Ditching equipment for vegetable cultivation

A vegetable and equipment technology, applied in the field of ditching equipment for vegetable planting, can solve problems such as wear and tear, achieve the effects of low energy consumption, prolong service life, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

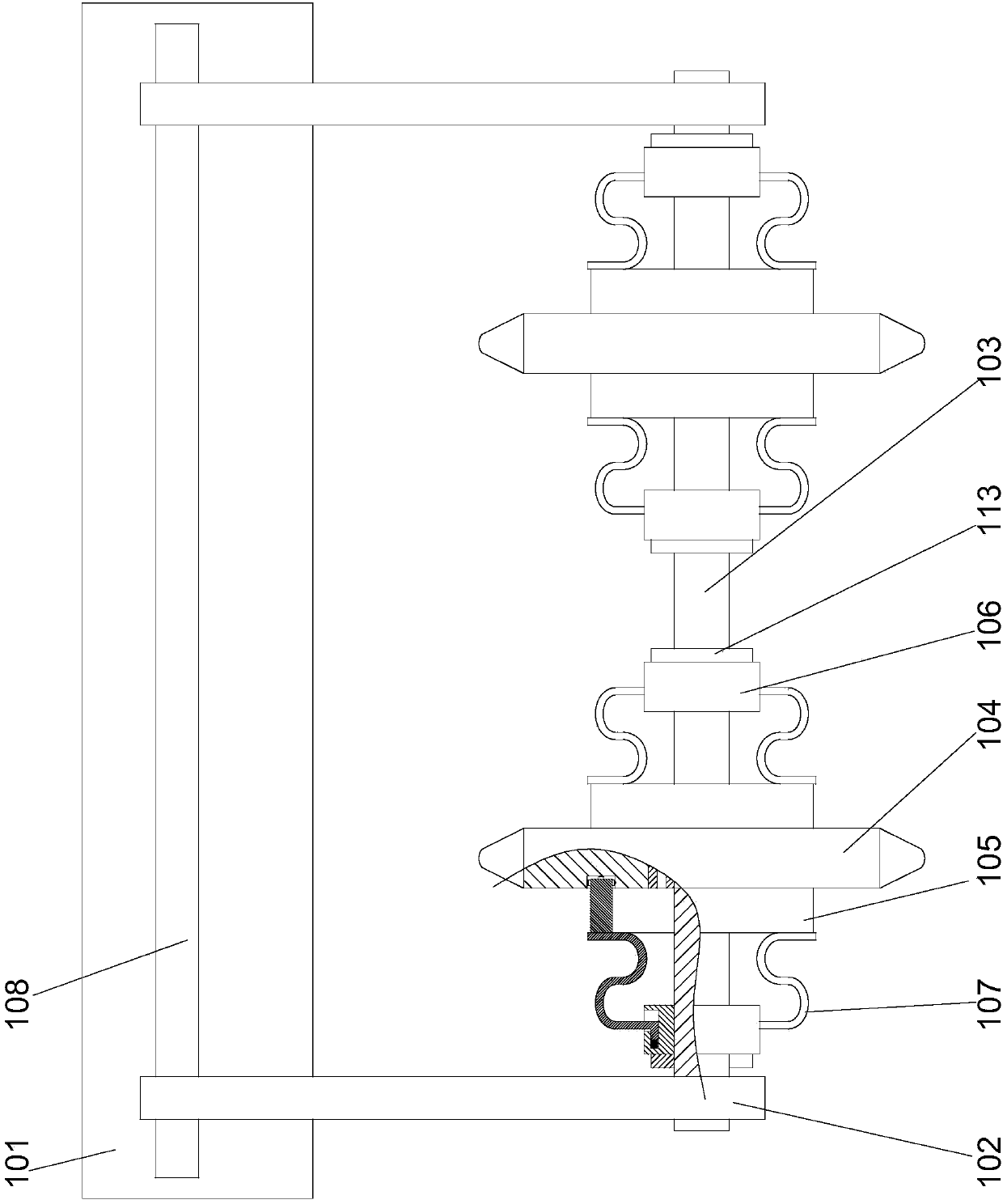

Embodiment 1

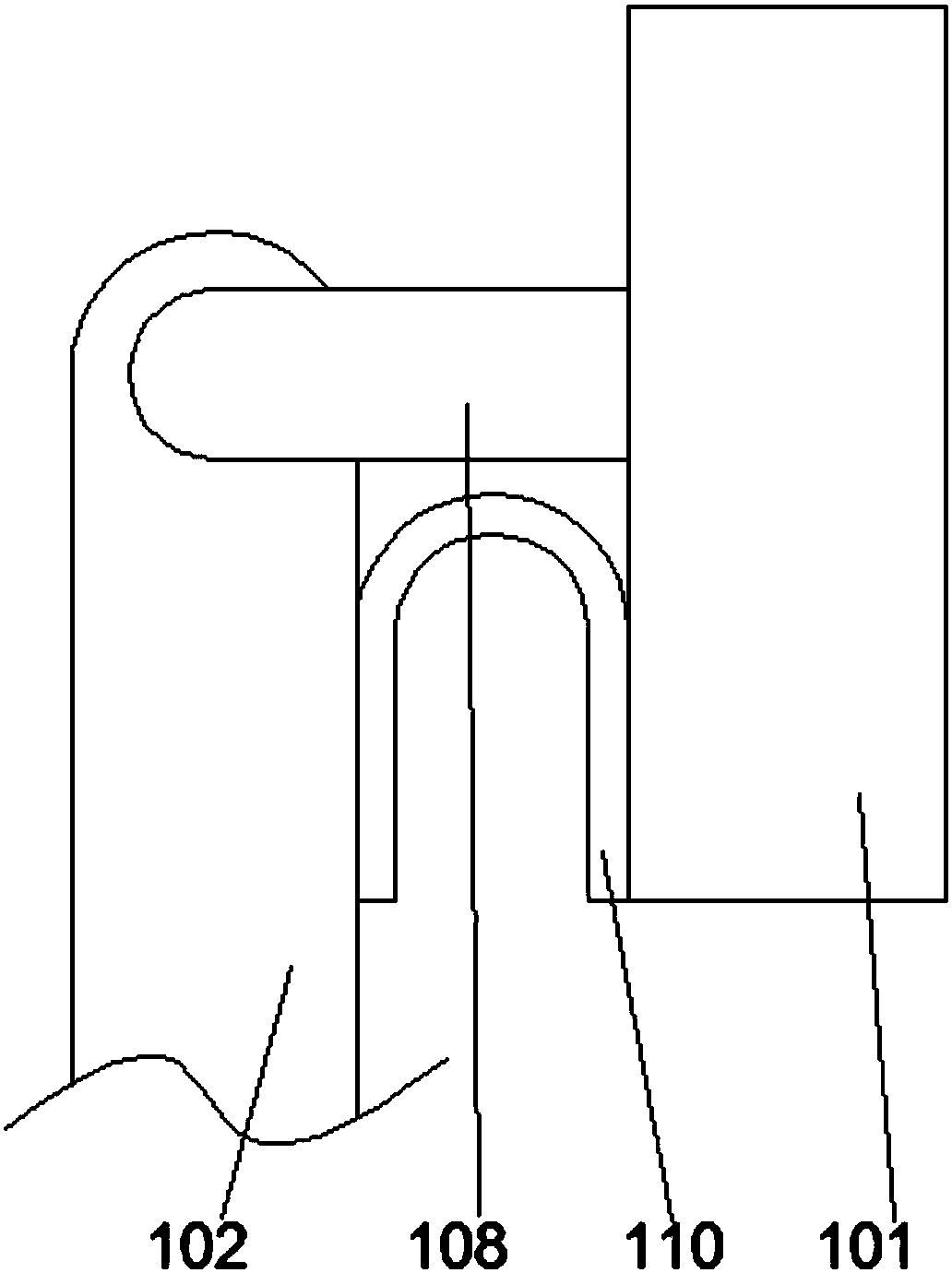

[0026] In order to facilitate the installation of the vertical beams, in this embodiment, preferably, a cross beam 108 is arranged on the mounting plate 101, and the upper end of the vertical beam 102 is connected to the cross beam 108 through a bearing in rotation. The mounting plate 101 is provided with a fixing plate 110, one end of the fixing plate 110 is fixedly connected to the mounting plate 101, and the other end of the fixing plate 110 is fixedly connected to the vertical beam 102 facing the On one side end surface of the mounting plate 101 . During installation, the two ends of the beam are fixedly connected to the mounting plate, and the upper end of the vertical beam is rotated and connected to the beam, so that the fixed plate connects the vertical beam and the mounting plate to each other. Under the action of the fixed plate and the beam, the overall structure is more stable. It is stable, and can improve the stability and firmness of the upper end of the vertica...

Embodiment 2

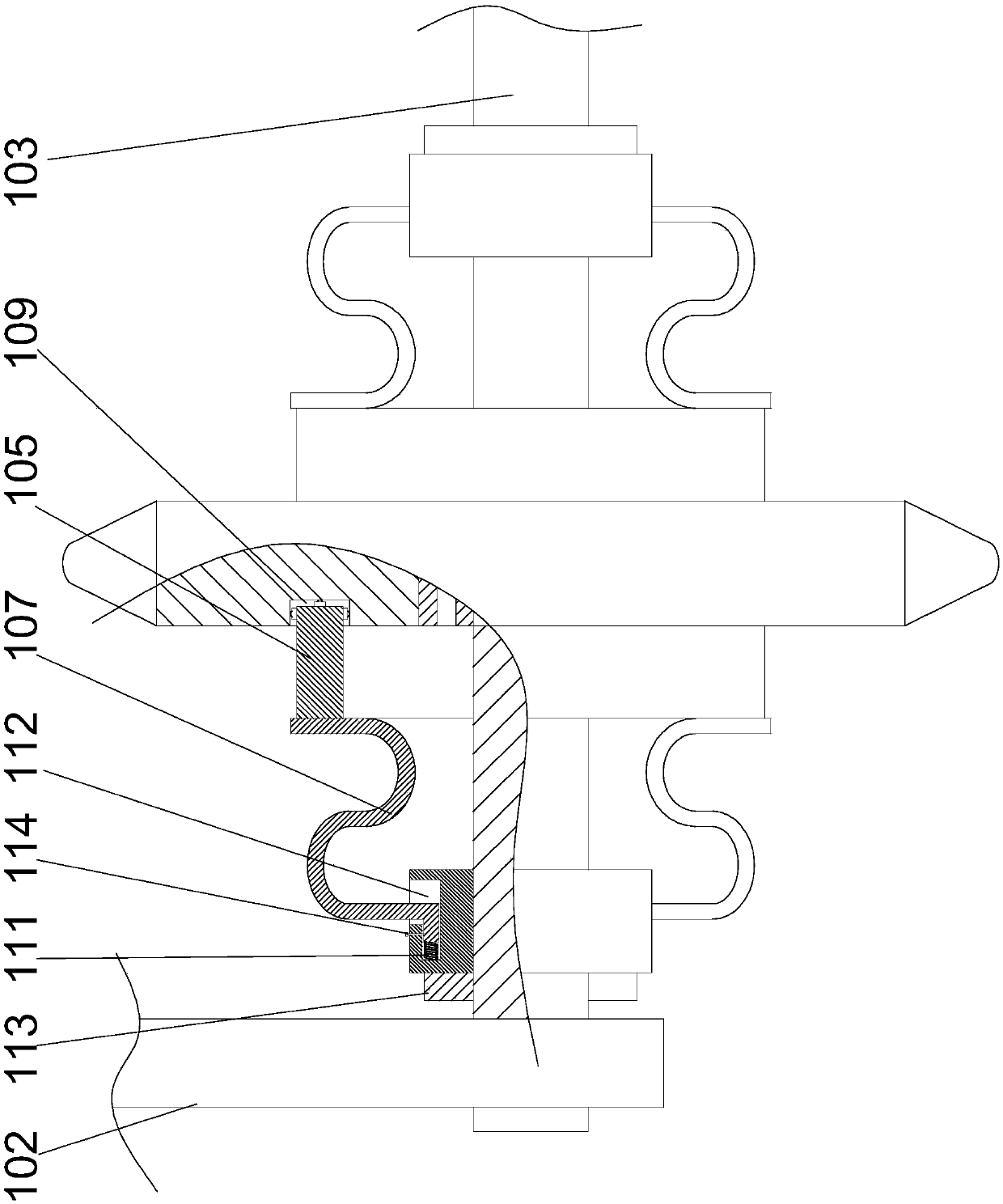

[0029] In this embodiment, in order to facilitate the installation of the legs, preferably, the outer wall of the outer tube 106 is provided with a fixing groove 112 with an L-shaped longitudinal section, and the ends of the legs 107 are L-shaped and can be plugged into The inner side of the fixing groove 112 . The fixing groove can be an annular groove centered on the axis of the outer tube. When installing, one end of the leg is fixed on the sleeve, and the other end of the leg is plugged into the fixing groove, which can facilitate the installation and disassembly of the leg. At the same time, it can Easy to adjust the outer tube.

[0030]In order to adjust the position of the outer tube according to needs, in this embodiment, preferably, the outer tube 106 is screwed on the central axis 103, and on the side of the outer tube 106 away from the support foot 107 A locking nut 113 is arranged on the central shaft 103 . After the position of the disc is determined, the outer ...

Embodiment 3

[0032] In this embodiment, on the basis of Embodiment 2, in order to improve the stability of the feet, preferably, a threaded hole communicating with the fixing groove 112 is provided on the outer wall of the outer tube 106, and in the threaded hole A locking bolt 114 is provided, and a strip-shaped counterbore is provided on the support foot 107 , and the end of the locking bolt 114 abuts against the counterbore on the support foot 107 . During installation, after inserting the end of the leg into the fixing groove, tighten the locking bolt into the threaded hole on the outer tube. At this time, when the end of the lock nut is inserted into the counterbore on the leg, the leg cannot Move axially along the outer tube. The length direction of the counterbore can be parallel to the width direction of the support foot, and the strip-shaped counterbore can facilitate the positioning of the locking bolt. The end of the support leg is fixed by the locking bolt, which can prevent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com