Sealing structure for overhauling hole of garbage hanging and grabbing bucket

A technology of sealing structure and manhole, applied in trash cans, garbage collection, household appliances, etc., can solve problems such as odor and toxic gas leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

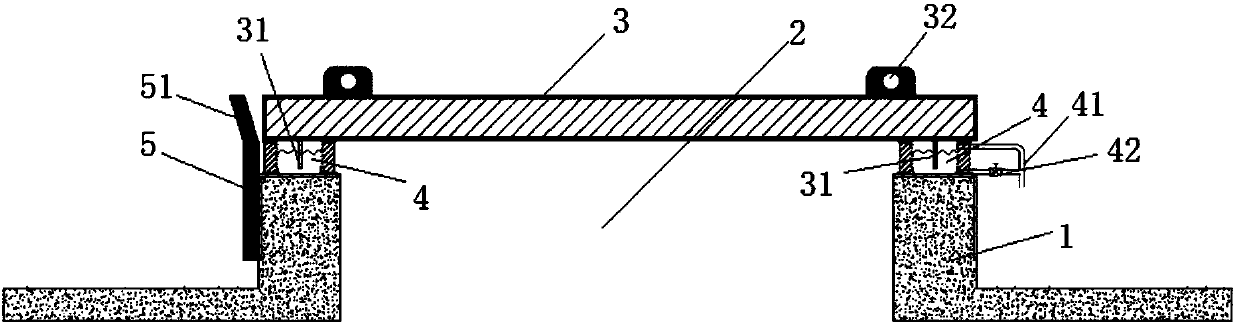

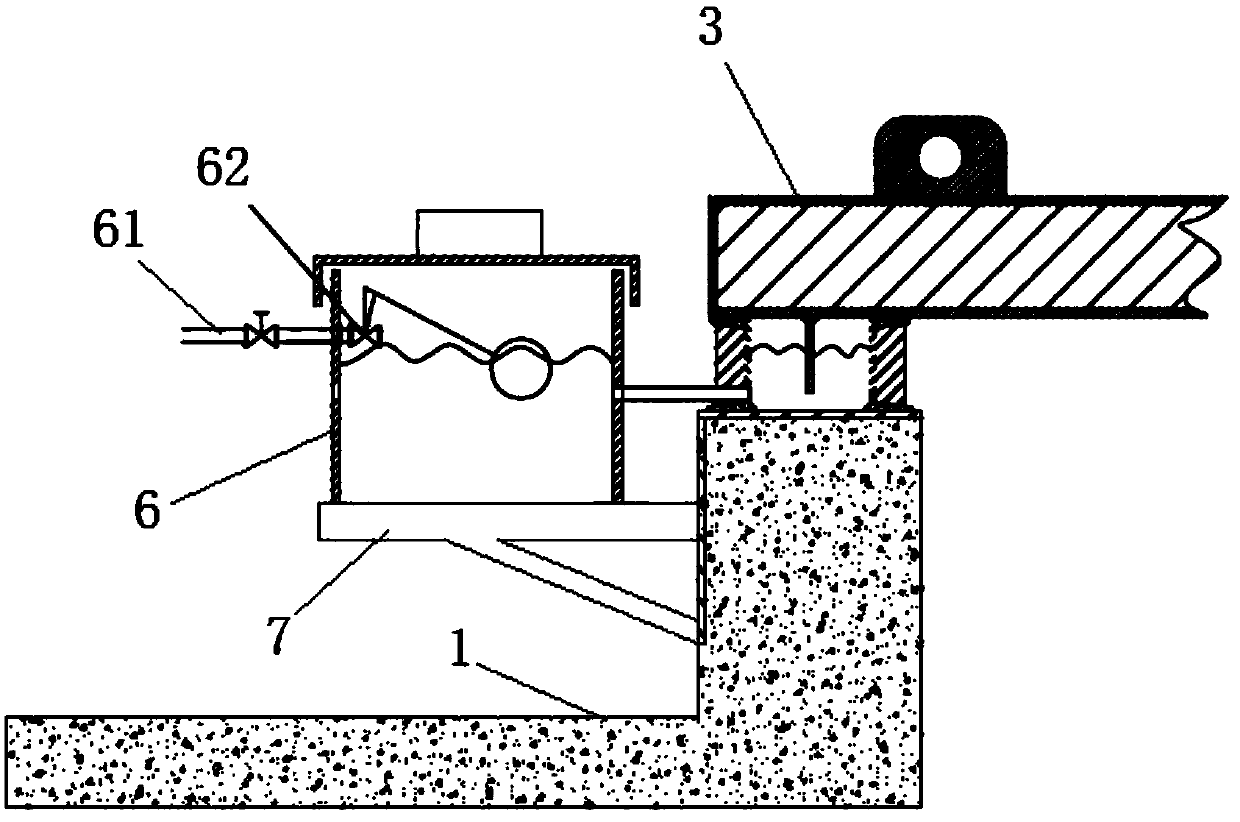

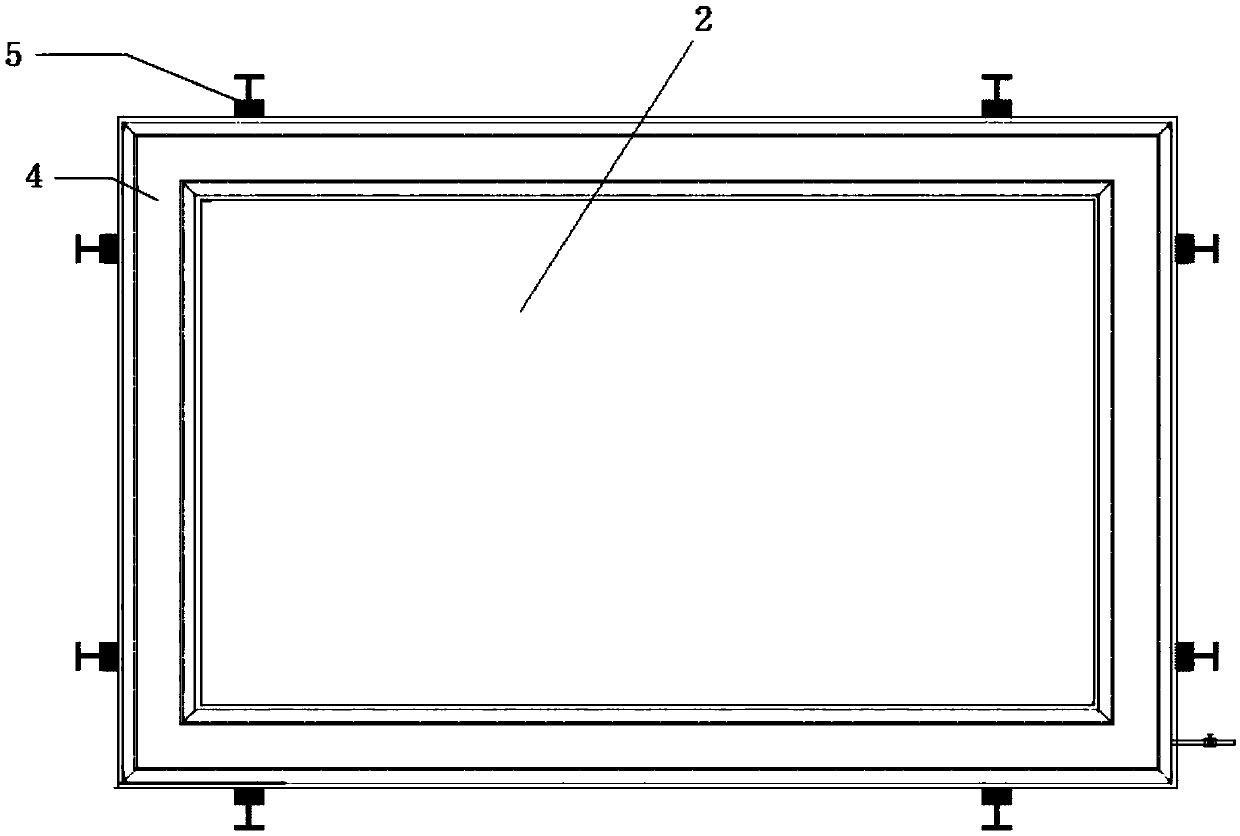

[0016] Such as Figure 1 to Figure 3 As shown, the present invention discloses a sealing structure for the overhaul hole of a garbage crane grab, including an overhaul platform 1, an overhaul hole 2 provided on the overhaul platform 1, and a cover plate 3 capable of covering the overhaul hole 2. A water storage tank 4 is provided between the cover plate 3 and the overhaul platform 1, and the water storage tank 4 is filled with water. The lower end of the cover plate 3 is provided with a water seal plate 31. The water seal plate 31 and the cover The plate 3 is vertical and placed in the water in the water storage tank 4, so that a sealed state is formed between the cover plate 3 and the manhole 2, effectively blocking the leakage of odor and harmful gas, and the sealing effect is better.

[0017] Further, the water storage tank 4 is provided with an automatic water storage device. The automatic water storage device includes a water replenishment tank 6 and a water storage pipe 61 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com