Automatic cover sealing device and process method for flexible printed circuit (FPC) connector assembly equipment

A technology for assembling equipment and connectors, which is used in the assembly/disassembly, connection, circuit/collector parts and other directions of contacts, which can solve the problems of frequent safety accidents, low qualification rate and high product cost, and reduce safety. The effect of accidents, high product qualification rate and high market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

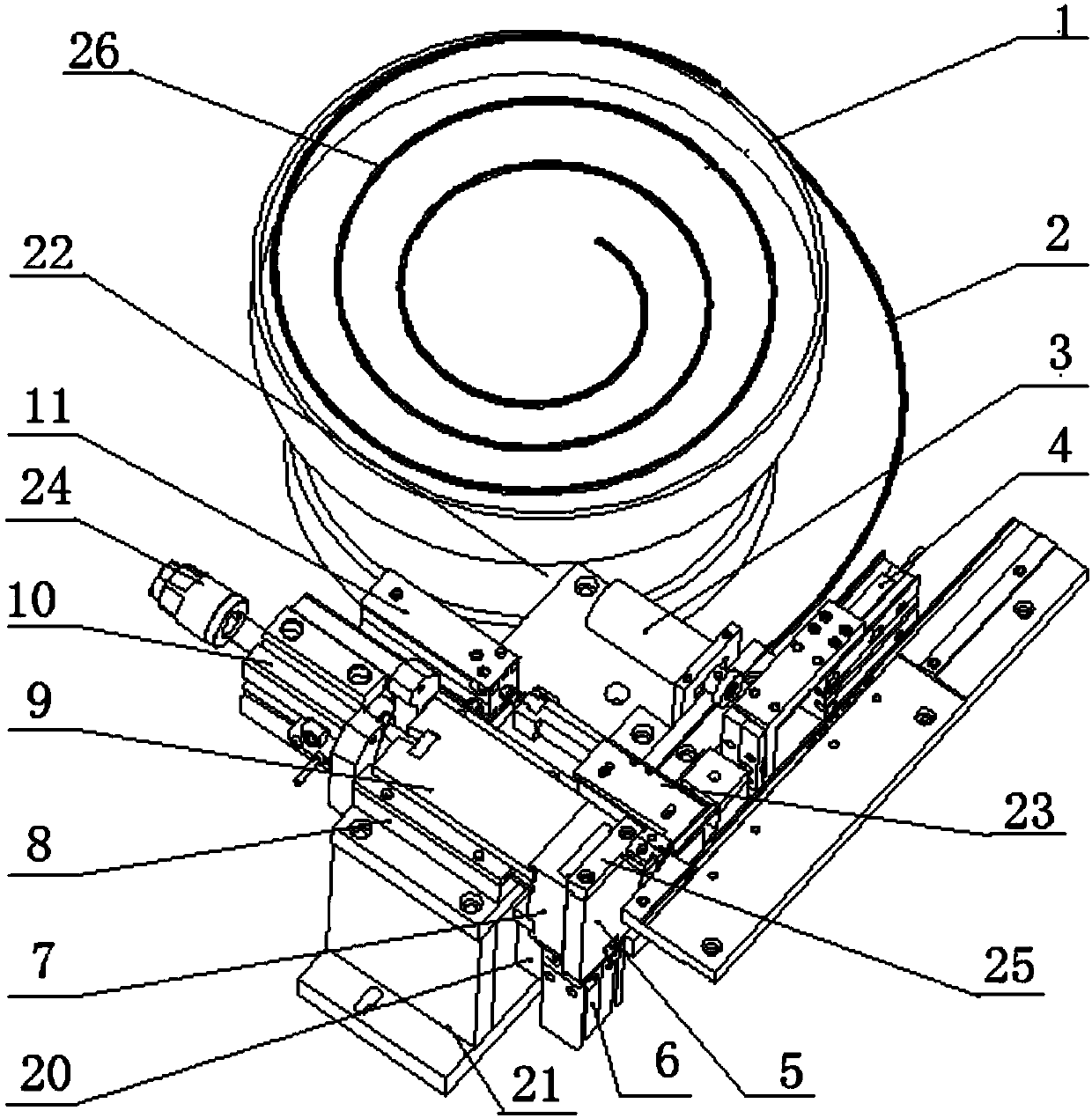

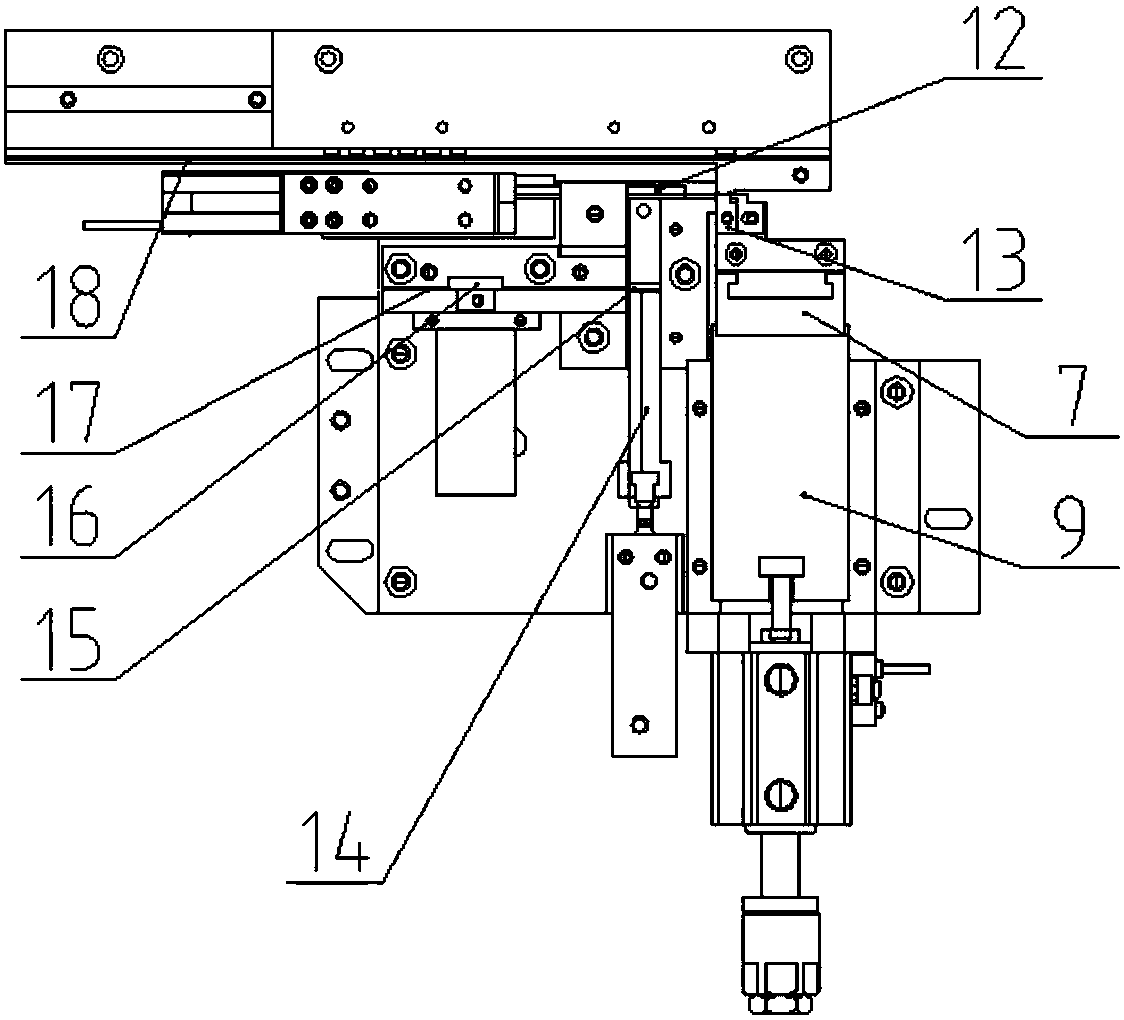

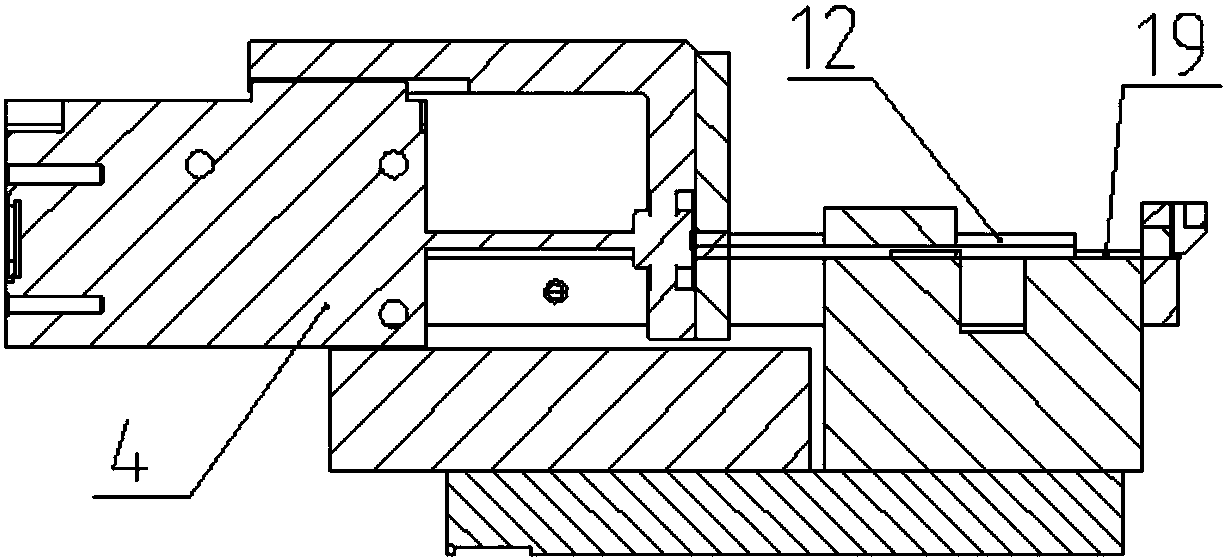

[0022] combine Figure 1-3 , the automatic capping device for FPC connector assembly equipment of the present invention, it comprises bracket base 21, and bracket base 21 is provided with cover feeding mechanism 22, cutting off pushing mechanism 23 and stroke adjustable mechanism 24, and cover feeding mechanism 22 It is connected with the cutting and pushing mechanism 23 and the adjustable stroke mechanism 24 in turn. The vertical movement mechanism 25 is arranged on the lower side of the end of the adjustable stroke mechanism 24. The adjustable stroke mechanism 24 and the vertical movement mechanism 25 are respectively connected to the assembly runner 18. In cooperation, the assembly flow channel 18 is arranged on one side of the cutting and pushing mechanism 23, and a connector is arranged in the assembly flow channel 18.

[0023] Through the feeding mechanism 22, the cutting and pushing mechanism 23, the stroke adjustable mechanism 24 and the vertical moving mechanism 25, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com