Graded crushed stones for flexible base of highway pavement and preparation method of graded crushed stones

A technology of graded crushed stone and flexible base, which is applied to roads, roads, on-site paved concrete pavement, etc., can solve the problems of increasing construction cost, difficulty in compaction, and affecting construction efficiency, so as to save costs and control Effect of reflecting cracks and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in combination with specific embodiments.

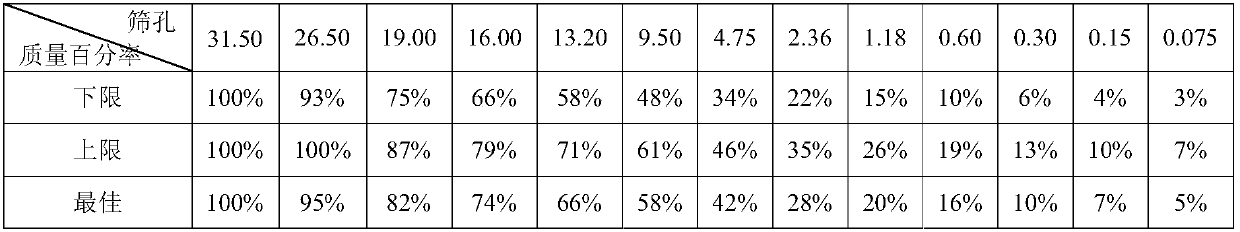

[0025] The invention proposes a graded crushed stone for a flexible base course of a highway pavement, wherein the lithology of the parent rock of the graded crushed stone is a regional metamorphic rock, which develops in a schistose and gneiss structure.

[0026] As the raw material of graded crushed stone, regional metamorphic rock has a relatively large proportion of needle-like particles, which is easy to segregate and difficult to compact during paving construction, and may have defects such as large instantaneous deformation under load. Therefore, there are higher requirements for the quality of the graded crushed stone mainly composed of regional metamorphic rocks and the preparation method of the graded crushed stone.

[0027]There are many physical and technical indicators that affect the quality of graded crushed stone, including raw material crushing index value,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com