Process for preparing propylene polymer composition

A technology of propylene polymer and composition, which is applied in the field of olefin polymerization, and can solve problems such as the introduction of comonomers with low XS values that have not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

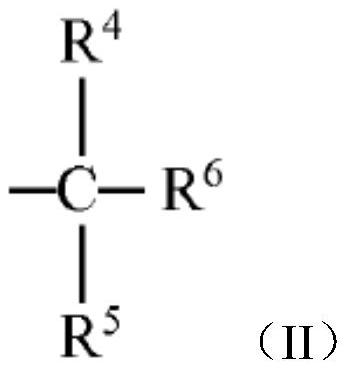

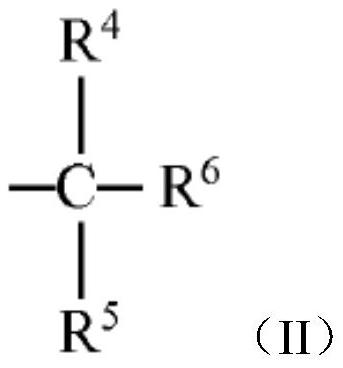

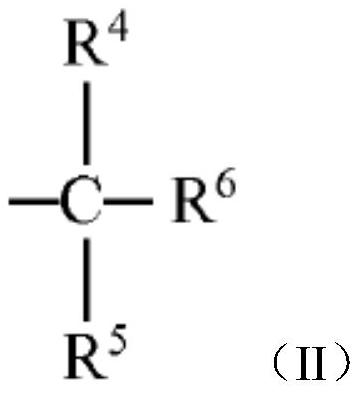

Method used

Image

Examples

Embodiment Construction

[0135] example

[0136] test methods

[0137] If not indicated otherwise, the parameters mentioned in this application were determined by the methods outlined below.

[0138] 1. Determination of comonomer content by IR spectroscopy

[0139] The 1-butene content was determined by quantitative Fourier transform infrared spectroscopy (FTIR) as described below.

[0140] Before the assay, the stabilized powder was compressed in a press as follows:

[0141] Press settings to homogenize the material:

[0142] - Pressing temperature: 210°C

[0143] - Melting time: 90 seconds

[0144] -Cooling rate: 12°C / min

[0145] -Demolding temperature: between 35 and 45°C

[0146] step 1 2 (cooling) Duration (seconds) 90 900 temperature(℃) 210 30 pressure (bar) 0 0

[0147] Press settings for IR tablets:

[0148] - Pressing temperature: 210°C

[0149] - Melting time: 45 seconds

[0150] - Compression pressure: 3 steps (10 / 30 / 90 bar)

[0151] -Coolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com