Novel self-closing liquidometer

A liquid level gauge and self-closing technology, which is applied in the field of new self-closing liquid level gauges, can solve the problems of large usage and inconvenient operation, and achieve the effects of high degree of generalization, small appearance and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

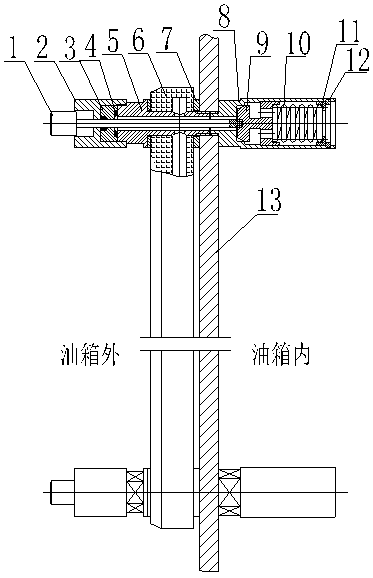

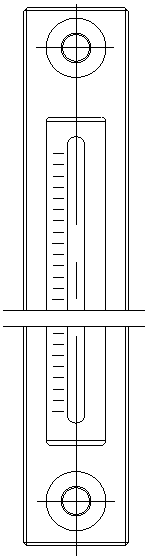

[0021] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0022] Such as figure 1 and figure 2 As shown, the liquid level gauge is refitted on the basis of the original YWZ type liquid level gauge as a whole, so as to improve standardization and facilitate manufacturing. The liquid level gauge housing 6 adopts the original liquid level gauge housing, and all other parts are redesigned and manufactured. The liquid level measurement assembly has two groups of upper and lower, both of which are fixed through the M10 threaded holes on the tank wall 13. The liquid level measurement assembly is composed of a push rod 1, a sleeve 2, a hollow bolt 5, a combination pad 7 and a valve sleeve 8, The liquid level gauge housin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com