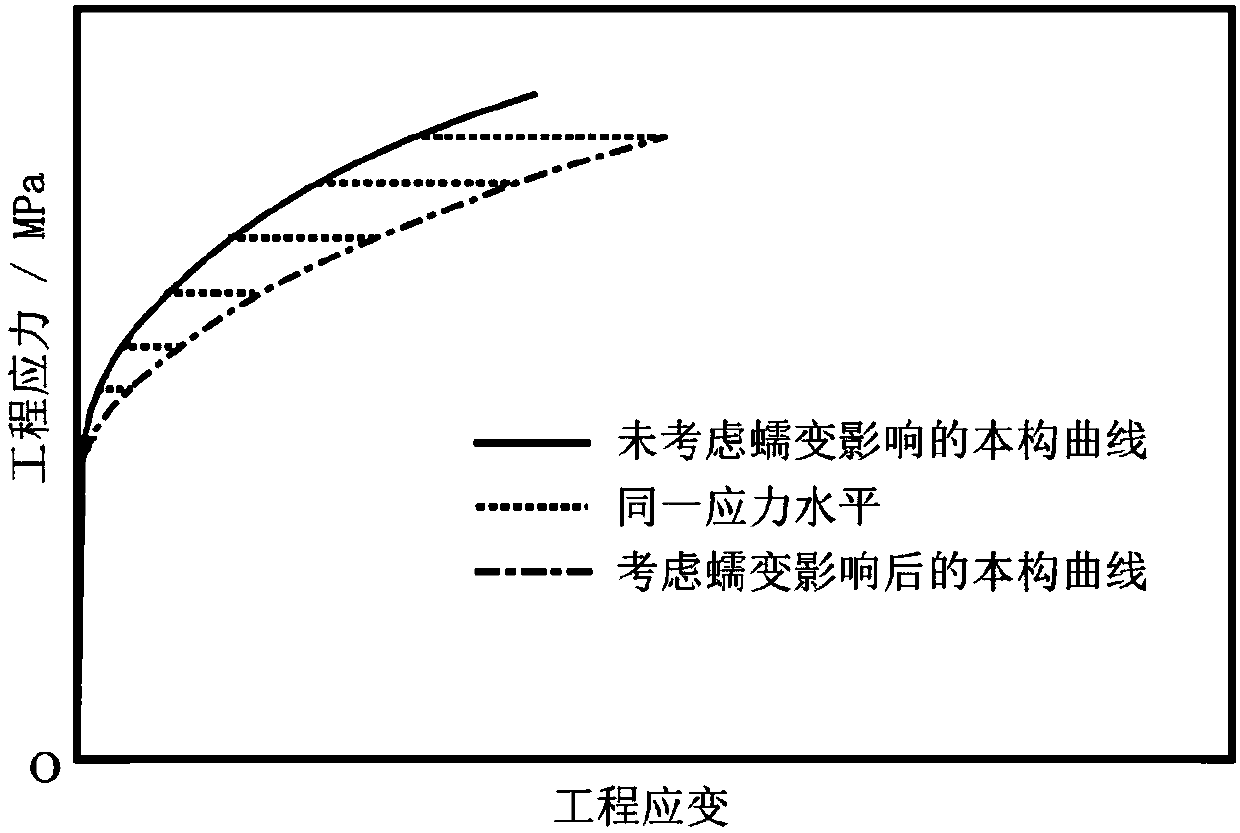

Obtaining method of austenite stainless steel constitutive curve considering room temperature creeping

A technology of austenitic stainless steel and obtaining method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., which can solve the problems of not considering the effect of room temperature creep and the calculation results not including room temperature creep and other problems , to achieve the effect of improving prediction accuracy and accurate prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with specific examples, the method for obtaining the constitutive curve of austenitic stainless steel considering room temperature creep is further described in the present invention:

[0018] (1) Obtain the original data for constructing the constitutive curve through the tensile load test of austenitic stainless steel materials:

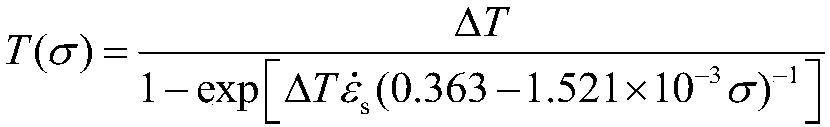

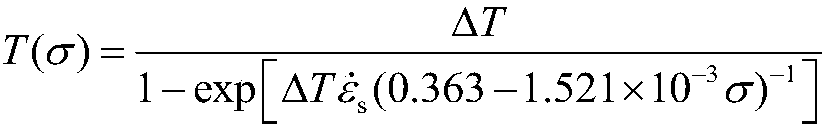

[0019] Take the austenitic stainless steel to be processed as a sample, and carry out a room temperature tensile test according to the standard GB / T 228.1-2010 "Metallic Materials Tensile Test Part 1: Room Temperature Test Method"; the test process is controlled by force, at the same rate After stretching the sample to the set stress σ, the load is maintained, and the holding time T(σ) is calculated by the following formula:

[0020]

[0021] In the above formula: It is aimed at artificially setting the expected strain rate at the end of room temperature creep, that is, when the strain rate is less than or equal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com