Colored plastic mobile phone rear cover manufacturing process

A mobile phone back cover and manufacturing process technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problems of dispersion and loss of coating color difference, and no protective measures for the edge of colored plastic mobile phone back cover, so as to save process and improve Efficiency and the effect of improving product pass-through rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

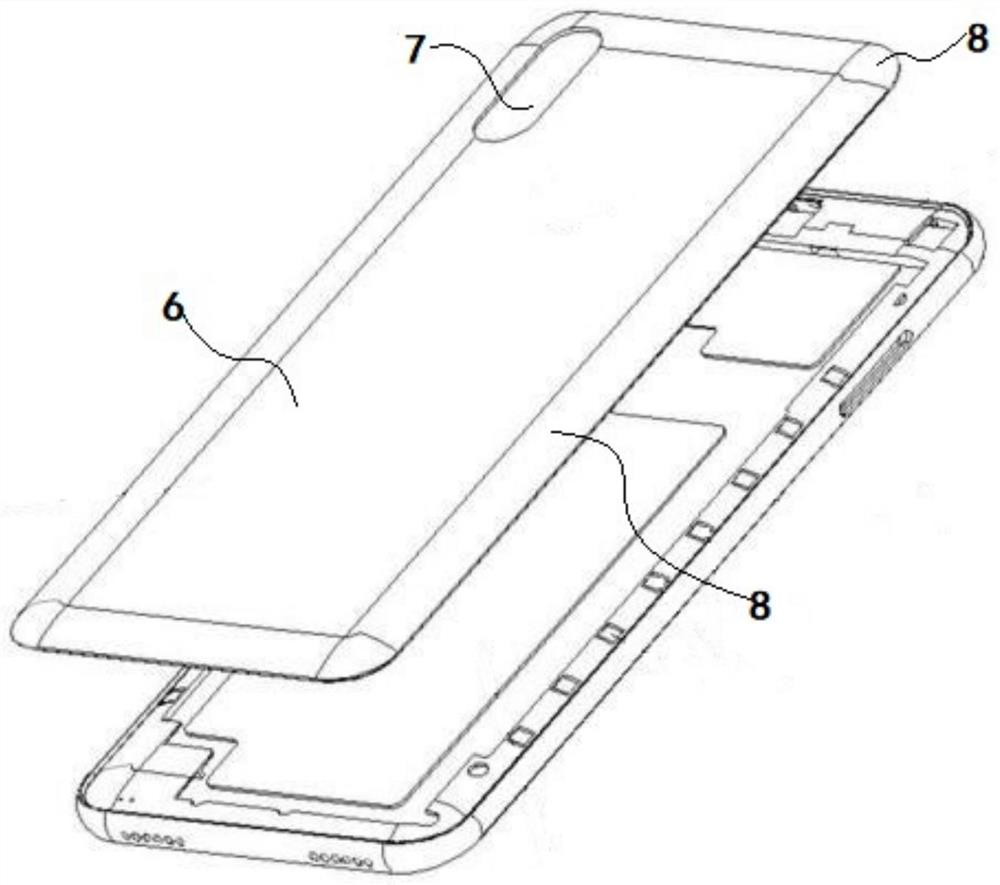

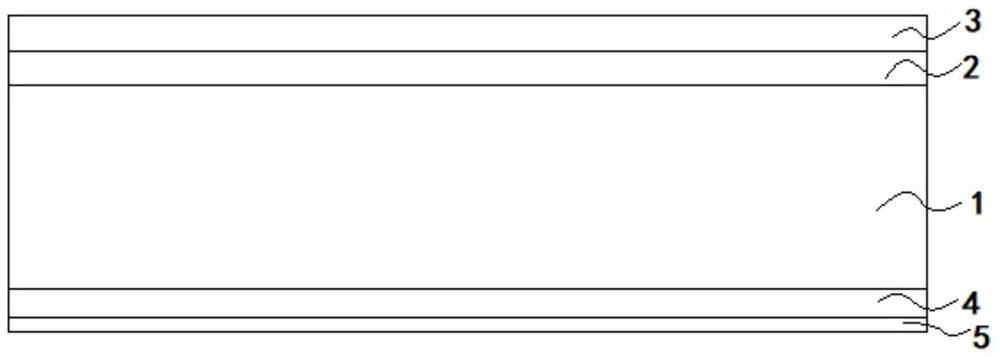

[0029] like Figure 1-4 As shown, there are holes 7 for installing the camera on the back cover 6 of the colored plastic mobile phone, and four corners and four sides of the back cover 6 of the colored plastic mobile phone are provided with reinforcing ribs 8 that are fixedly connected, and the reinforcing ribs 8 and the back cover of the colored plastic mobile phone are provided 6 Seamlessly fixed connection or integral molding, the reinforcing ribs 8 arranged on the four corners of the colored plastic mobile phone back cover 6 are rectangular, and the reinforcing ribs 8 disposed on the four sides of the colored plastic mobile phone back cover 6 are in the shape of a "well" as a whole. The reinforcing rib 8 is made of transparent plastic or glass. In this embodiment, the reinforcing rib 8 and the colored plastic mobile phone back cover 6 are seamlessly and fixedly connected, and the reinforcing ribs 8 at the four corners of the colored plastic mobile phone back cover 6 in thi...

specific Embodiment approach 2

[0031] The main difference between the second embodiment and the first embodiment is:

[0032] (1) In this embodiment, the reinforcing ribs 8 and the colored plastic mobile phone back cover 6 are integrally formed.

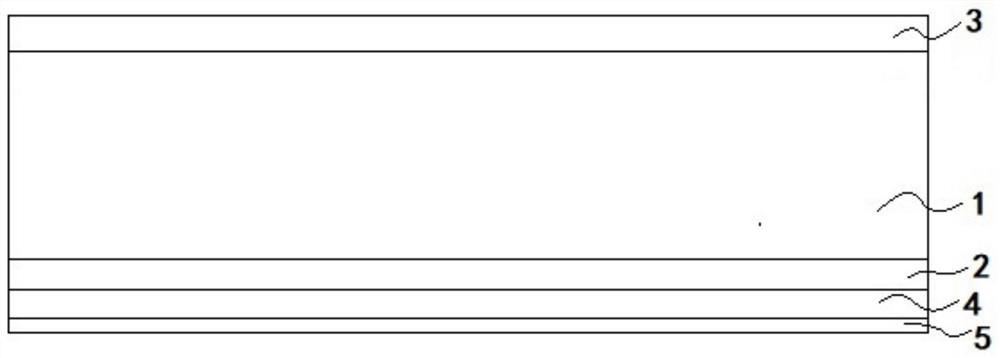

[0033] (2) If image 3 As shown, in this example, the texture layer 2 is arranged on the inner surface of the outer shell layer 1, that is, in contact with the reflective layer 4; the thickness of the outer shell layer 1 is 5 mm, the thickness of the functionalized coating layer 3 is 40 μm, and the colored plastic mobile phone back cover The L*a*b* value of is overall white.

specific Embodiment approach 3

[0034] The main difference between the third embodiment and the first embodiment is:

[0035] (1) In this embodiment, the reinforcing ribs 8 and the colored plastic mobile phone back cover 6 are integrally formed.

[0036] (2) If Figure 4 As shown, in this example, the textured layer 2 is arranged on both sides of the outer shell layer 1, that is, the textured layer 2 is in contact with the reflective layer 4 and the hardened coating 3 respectively; the thickness of the outer shell layer 1 is 2.5 mm, and the functionalized coating 3 The thickness is 20um, and the L*a*b* value of the colored plastic mobile phone back cover 6 is generally blue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com