Pneumatic tire

A technology for pneumatic tires and tires, which is applied to tire parts, tire treads/tread patterns, transportation and packaging, etc. It can solve the problems of not being able to fully improve drainage performance, improve wet road performance, and suppress wear resistance performance and partial wear resistance, and the effect of improving drainage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Hereinafter, one embodiment of the first invention of the present invention will be described with reference to the drawings.

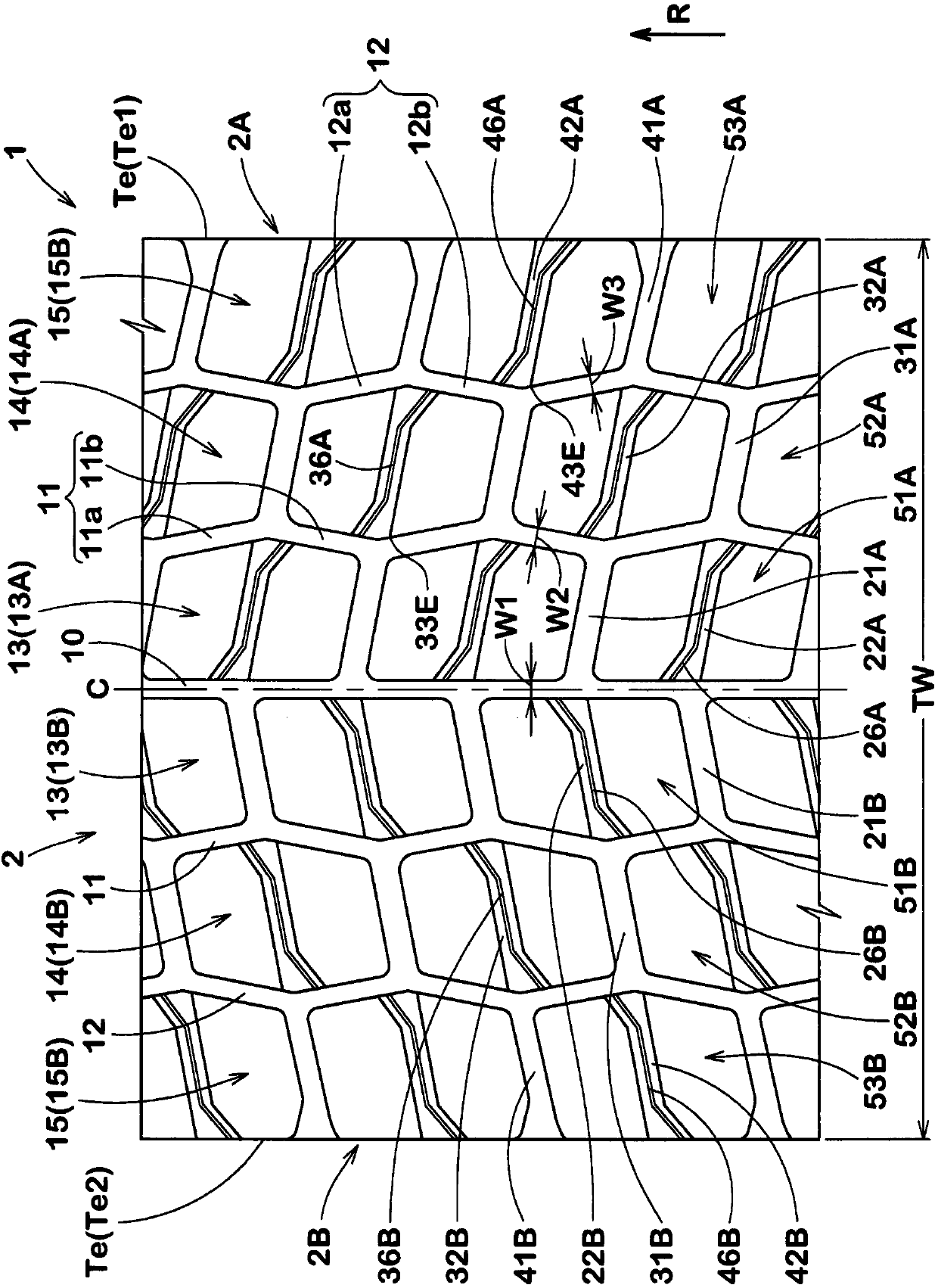

[0031] figure 1 It is a development view of the tread part 2 of the pneumatic tire 1 of this embodiment. The pneumatic tire 1 of the present embodiment is particularly preferably for heavy loads, and has a directional pattern specifying the rotational direction R of the tire on the tread portion 2 . The rotational direction R is indicated by letters, arrows, and the like, for example, on the sidewall portion.

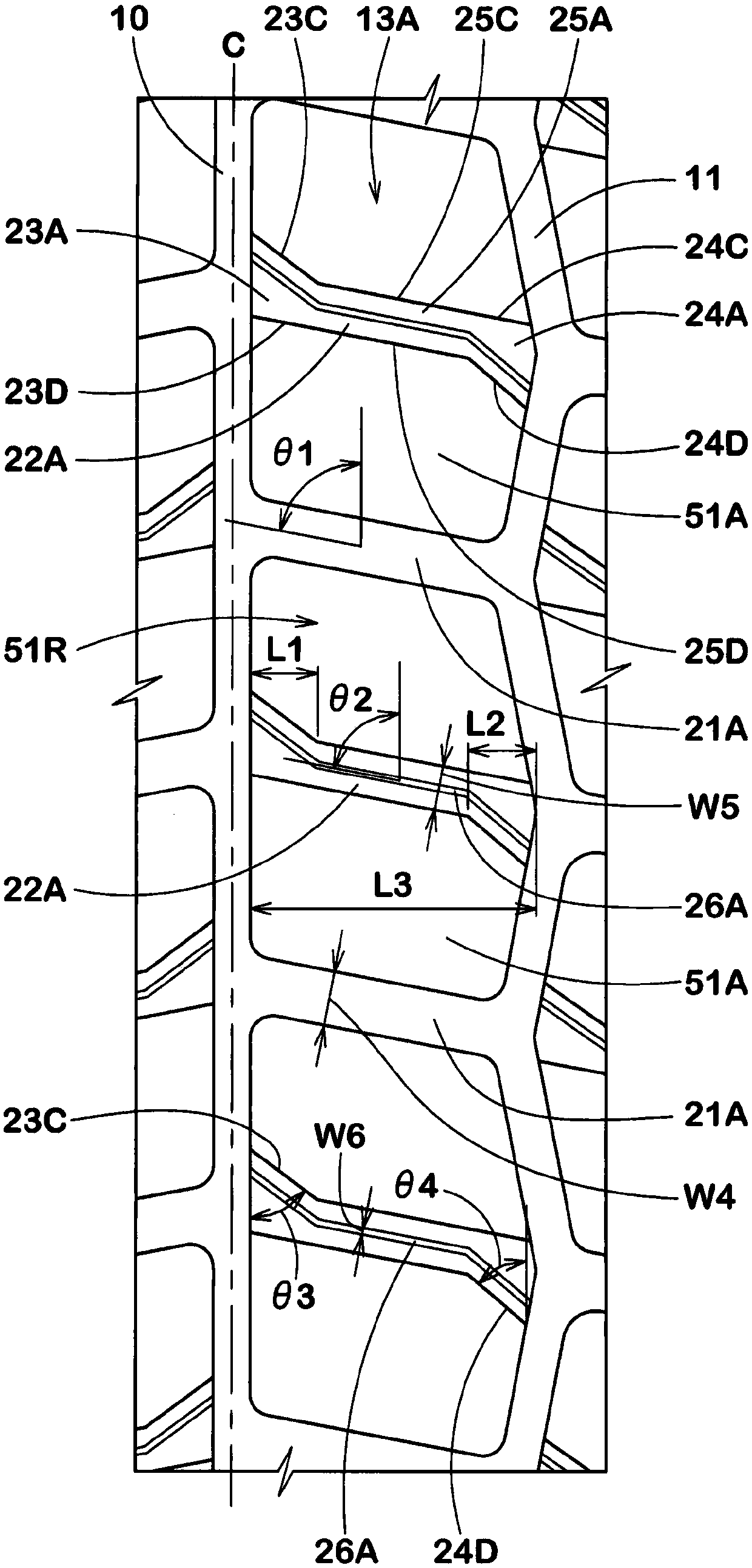

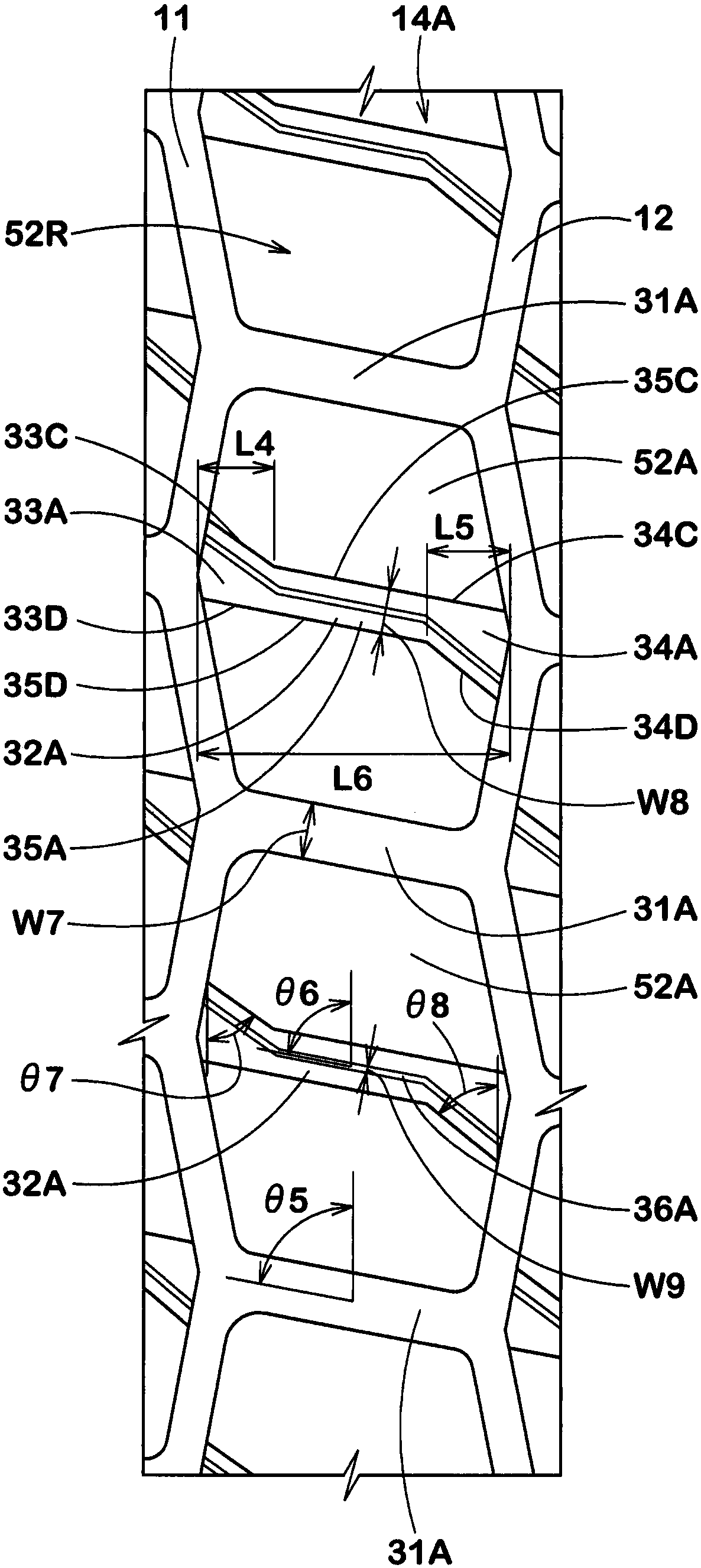

[0032] Formed on the tread portion 2 are: crown main grooves 10 continuously extending in the tire circumferential direction on the tire equator C; a pair of middle main grooves 11 continuously extending in the tire circumferential direction on both sides of the tire equator C; A pair of shoulder main grooves 12 extend continuously along the tire circumferential direction on both sides of the tire equator C. The shoulder main groove 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com