Magnetic pole assembly and disassembly tool for permanent magnet motor

A technology for permanent magnet motors and loading and unloading tools, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc. It can solve the problems of large energy consumption, long installation time, and inability to use permanent magnet motors on site, so as to save energy , The effect of reducing the time for magnetic steel installation and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] see Figure 1 to Figure 19 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

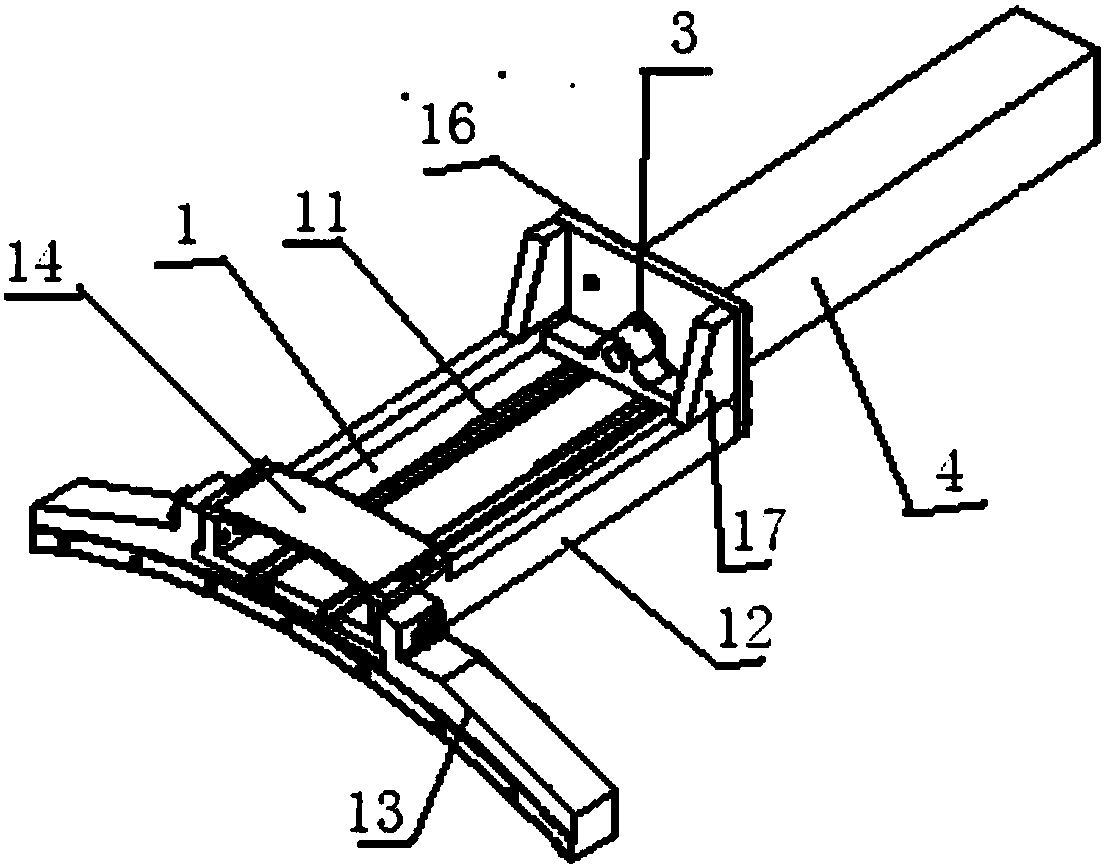

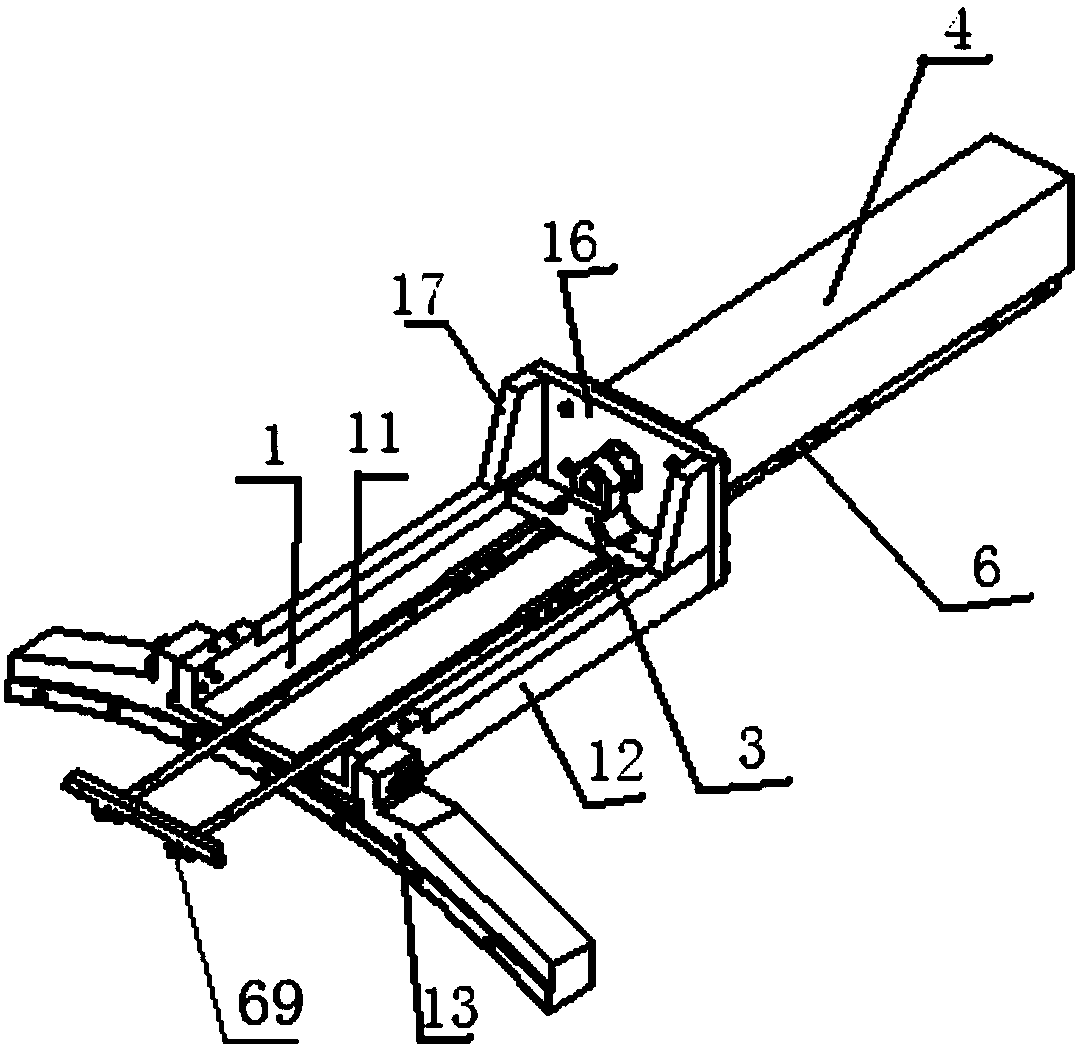

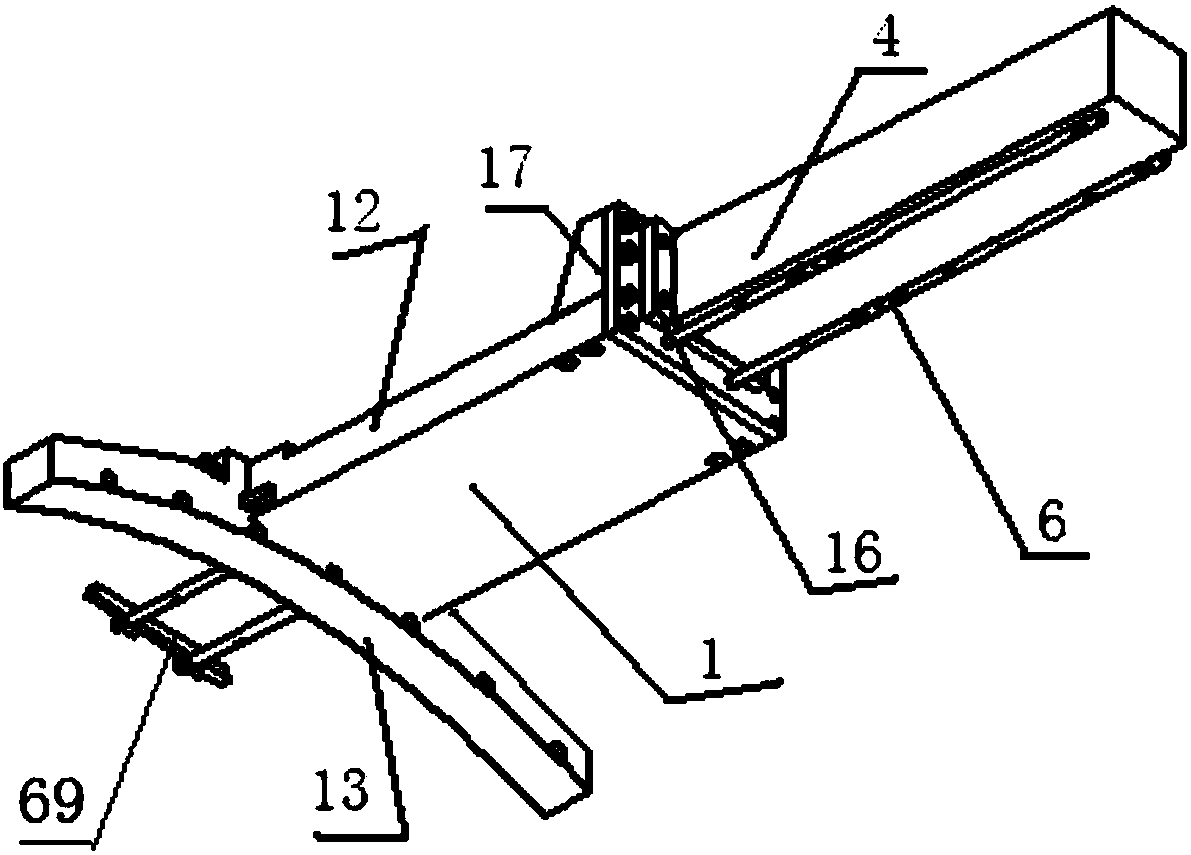

[0038] see Figure 1 to Figure 3 ,as well as Figure 12 to Figure 15 , A permanent magnet motor pole loading and unloading tool of the present invention includes a guide rail plate 1, and two dovetail grooves 11 parallel to the axial direction are arranged on the top surface of the guide rail plate 1. Two sides of the guide rail plate 1 are respectively provided with a guide rail side plate 12 whose top surface is higher than the top surface of the guide rail plate 1 .

[0039] Both sides of the first end of the guide rail plate 1 are respectively provided with an arc-shaped positioning block 13 which can fit and fix the rotor of the permanent magnet motor. The two arc-shaped positioning blocks 13 are attached to the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com