Dust-accumulation power-generation loss prediction-based auxiliary decision-making method of photovoltaic-plant cleaning time

A photovoltaic power station and power generation loss technology, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as reliability, accuracy doubts, dust accumulation power generation loss, etc., and achieve the effect of improving operational efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

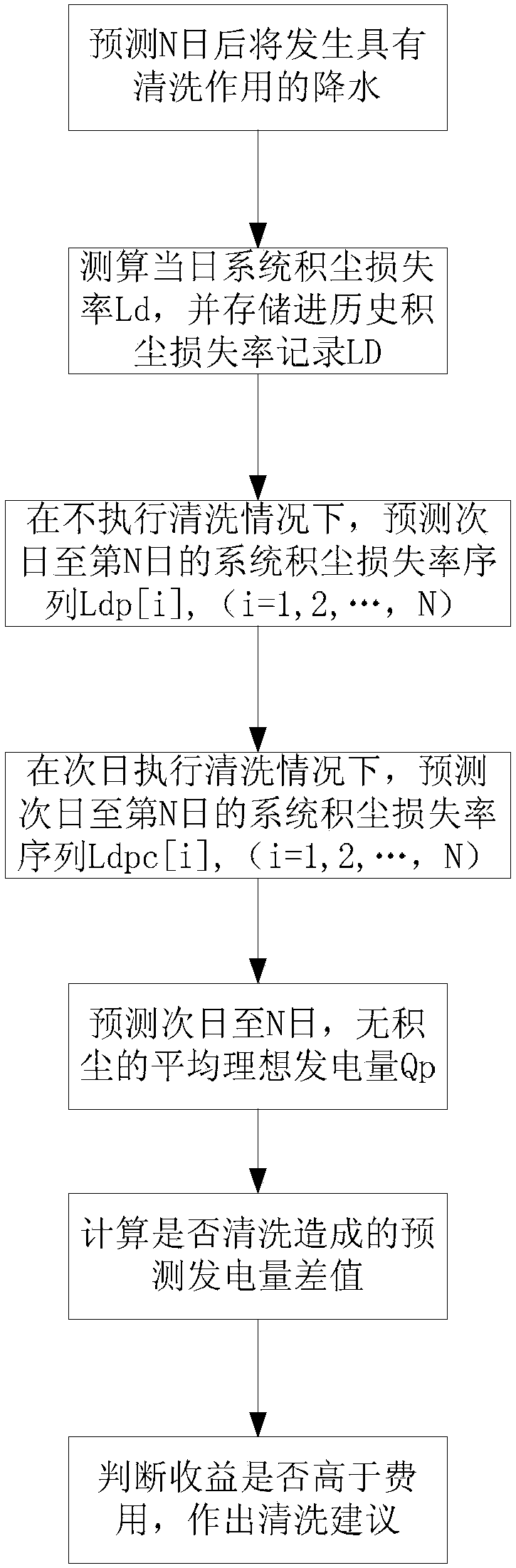

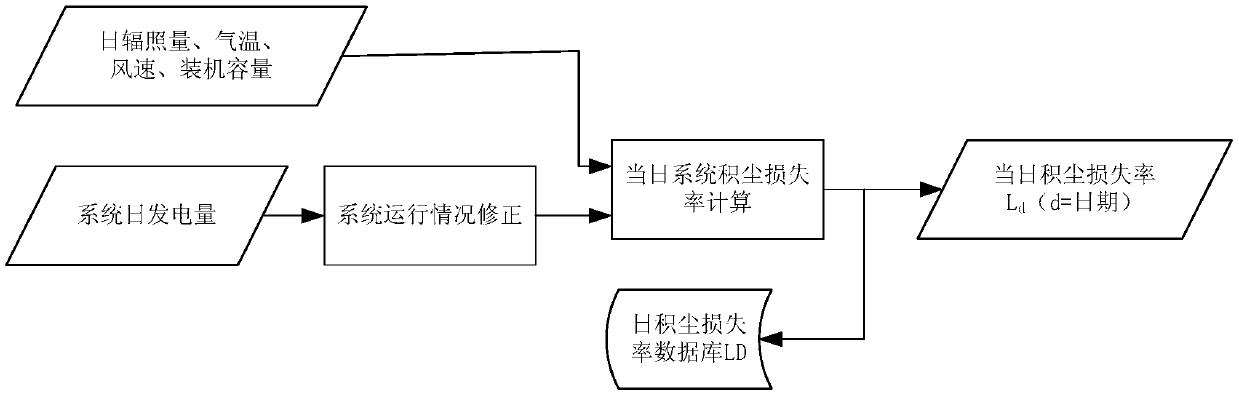

[0040] figure 1 A flow chart of an embodiment of an auxiliary decision-making method for cleaning timing of a photovoltaic power station based on prediction of power generation loss due to accumulated dust is shown.

[0041] The method of the present embodiment comprises the following steps:

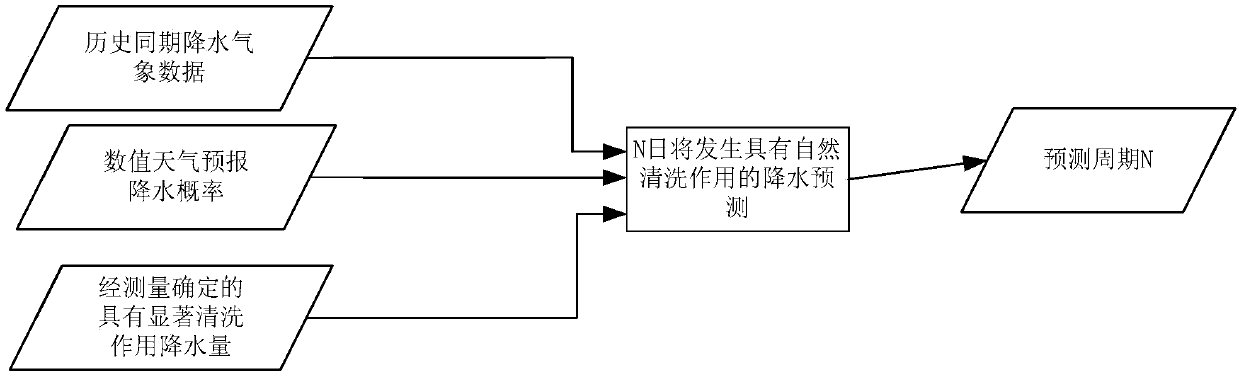

[0042] 1) Predict the number of days N away from the precipitation day with significant cleaning effect; the precipitation day with significant cleaning effect is predicted based on numerical weather forecast and / or historical meteorological records.

[0043] Based on the numerical weather forecast, historical meteorological records, and the measured precipitation parameters required for a significant dust cleaning effect, it is predicted that precipitation with a significant dust cleaning effect will occur after the Nth day, and N is used as the forecast period for subsequent analysis.

[0044] According to the installation form (such as installation inclination angle) of a specific ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com