Section aluminum induction pipe bending device

A technology of pipe bending device and aluminum profile, applied in the field of aluminum profile induction pipe bending device, can solve the problems of laborious operation of manual pipe bending device, complicated structure of automatic pipe bending device, inaccurate bending, etc. The determination of the radian is clear and the combination is simple.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

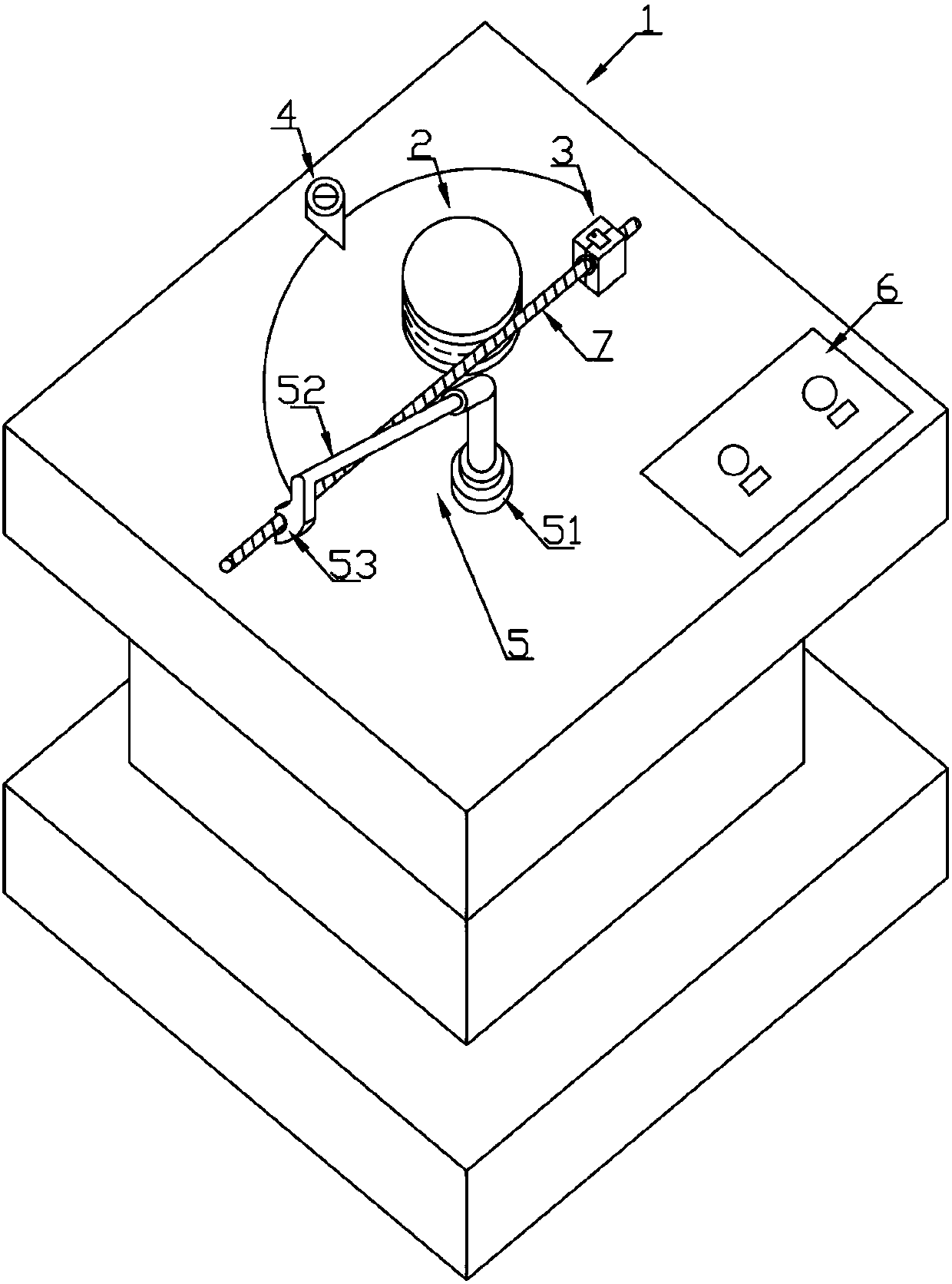

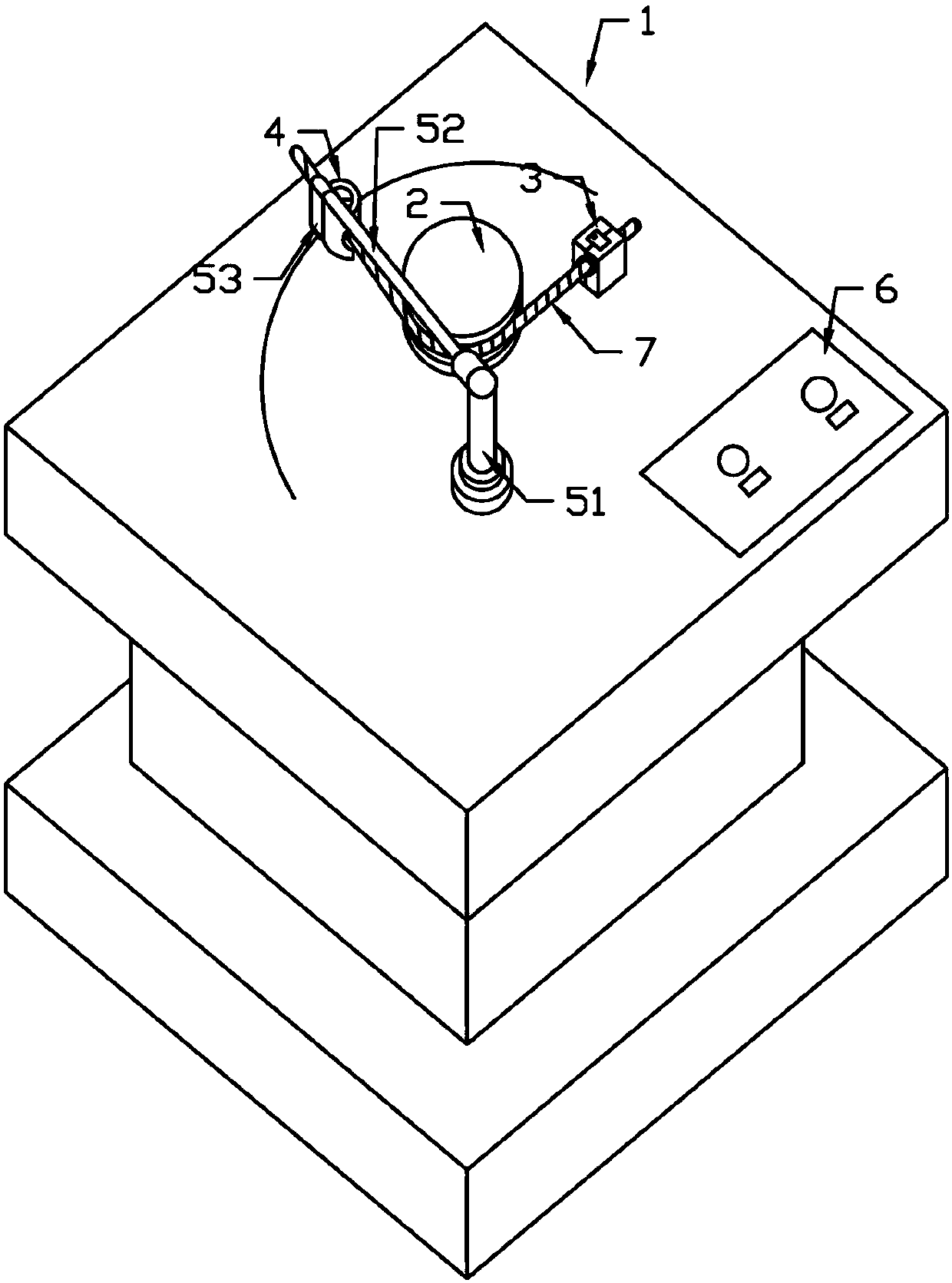

[0027] Such as figure 1 As shown, an embodiment of the present invention provides an aluminum profile 7 induction pipe bending device, including: a machine 1, a fixed wheel 2, a clamp 3, a limiter 4, a bender 5, and a control board 6. The fixed wheel 2, fixture 3, limiter 4, and bender 5 are all arranged on the top of the machine table 1.

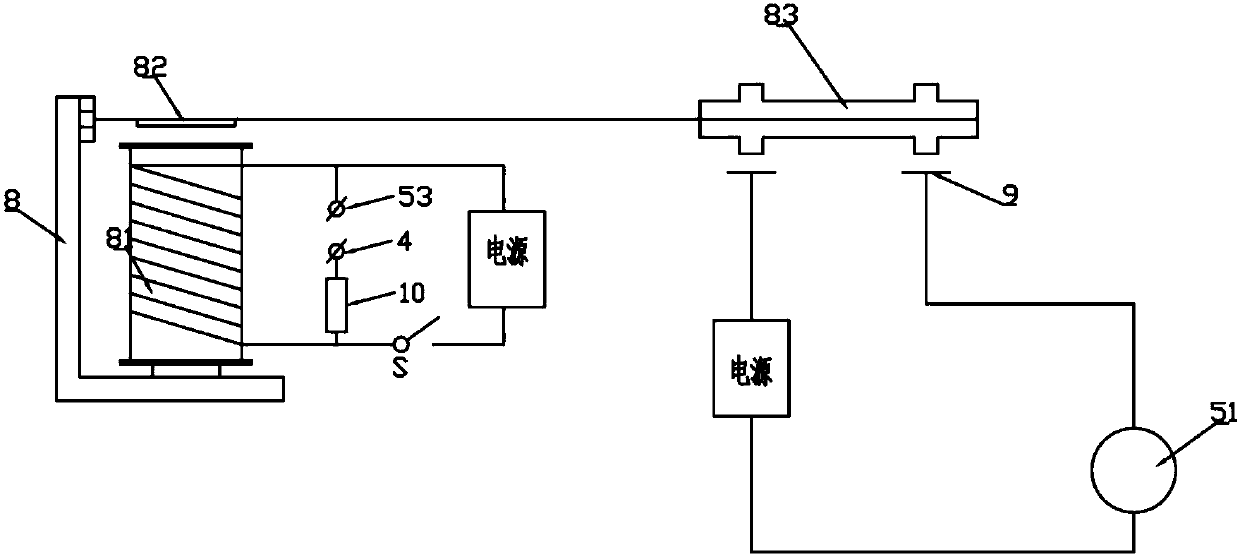

[0028] The bender 5 includes: a power drive device 51 and a bending drive arm 52; one end of the bending drive arm 52 is connected to the power drive device 51, and the other end extends vertically downward to provide a snap-in opening 53 for engaging and Push the aluminum profile 7, and at the same time, the inner wall of the locking opening 53 is provided with an electrode one.

[0029] Further, the clamp 3 is used to fix one end of the aluminum profile 7, and the aluminum profile 7 is fixed by the clamp 3 and is tangent to the fixed wheel 2, and there is a tangent point; move the center of the fixed wheel 2 toward The direction of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com