Wire winding tool for electrician operation

A wire-winding tool and a technique for operation, applied in the field of wire-winding tools for electrician operation, can solve the problems that the attached structure cannot be in close contact, the quality of operation is unfavorable, and the coil is easy to spring back and open, so as to improve the joint connection quality, Make up for the neglect of relevant details and the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with specific embodiments.

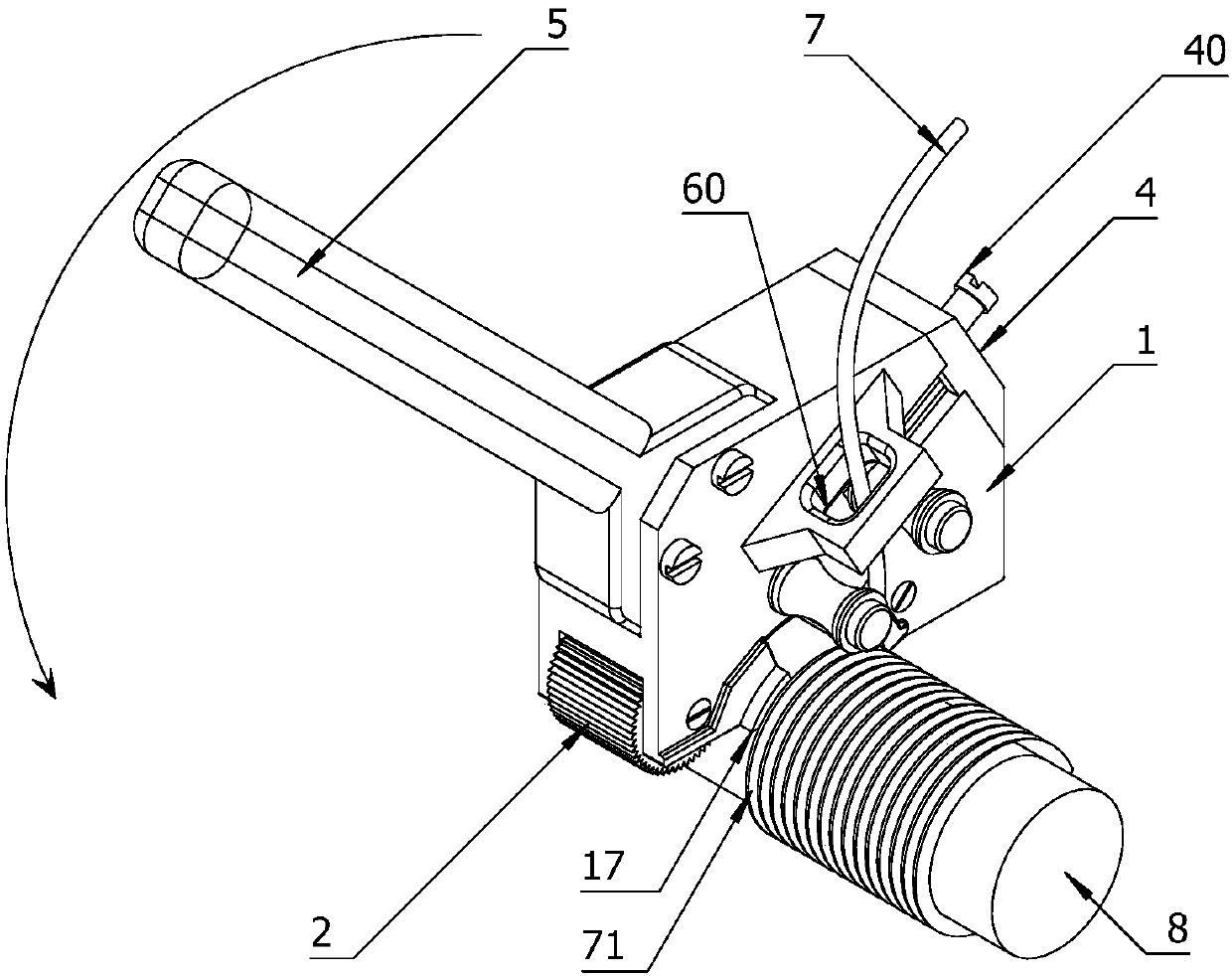

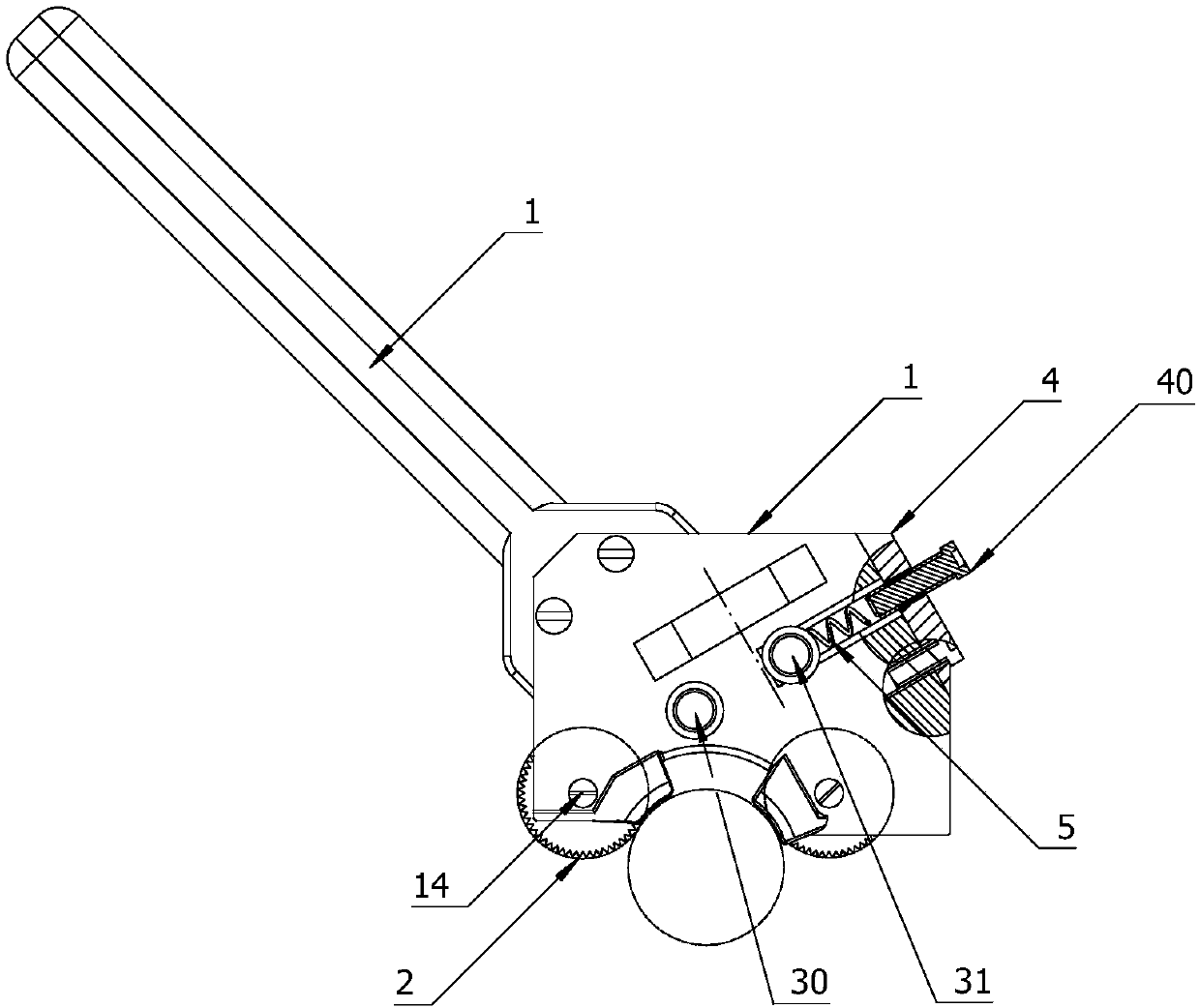

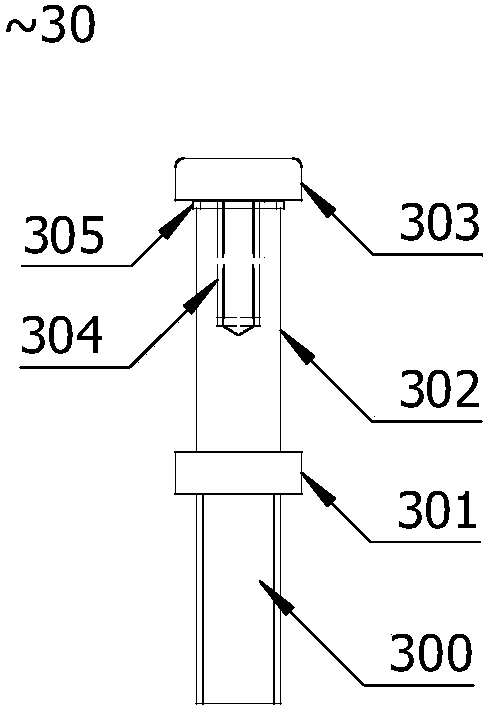

[0032] Such as figure 1 , figure 2 As shown in , a wire winding tool for electrician operation of the present invention is used to evenly wrap cables and other structures on other rod-shaped or wire-shaped structures, and its specific structure includes a support base 1 for supporting and connecting each structure , the support seat is provided with the first roller 2 and the roller column 30, 31 in sequence from bottom to top; Mounting holes 13 are respectively provided on the top and both sides of the notch 11, and a roller shaft 14 is installed in the mounting hole 13. The first roller 2 is fixed in the U-shaped groove through the roller shaft 14. Further, the middle part of the U-shaped groove 12 is also provided with Avoid space 110 to prevent friction between the edge of the roller and the support seat; the surface of the first roller 2 is provided with anti-ski...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com