Cargo and oil compartment hatch cover

A technology for oil tanks and cargo tanks, applied in ship hatches/hatches, ship parts, ships, etc., can solve problems such as easy deformation, affecting service life and safety, poor pressure resistance, etc., to achieve accurate tightness, Easy to operate and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

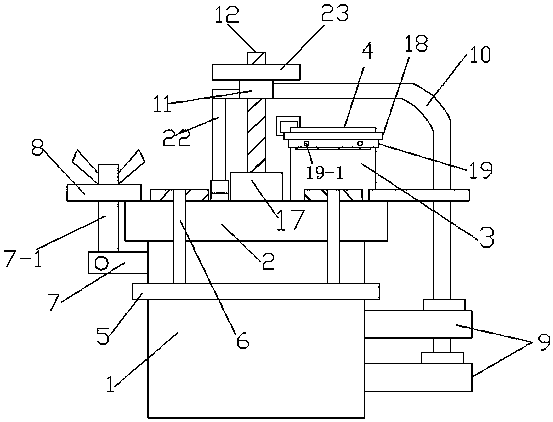

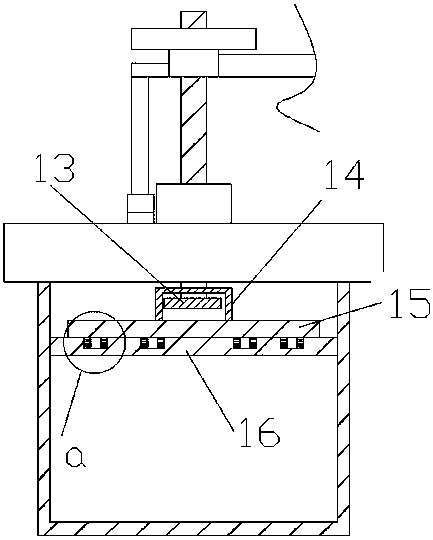

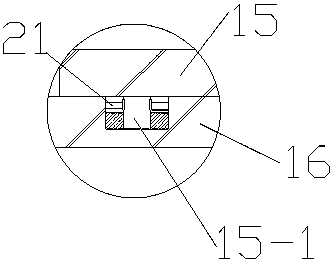

[0018] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0019] Such as Figure 1-5 Shown: a kind of cargo / oil hatch cover of this embodiment, comprises cargo tank coaming 1, cargo tank cover 2, oil tank coaming 3 and oil tank cover 4 arranged in sequence from bottom to top; The lower end of the cover plate 4 is provided with a hoop 18, and the lower end of the hoop 18 is rotated to be provided with a clamping ring 19, and the locking member 19-1 passes through the clamping ring 19 and is locked on the oil tank coaming 3 superior. The bonding force between the oil tank cover plate 4 and the oil tank coaming 3 is improved through the hoop 18, and when it needs to be opened, the locking part 19-1 is released, and the clamping ring can be turned to open.

[0020] The outer peripheral surface of the cargo hold coaming 1 is provided with a tightening ring 5, wherein the top end of the spring clip 6 is clamped and fixed wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com