Diamond compact coring bit facilitating drainage in drilling process

A technology of diamond composite sheets and coring bits, which is applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of small size of drainage gap, unfavorable drainage, and slow drilling speed, so as to improve the speed of footage and improve market competition. The effect of force, formation core convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

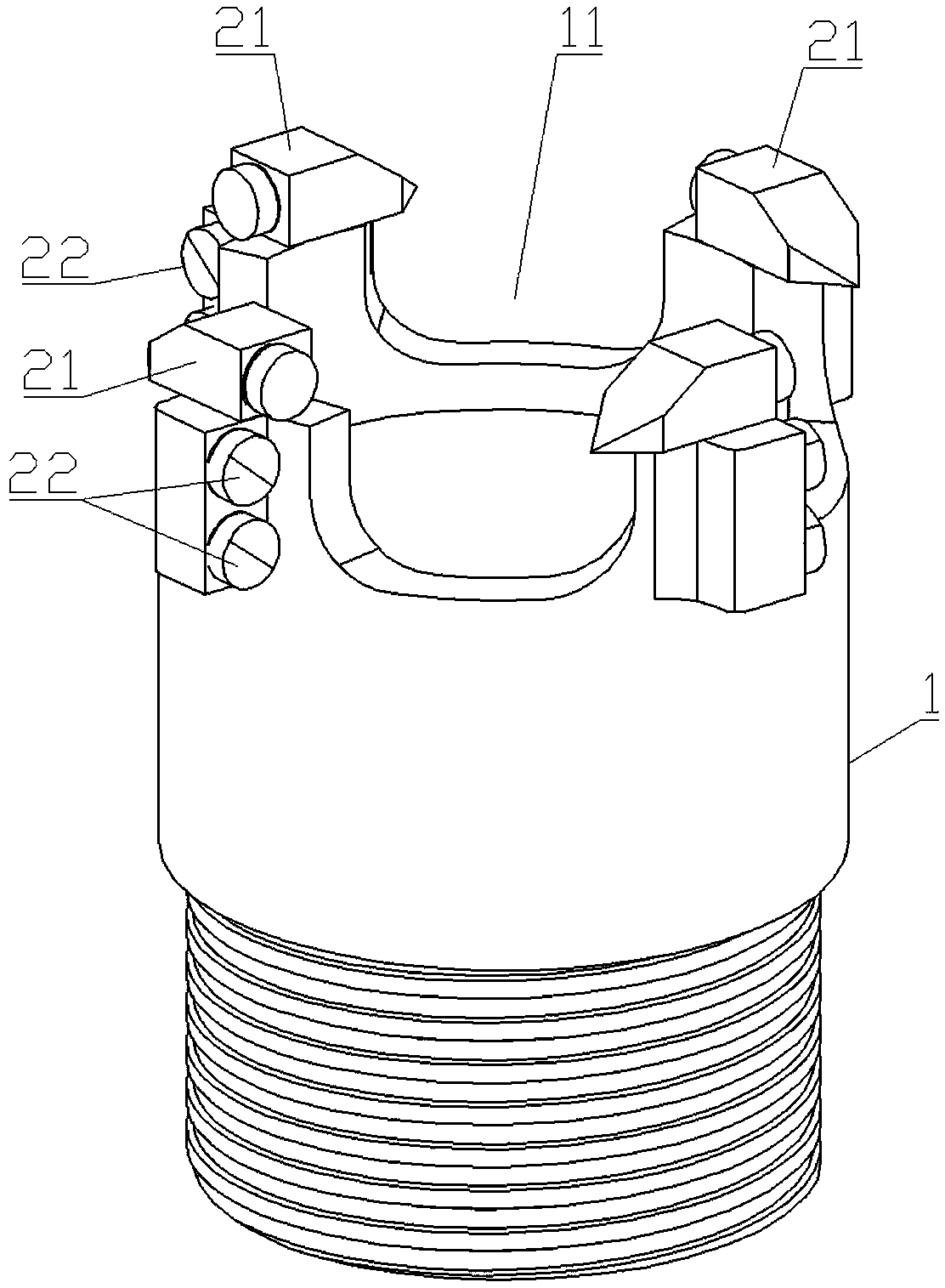

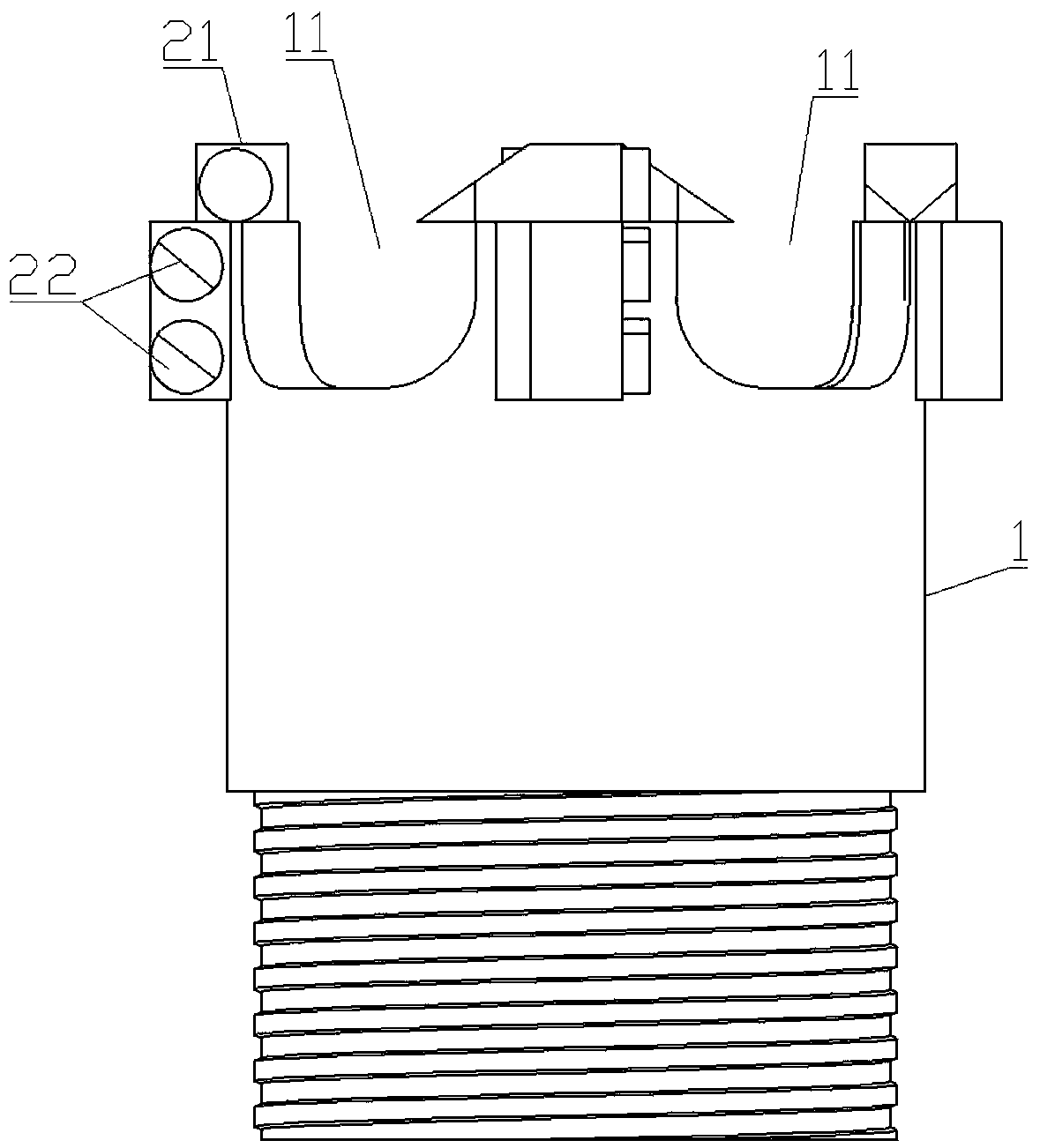

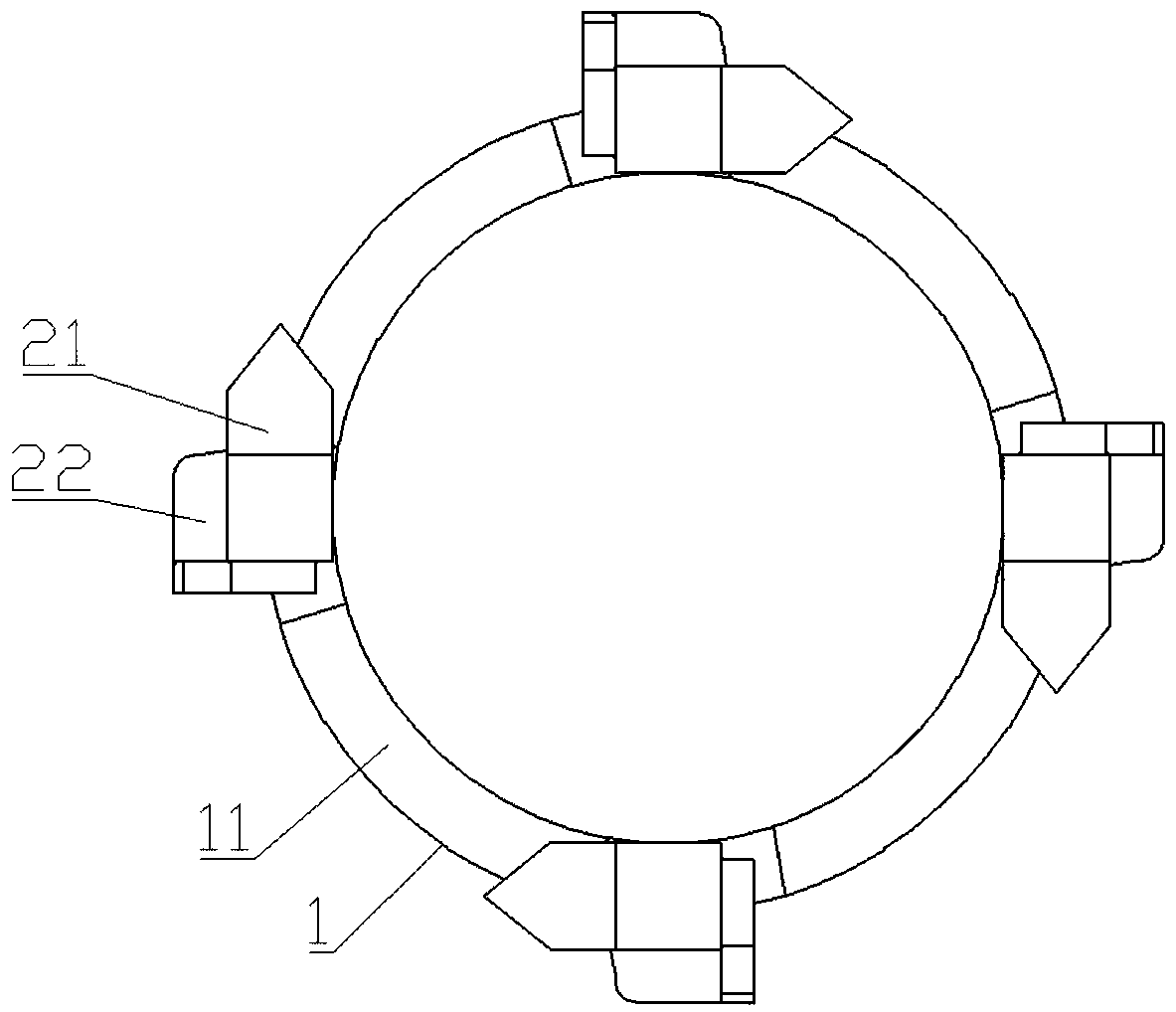

[0022] Such as Figure 1-3 As shown, the diamond composite chip core drill bit that facilitates water drainage during drilling includes a steel body 1 and cutting teeth.

[0023] The steel body 1 is in the shape of a sleeve, one end of which is the first end connected with the drilling equipment, and the other end is the second end connected with the cutting teeth. The steel body 1 is provided with drainage openings 11 in the region between adjacent cutting teeth A21.

[0024] There are 3-5 groups of cutting teeth, and each group of cutting teeth is evenly distributed on the second end of the steel body 1 in a ring shape; one group of cutting teeth includes one cutting tooth A21 and at least one cutting tooth B22, and the cutting tooth A21 is fixed on the steel body 1 On the end surface of the second end of the steel body 1, the cutting teeth B22 are fixedly connected to the outer wall of the second end of the steel body 1, and are closely adjacent to the cutting teeth A21 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com