On-board vertical-fin conformal omnidirectional antenna

An omnidirectional antenna and vertical tail cavity technology, which is applied in the electrical field, can solve the problems of inability to realize, the performance of the omnidirectional antenna has a great influence, and the application of the vertical tail conformal antenna is limited, and achieves stable performance, optimized aerodynamic performance, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

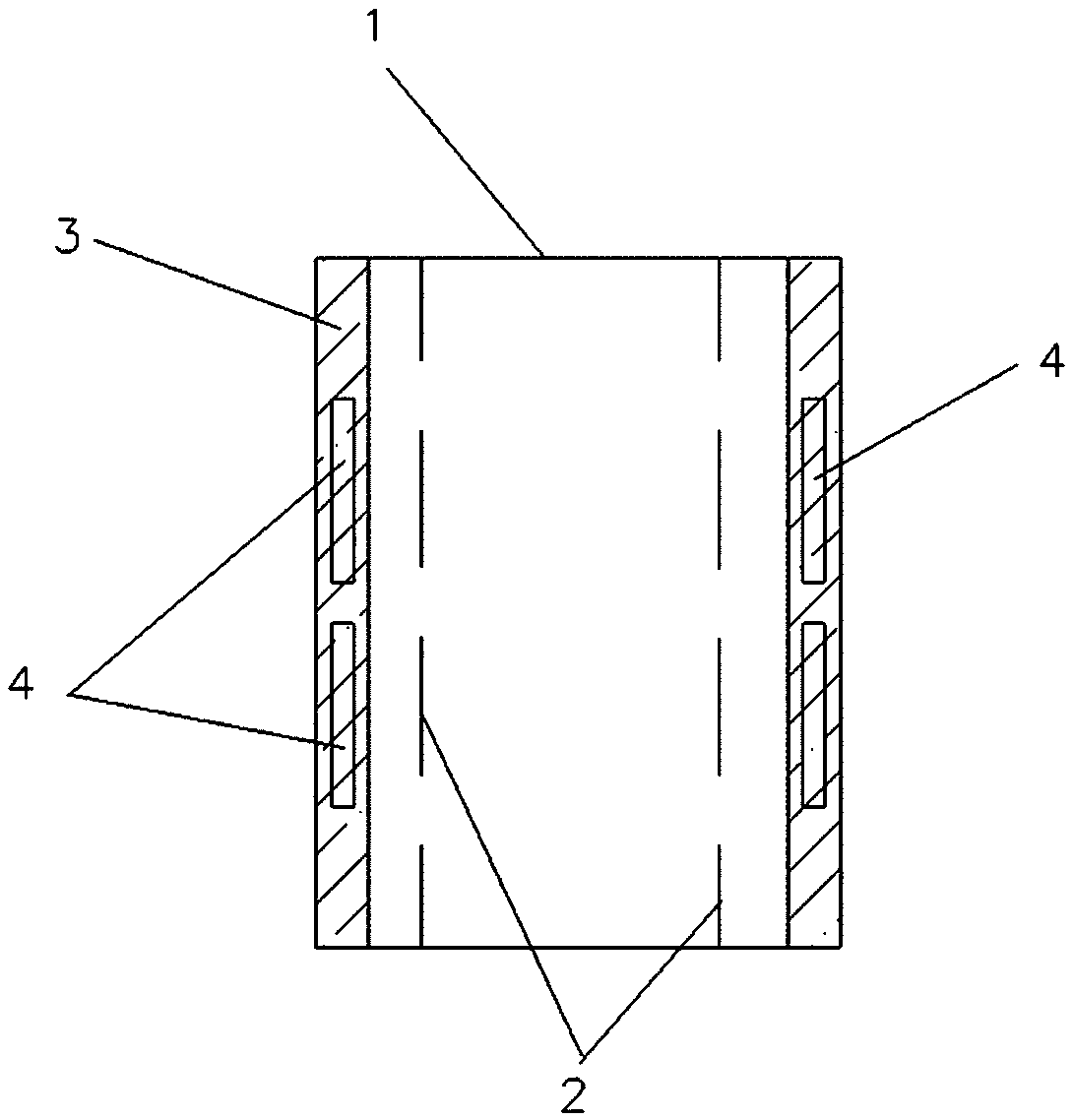

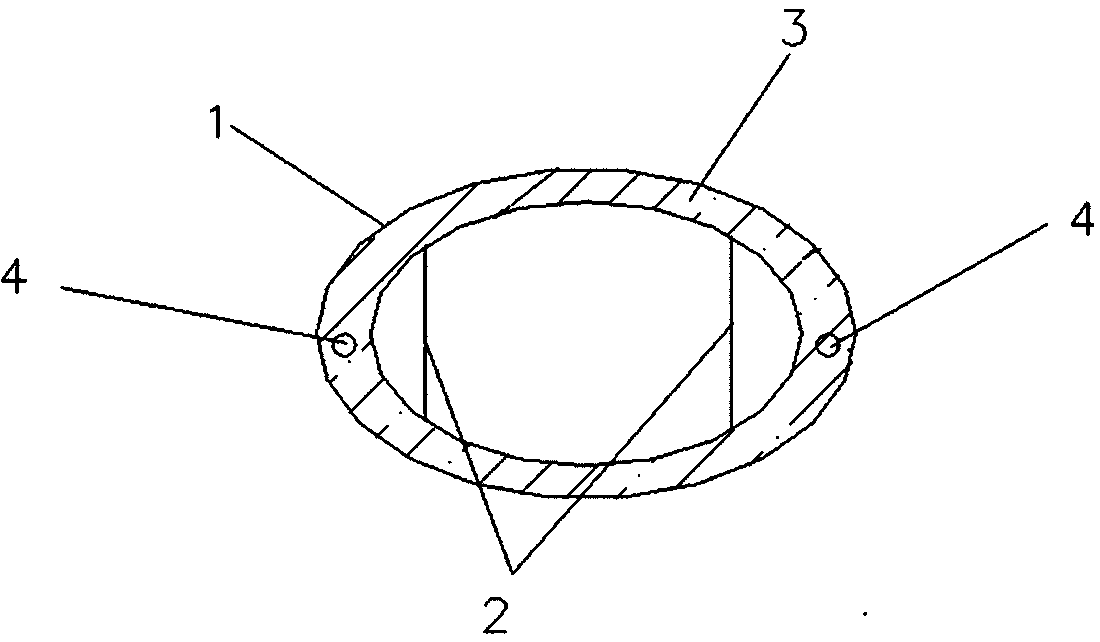

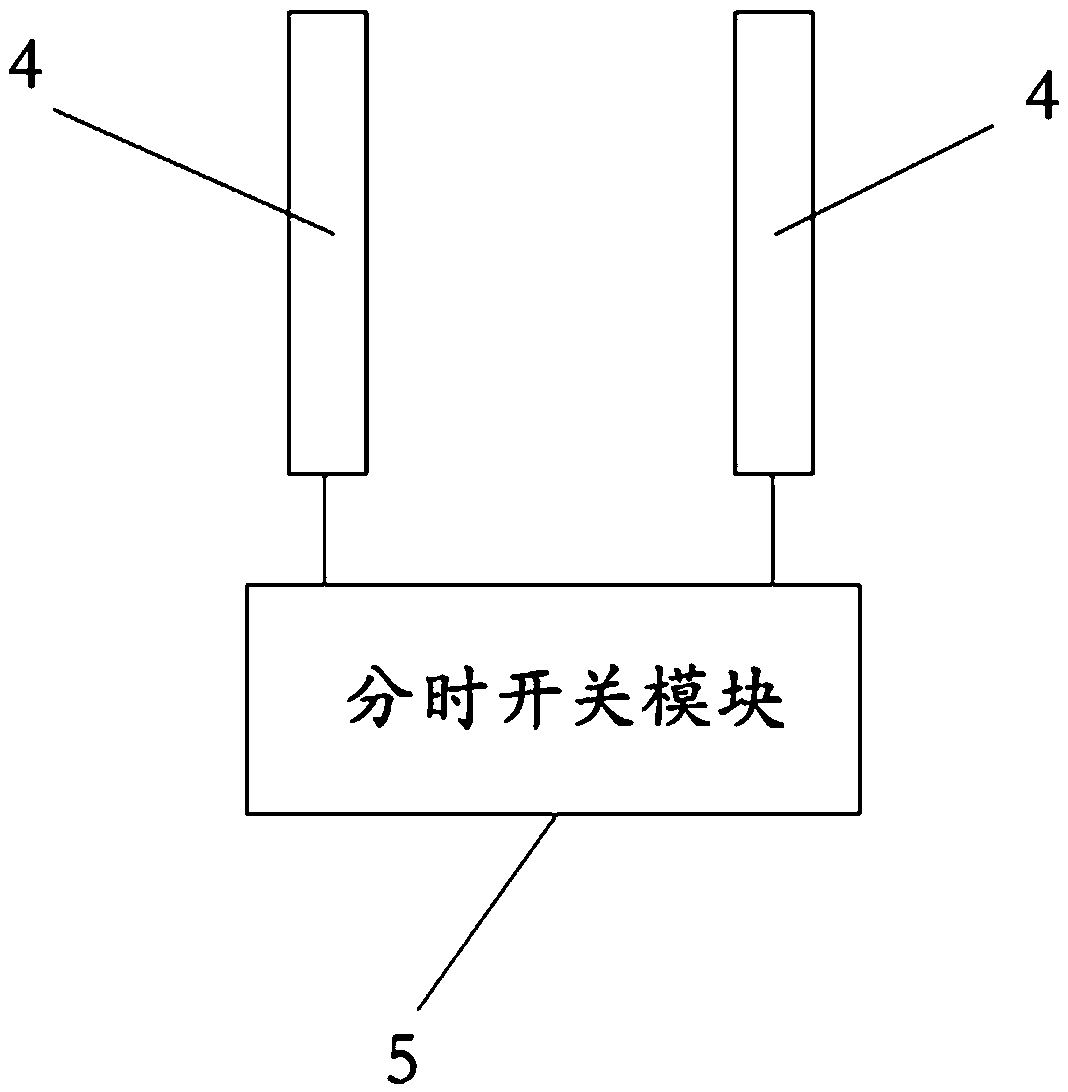

[0014] Such as Figures 1 to 3 As shown, this airborne vertical tail conformal omnidirectional antenna of the patent of the present invention includes an aircraft vertical tail 1 and an omnidirectional antenna 4, the omnidirectional antenna 4 is arranged in the surface skin 3 of the aircraft vertical tail 1, and the omnidirectional antenna 4 It is a group correspondingly arranged on both sides of the structural metal part 2 in the cavity of the vertical tail 1 of the aircraft. The omnidirectional antenna 4 is electrically connected to the time-sharing switch module 5. The time-sharing switch module 5 can produce milliseconds to nanoseconds according to the general requirements of communication. The time-sharing control signal between them is used to control the omnidirectional antenna to work alternately in time-sharing to generate a horizontal omnidirectional pattern.

[0015] Further, the omnidirectional antenna 4 and the skin 3 are integrally formed so that the omnidirectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com