Edge-folding assembly, bending device and bending method

A bending device and component technology, applied in the direction of battery assembly, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of easily damaged aluminum-plastic film, etc., to achieve clear creases, stable bending action, and Accurate effect of scar position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

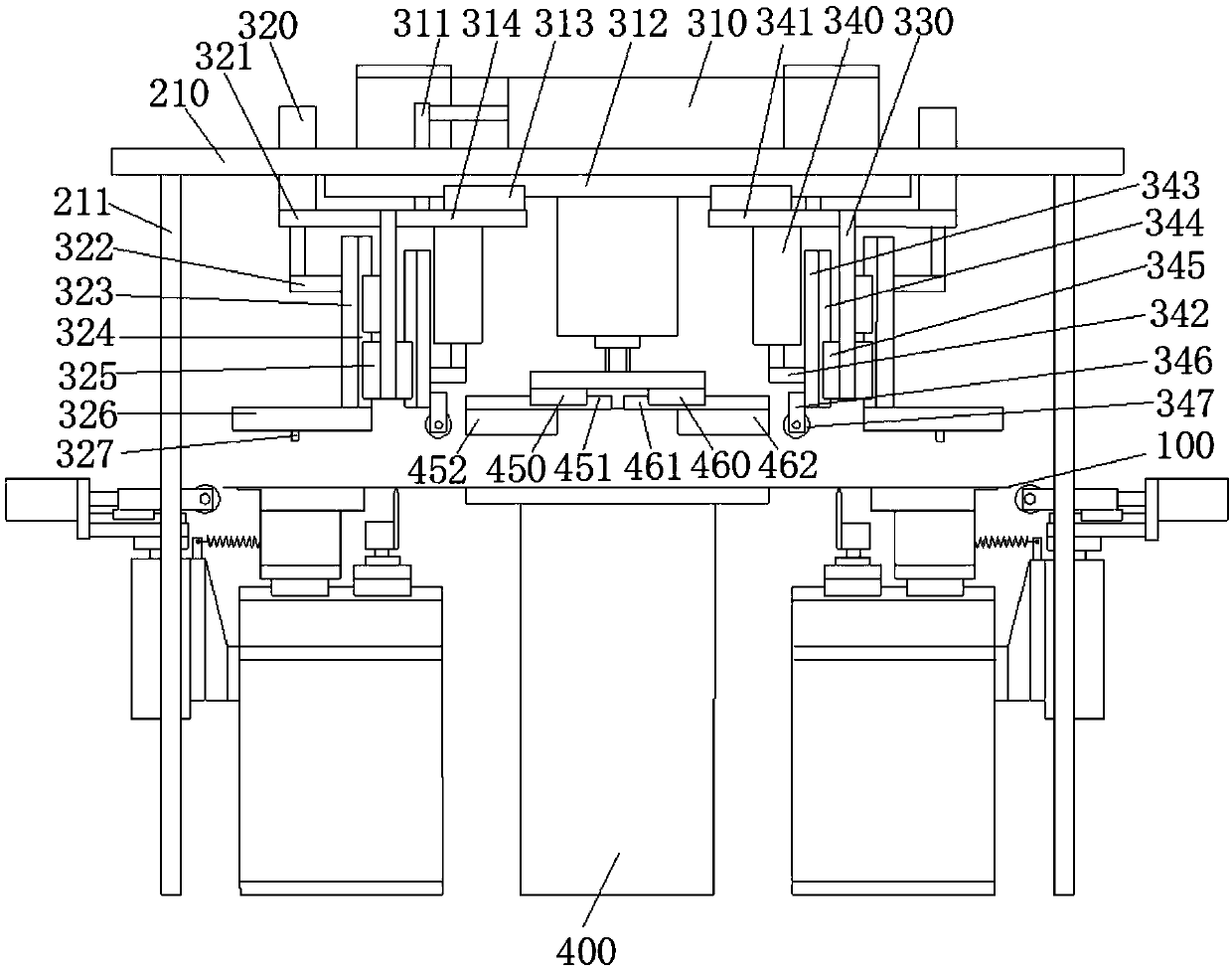

[0036] The present invention will be further described below in conjunction with specific drawings.

[0037] Coordinate references in the description of the following specific embodiments: with figure 2 The left and right direction of the paper is left and right, the up and down direction is up and down, the vertical paper surface outward is front, and vice versa is back.

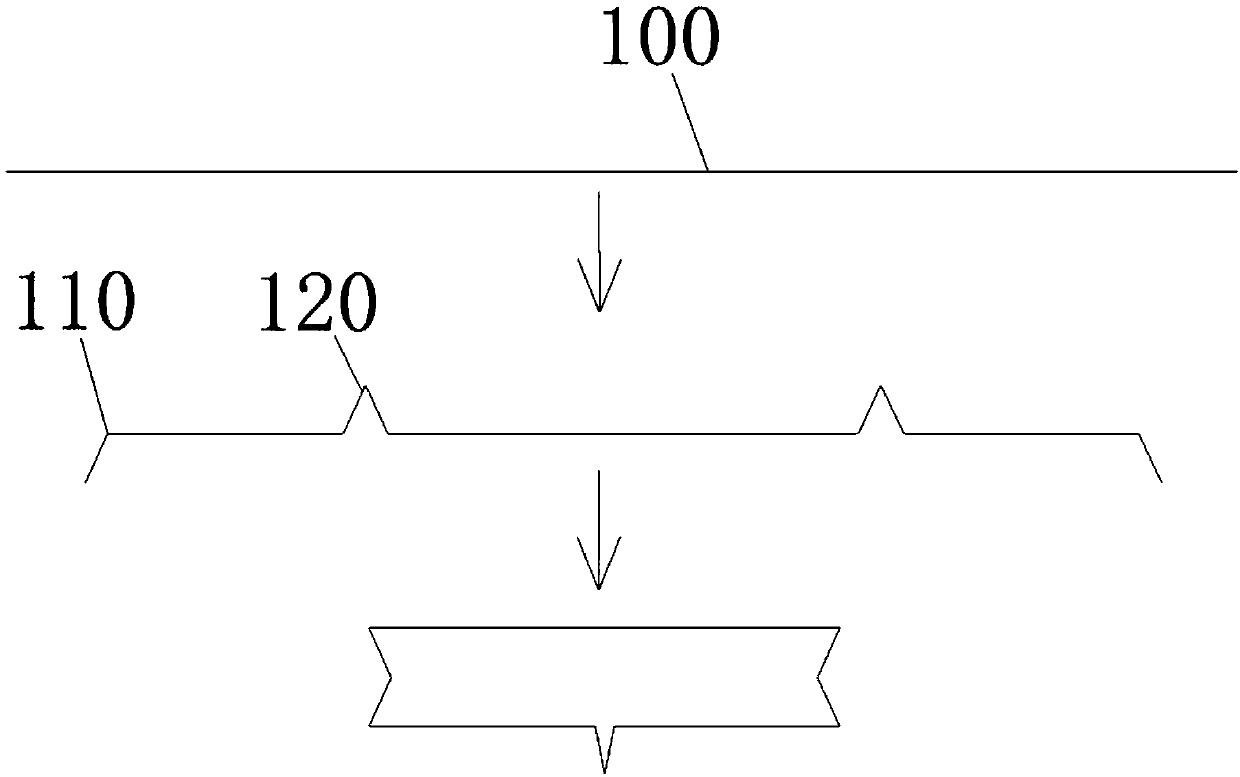

[0038] Such as figure 1 As shown, in the initial state, the material sheet 100 is a plane; after being folded by the bending device of the present invention, the two edge positions of the material sheet 100 are bent downward to form the first crease 110; the middle of the material sheet 100 is The position is arched upwards to form a second crease 120, the second crease 120 is a V-shaped crease, the opening of the V-shaped crease faces downward, and has three creases, two of which are located at the V-shaped head and the other is located at the V-shaped roots. After the material sheet 100 is folded, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com