Automobile transmission remote monitoring and debugging system

A technology of automobile transmission and remote monitoring, applied in the direction of control/adjustment system, test/monitoring control system, general control system, etc., can solve the time-consuming and laborious maintenance process, can not meet the needs of users to quickly repair the transmission remotely, waste maintenance time and travel expenses and other problems, to achieve good working conditions, reduce commissioning time and travel costs, and optimize shifting quality and performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

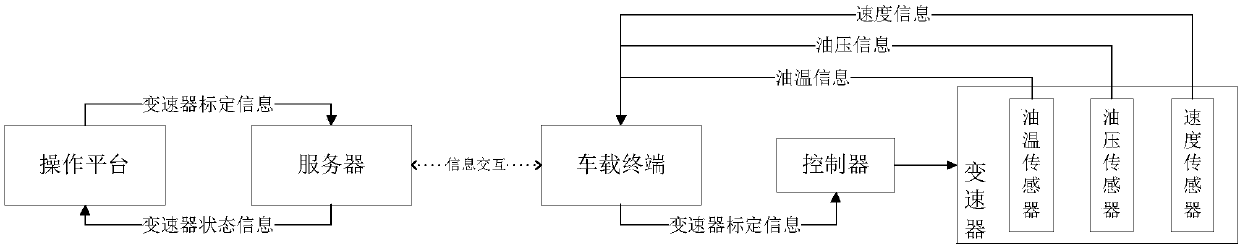

[0018] Such as figure 1 As shown, a remote monitoring and debugging system for an automobile transmission, including an operation platform, a server, a vehicle terminal, a controller and a transmission, the operation platform is connected to the server, the server is connected to the vehicle terminal, the vehicle terminal is connected to the controller, and the controller is connected to the transmission ; The transmission is connected with the controller, and the state information of the transmission is fed back to the controller when it is working.

[0019] The operation platform can be specifically a computer or a mobile phone, and relevant data information can also be sent to the user through this system, so that the user can understand the working status and working parameters of the transmission in real time. The server has c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com