Clamping hoop for installation of support at construction site

A technology for construction and installation, applied in the connection of rods, connecting components, mechanical equipment, etc., can solve the problems of reducing bolt tightness, troublesome clamp installation, screw corrosion and other problems, to simplify installation steps, avoid screw bolts, etc. The effect of rusted teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

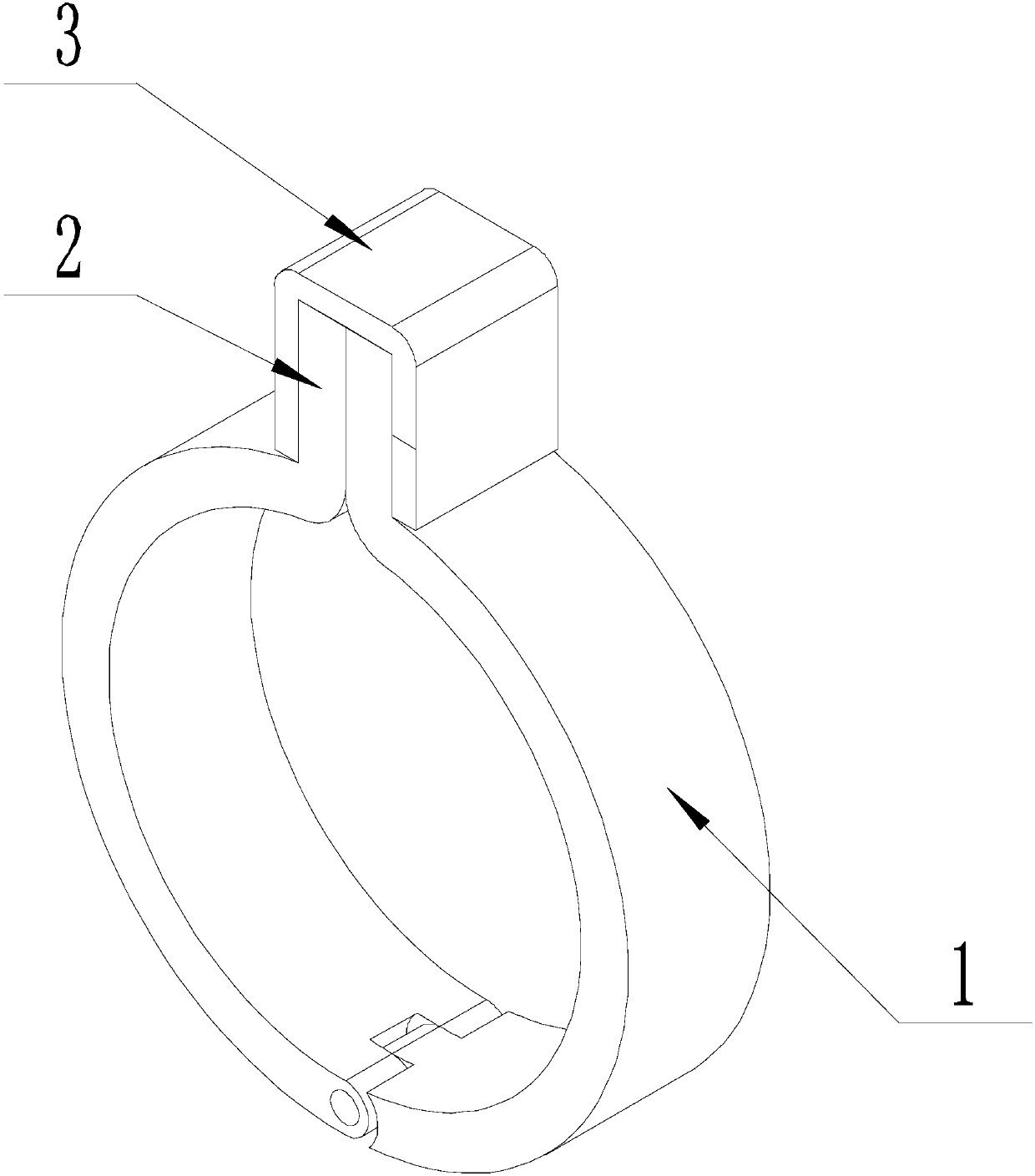

[0032] like Figure 1-Figure 7 As shown, the present invention is used for the bracket installation of the building construction, including a clamp body, and the clamp body includes two semicircular clamp pieces 1, one end of the clamp piece 1 is hinged to each other, and the other end is both Ears 2 are provided, and retaining parts 3 are also included. The retaining members 3 are U-shaped. The opposite sides are respectively in contact with an inner wall of the retaining member 3, and the lugs 2 and the retaining member 3 have an interference fit, that is, the distance between the ends of the inner surface of the retaining member 3 is smaller than the distance between the two opposite surfaces after the lugs 2 are in contact with each other. spacing.

[0033] Rotate the clamp piece 1 around the hinge axis to increase the distance between the lugs 2, then set the clamp piece 1 on or around the pipe, and then put the lugs 2 close to each other, and then place the clamping pie...

Embodiment 2

[0035] This embodiment is based on Embodiment 1 to further illustrate the present invention.

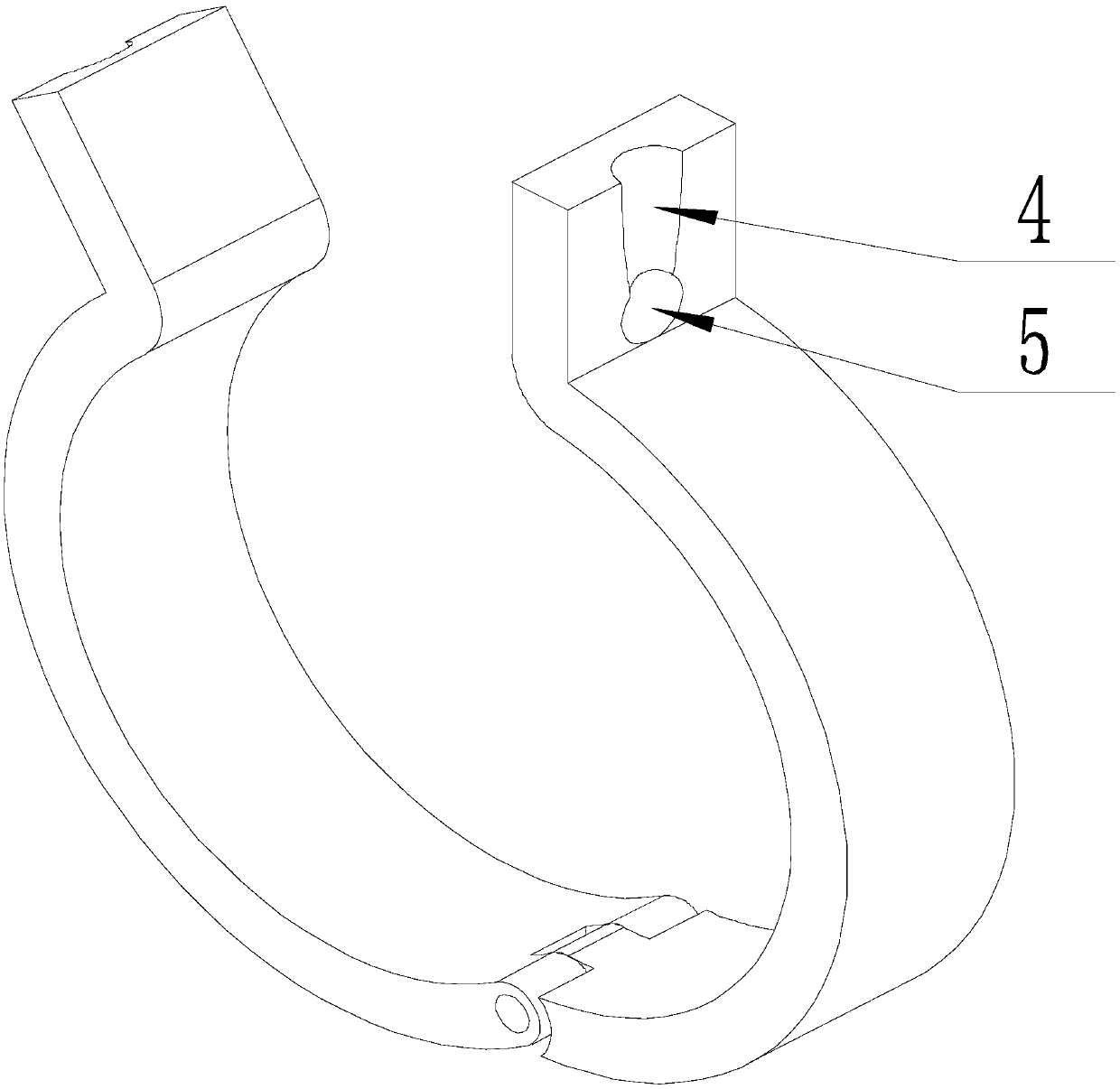

[0036] like Figure 1-Figure 7 As shown, the present invention is used for the bracket installation of the building construction. Guide grooves 4 are arranged on the opposite sides of the lugs 2. The axis at , and the depth of the guide groove 4 gradually decreases as it approaches the center of the clamp piece 1;

[0037] One end of the guide groove 4 close to the center of the clamp member 1 is provided with a clamping groove 5, and the depth of the clamping groove 5 is greater than the minimum depth of the guide groove 5;

[0038] Blocks 6 are arranged at the end of the inner wall of the retaining member 3, and the blocks 6 are respectively matched with a guide groove 4 and moved along the axis of the guide groove 4. When the block 6 is inserted into the groove 5, the support The ears 2 are all snapped into the inner concave surface of the locking member 3 .

[0039] The settin...

Embodiment 3

[0044] This embodiment is based on Embodiment 1 to further illustrate the present invention.

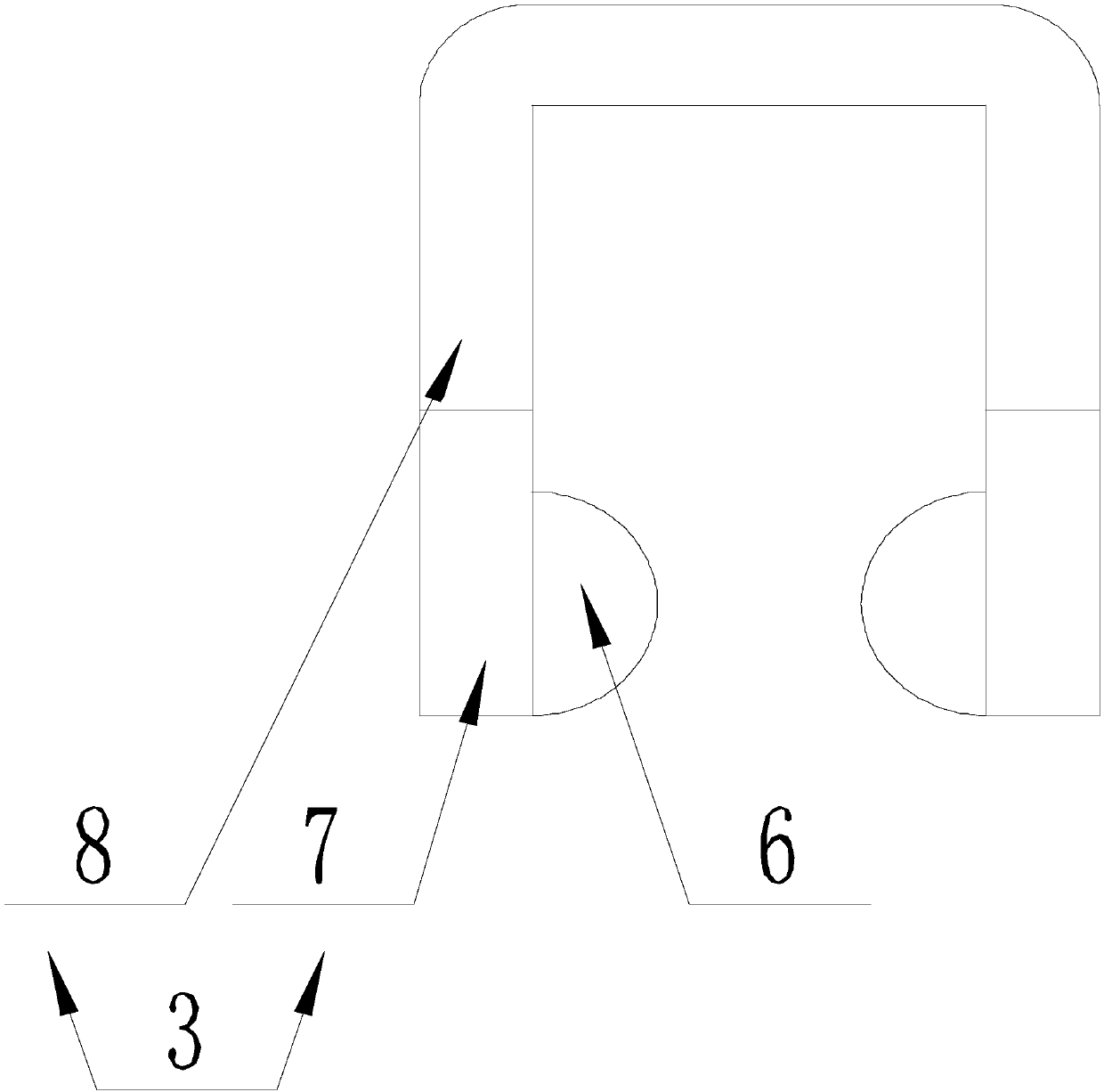

[0045] like Figure 1-Figure 7 As shown, the present invention is used for the bracket installation of the building construction, and the elasticity of the two ends 7 of the locking member 3 is greater than the elasticity of the connecting part 8 in the middle. In order to facilitate the clamping of the clamping part 3 on the lug 2, it is necessary to increase the distance between the two ends of the clamping part 3 so as to match it with the lug 2; and if the clamping part 3 is integrated If the elasticity is set to be consistent, then when the clamping part 3 is clamped on the support ear 2, the limiting force of the intermediate connection part 8 of the clamping part 3 on the support ear 2 is small, and the support ear 2 will wrap around the hoop 1. Under the action of the covered pipes, the two ends of the clamping part 3 will be deformed and pushed away, so that the clamping pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com