Lamp protection device and display screen

A technology of protection device and display screen, applied in the field of display screen, can solve the problem of lamp beads falling off due to impact, and achieve the effect of avoiding falling off, good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

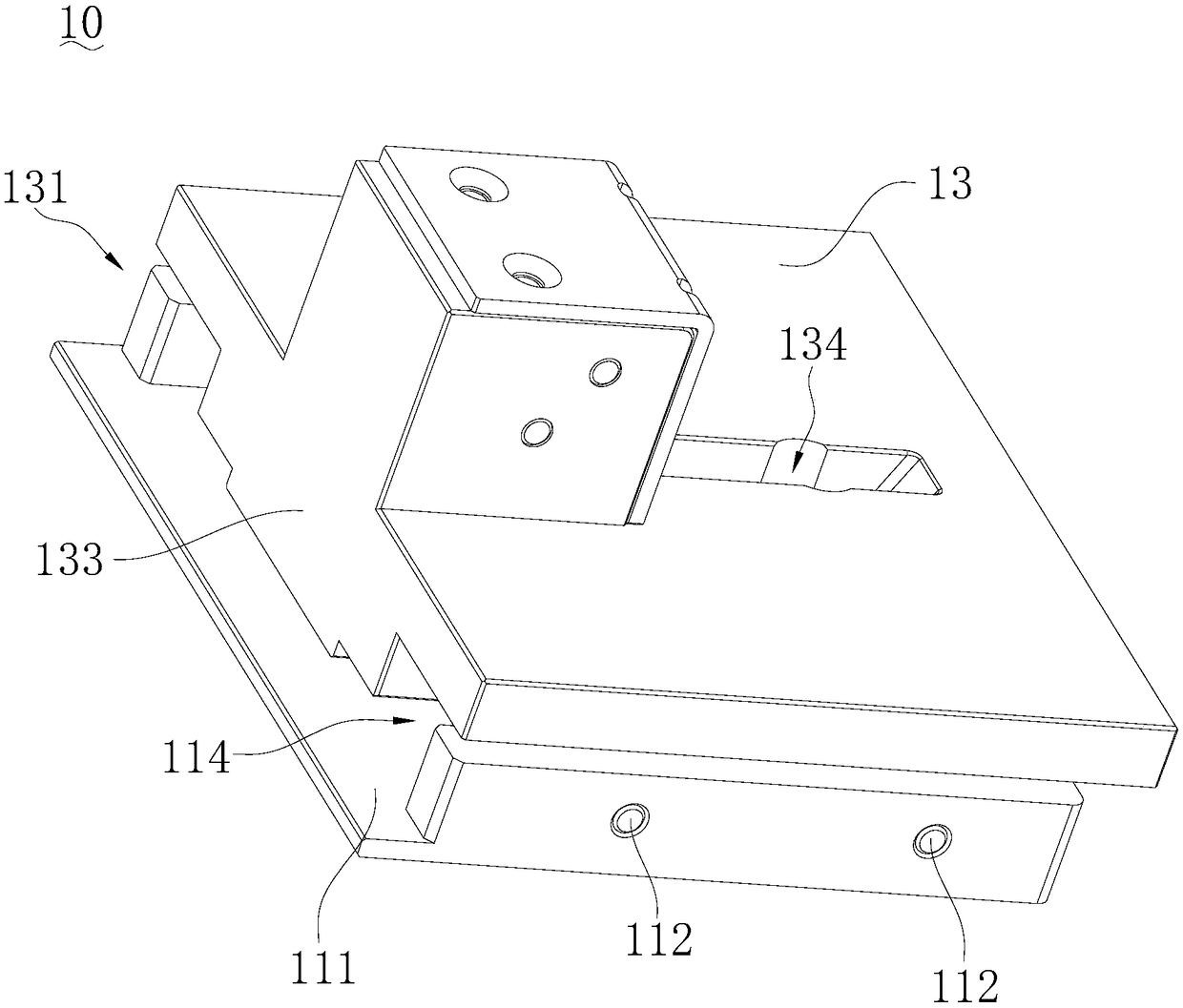

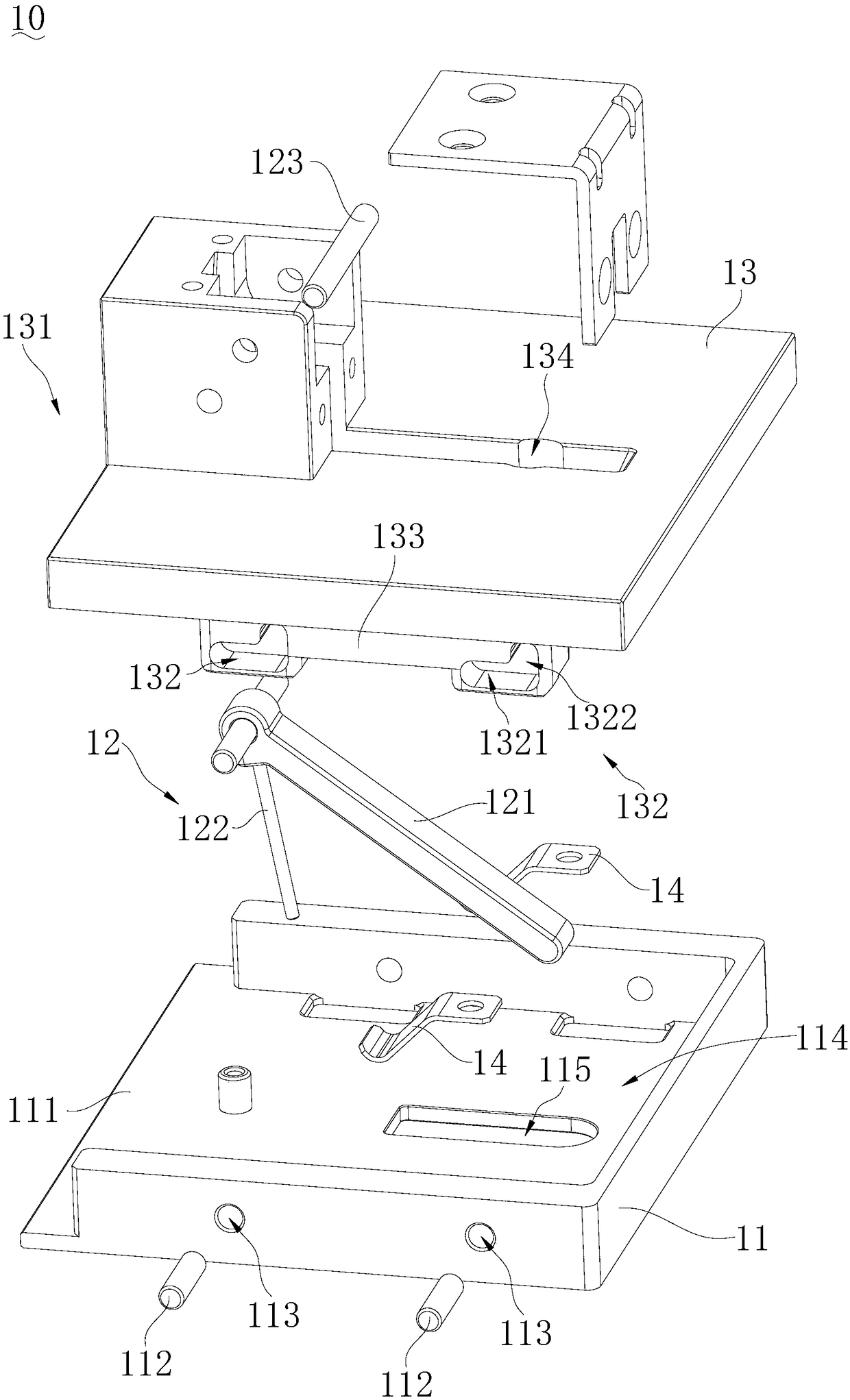

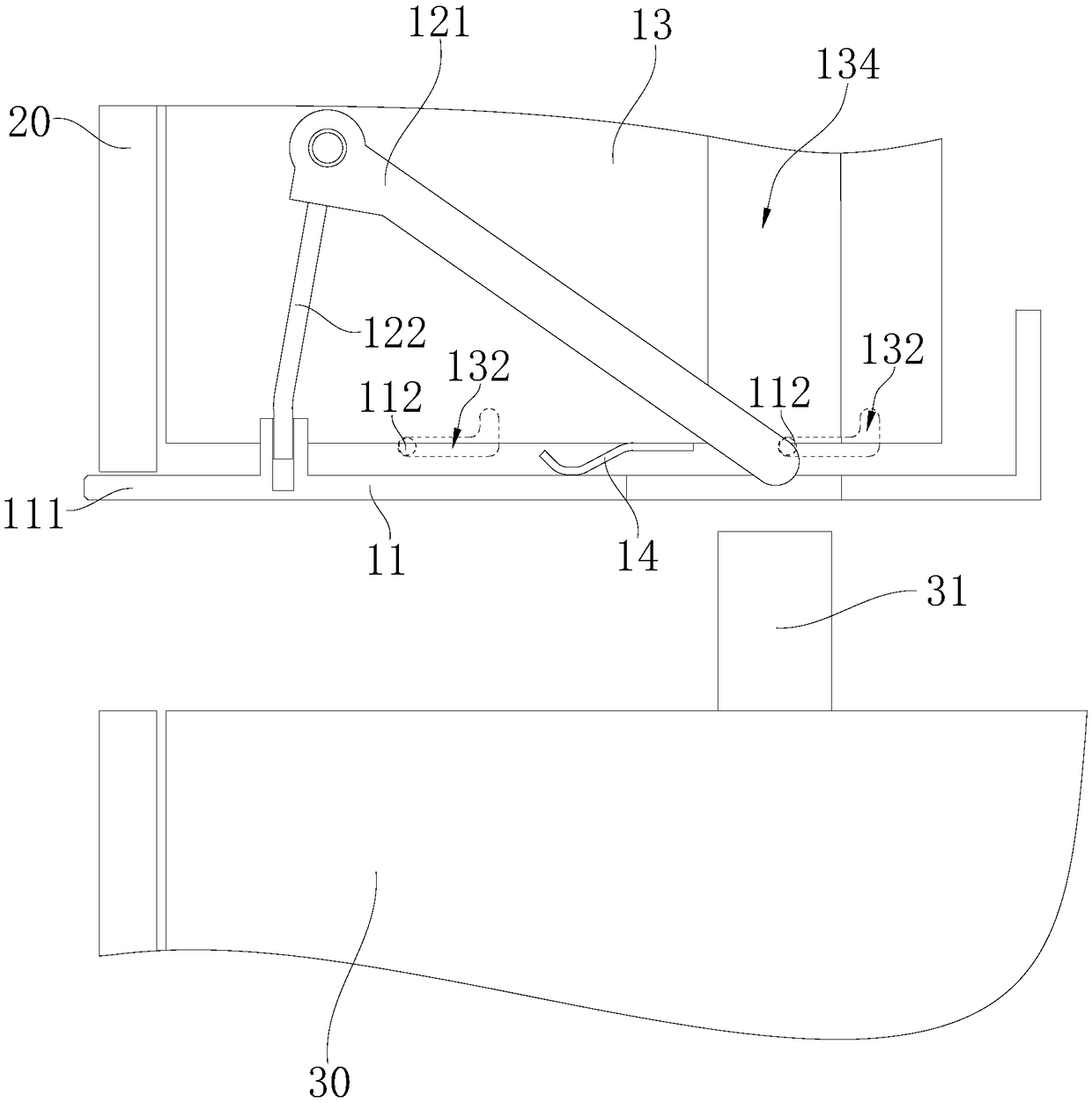

[0032] Such as Figure 1-8 As shown, the embodiment of the present invention provides a light protection device 10, which includes a protective cover 11, a driving mechanism 12 and a mounting part 13. One side of the mounting part 13 is provided with a display screen position 131, and the protective cover 11 is provided with On the side of the mounting part 13 adjacent to the display screen position 131, and the side of the protective cover 11 is provided with a protection protrusion 111 extending to the side of the display screen position 131; the driving mechanism 12 is installed on the mounting part 13, the driving mechanism 12 is connected with the protective cover 11 for driving the protective cover 11 to move, and there is a device between the protective cover 11 and the mounting part 13 The limiting mechanism is used to guide the protective cover 11 to move in a direction parallel to the bottom surface of the protective cover 11 and facing away from the protective protr...

Embodiment 2

[0059] The difference between this embodiment and Embodiment 1 is that the driving mechanism in this embodiment includes a driving rod and a connecting piece, the driving rod includes a fixed end and a free end oppositely arranged, the fixed end of the driving rod is hinged to the mounting part, and the connecting part is Vertically arranged, the upper end of the connecting piece is fixedly connected with the driving rod, the lower end of the connecting piece is hinged with the protective cover 11, and the free end of the moving driving rod drives the driving rod to rotate and then drives the protective cover 11 to move through the connecting piece. Specifically, the fixed end of the driving rod is hinged on the mounting part 13, and the upper end of the connecting part is fixedly connected to the driving rod, and the lower end of the elastic part is fixedly connected to the protective cover 11. By rotating the second end of the driving rod, the connecting part rotates, Then dr...

Embodiment 3

[0062] The difference between this embodiment and Embodiment 1 is that the driving mechanism in this embodiment includes a connecting rod and a running wheel, the running wheel is rotatably connected to the mounting part, one end of the connecting rod is hinged to the running wheel, and the other end of the connecting rod is connected to the protective The cover 11 is hinged so that the driving wheel rotates to drive the protective cover 11 to move through the connecting rod. Specifically, the running wheel is hinged on the mounting part 13, and the two ends of the connecting rod are respectively hinged on the running wheel and the protective cover 11. By turning the running wheel, the connecting rod is driven to move, and then the protective cover 11 is driven to move along a direction parallel to the protective cover. The bottom surface of the cover 11 moves in a direction away from the protection protrusion 111 in a straight line.

[0063] The rest of this embodiment is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com