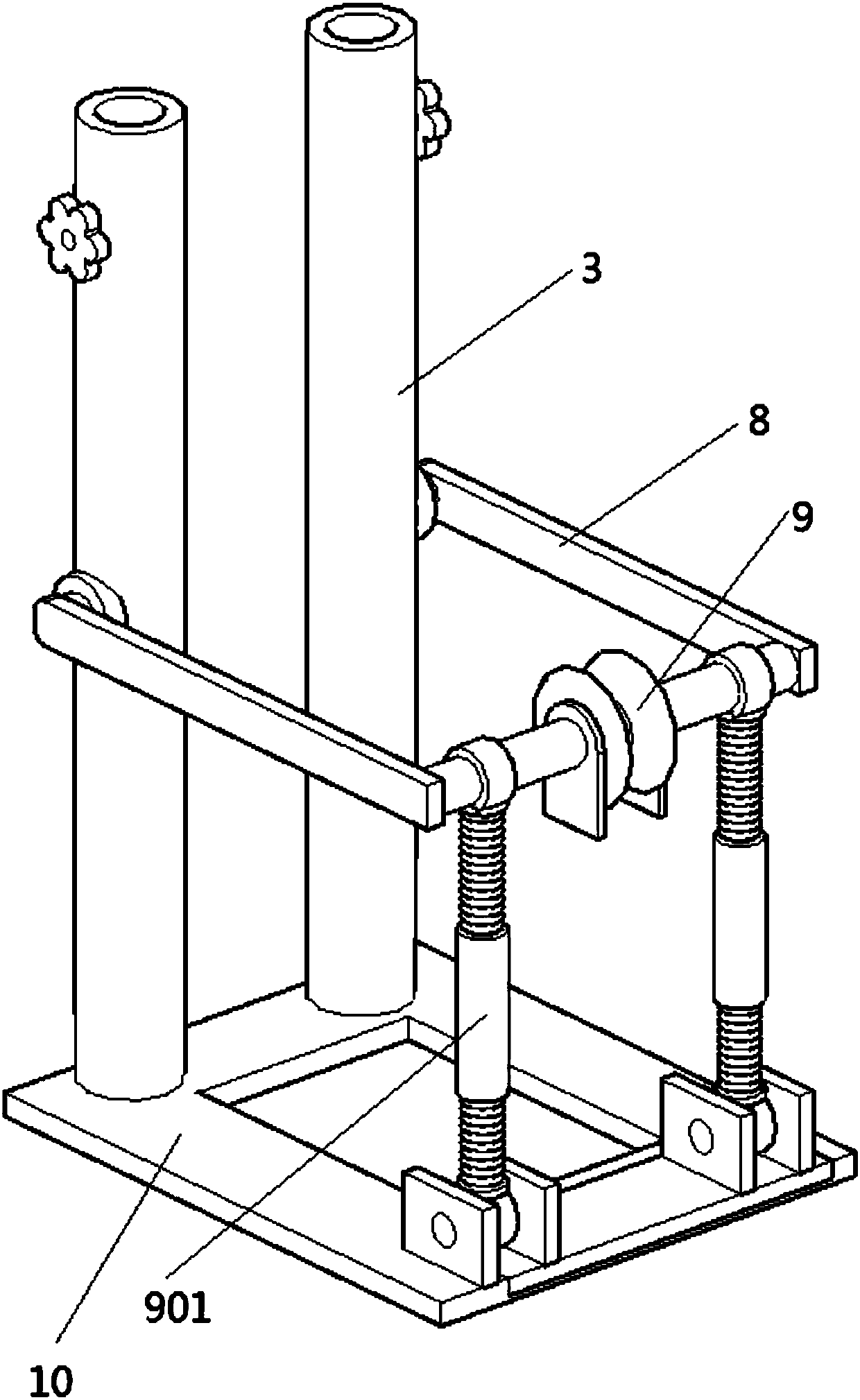

[0024] The present invention provides a metal U-shaped crimping vertical device structure, including a support bar 1, a fixed plate 101, a first support bar 2, a second support bar 3, a third support bar 4, a fourth support bar 5, and a fourth support bar Rod 6, pulley 7, pulley sliding sleeve 701, rotating support rod 8, second pulley 9, double-headed adjusting bolt 901 and base plate 10, the top of the base plate 10 is supported and welded with the first support rod 2 sequentially from left to right, The second support 3, the third support rod 4, the fourth support rod 5 and the fourth support rod 6, wherein the second support 3, the third support rod 4, the fourth support rod 5 and the fourth support rod 6 are equidistantly arranged , the distance between the first support rod 2 and the second support 3 is longer than the distance between the other four support rods; the top end surface of the bottom plate 10 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com