Vehicle-mounted lock fastener structure

A locking and vehicle-mounted technology, applied in vehicle parts, transportation and packaging, etc., can solve the problems of uncontrollable operation force, small disassembly stress, panel deformation, etc., and achieve the effect of simple structure, economical cost, and small assembly and disassembly force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

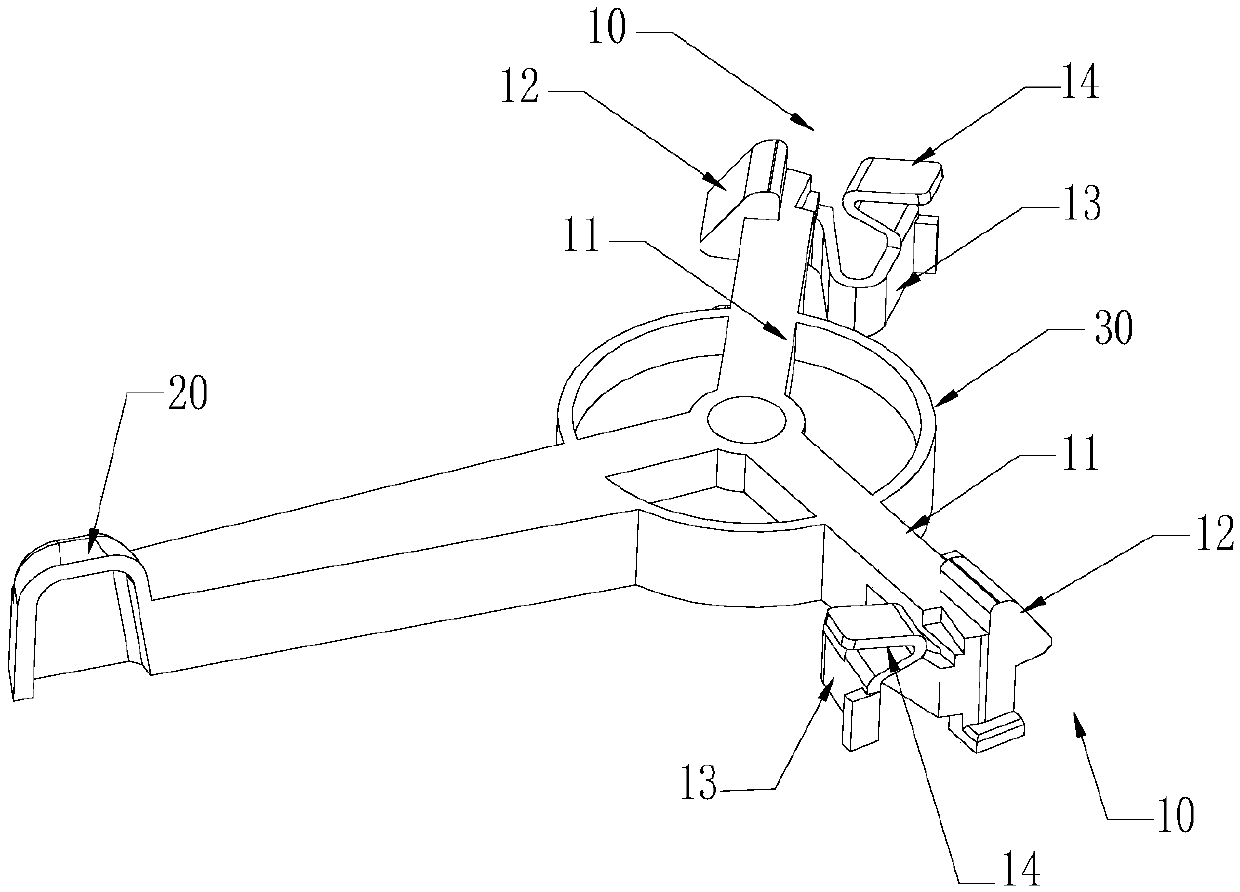

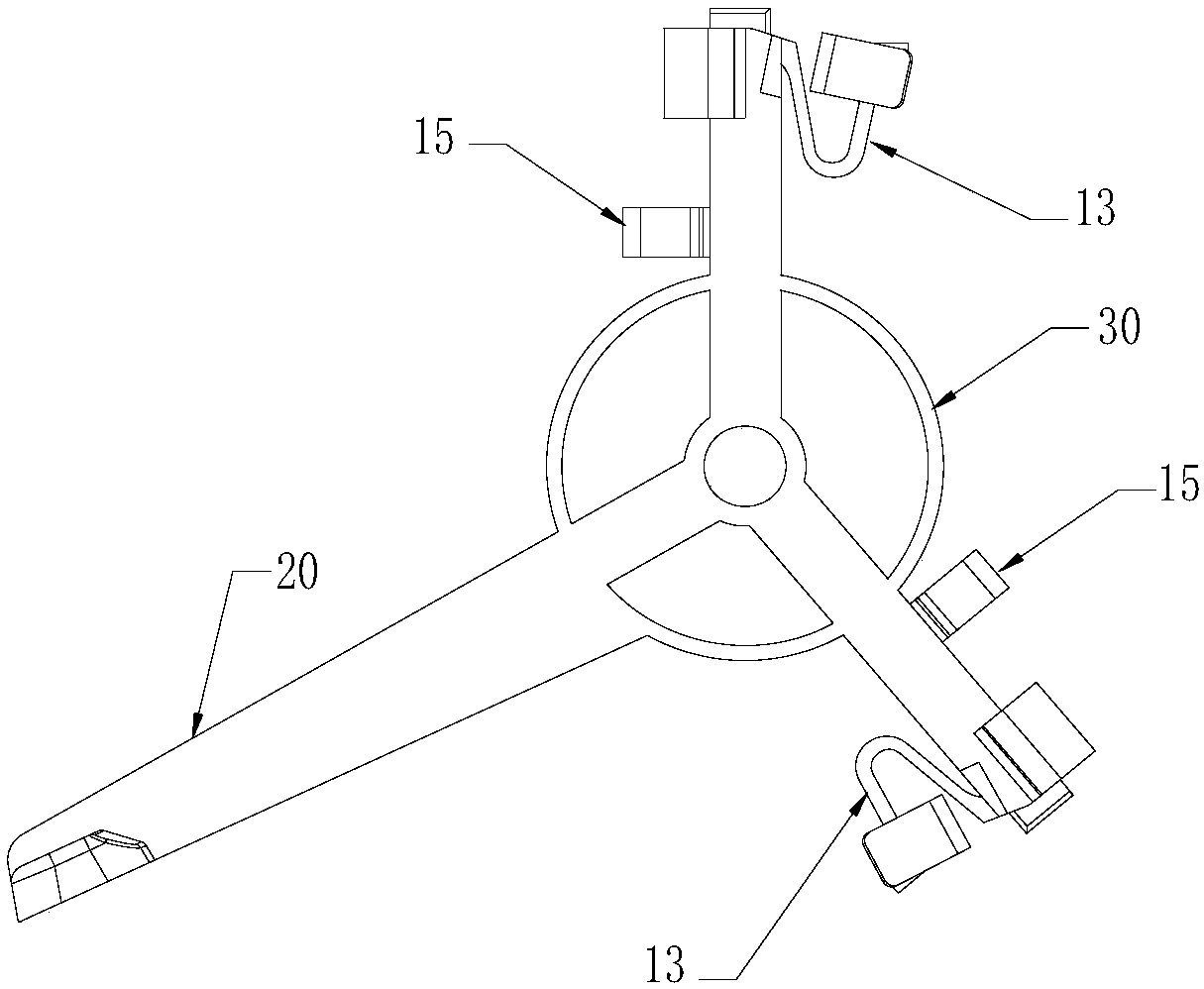

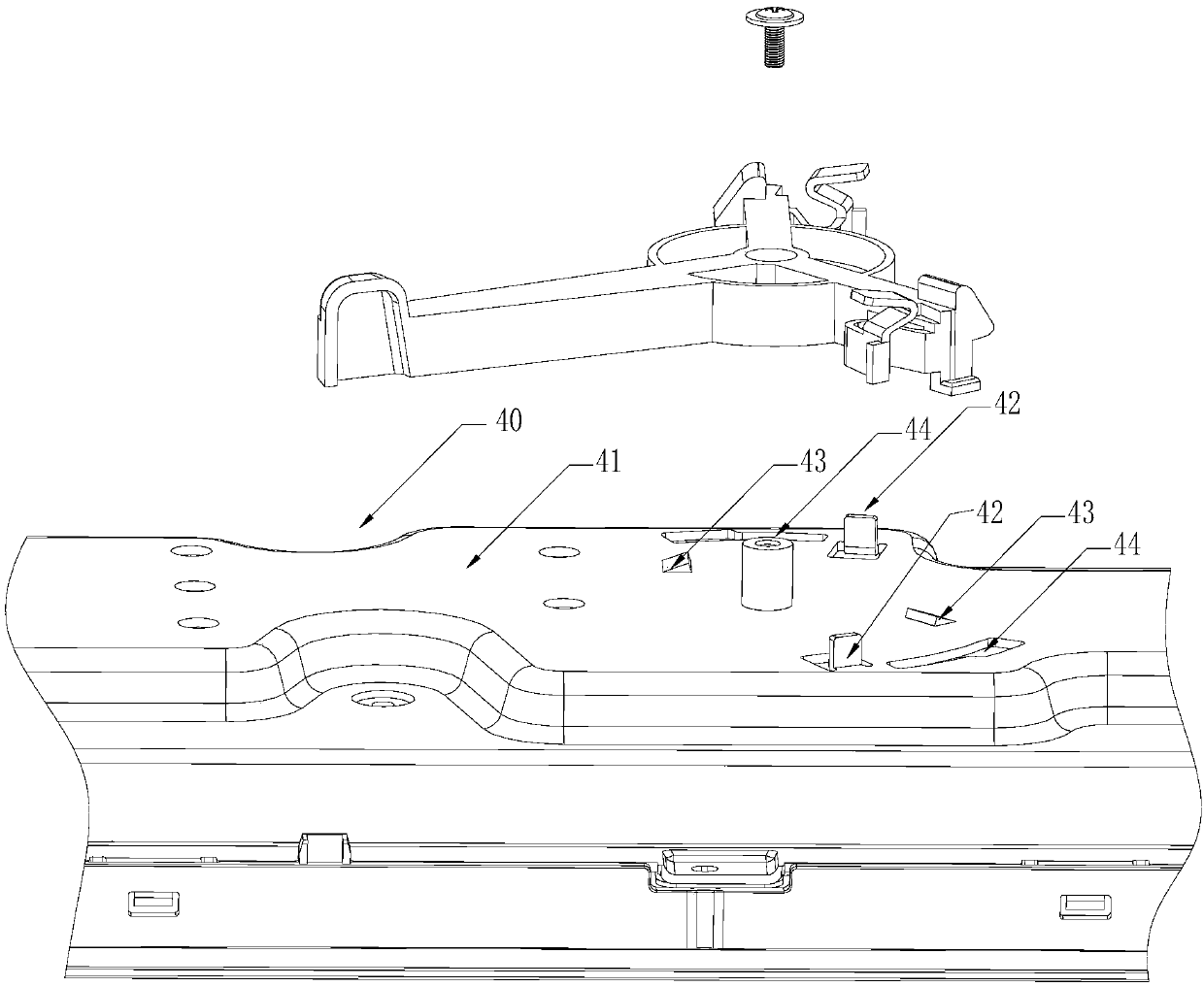

[0020] This embodiment provides a vehicle-mounted locking structure for installation and fixing between the display panel and the center console. The vehicle-mounted locking structure is an integral plastic structural part formed by injection molding. Such as figure 1 with 2 As shown, it includes two buckle ends 10 and a rotating dismounting arm 20, the rotating dismounting arm 20 is connected to the rotating arm 11 of the buckling end 10, and the rotating dismounting arm 20 and the rotating arm 11 can be connected to each other. Design a certain included angle according to the design space. Wherein, the buckle end 10 includes a buckle block 12, and the back side of the buckle block 12 is provided with a button-in pre-compression elastic arm 13, and the button-in pre-compression elastic arm 13 is provided with an ejection spring arm 14, and It includes a turntable frame 30 on which the rotating arm 11 and the rotating dismounting arm 20 of the buckle end 10 are fixed. An an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com