Strain clamp

A technology of tension clamp and clamp plate, applied in the direction of adjusting/maintaining mechanical tension, optical fiber/cable installation, cable suspension device, etc., to achieve the effect of improving work efficiency and not easy to adjust deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

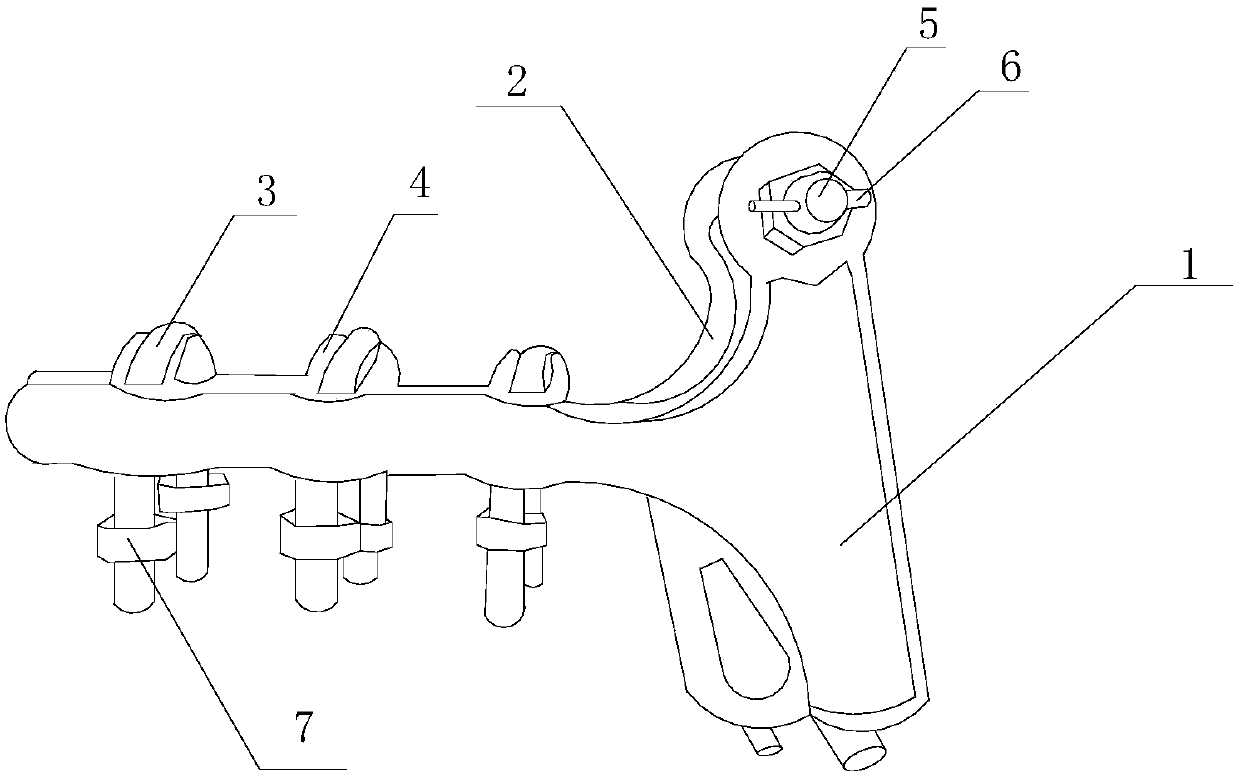

[0015] Such as figure 1 As shown, the present invention includes a strain-resistant clamp, including a first line clamping plate 1 and a second line clamping plate 2, and the first line clamping plate 1 and the second line clamping plate 2 both include horizontal plates and vertical plates. The vertical plates of the first line clamping plate 1 and the second line clamping plate 2 vertically cross the connecting rod 5, and also cross the limit rod 6 on the end face of the connecting rod 5, on the first line clamping plate 1 and the second clamping plate A plurality of limiting grooves 4 are arranged between the horizontal plates of the line plate 2, and an n-type limiting member 3 is installed in each limiting groove 4, and a bolt 7 is sleeved on the bottom of the n-type limiting member 3.

[0016] When it is necessary to fix the wires, loosen the bolts at the bottom of all n-type limiters, put the wires into the cavity formed by the first clamping plate and the second clampin...

Embodiment 2

[0018] This embodiment is preferably as follows on the basis of Embodiment 1: the bottoms of the first wire clamping plate 1 and the second wire clamping plate 2 are also provided with threading holes. Easy to carry out threading operation.

[0019] The edge portions of the vertical plates of the first line clamping plate 1 and the second line clamping plate 2 are also provided with drainage grooves. The drainage groove is used to quickly drain the rainwater that falls on it, so as to prevent the rainwater from staying on it for a long time and corroding the device.

[0020] Two guard plates for protecting the n-type limiting member 3 are arranged on each limiting groove 4 . The n-type limiter is protected inside to avoid unnecessary falling off of the n-type limiter due to external force.

[0021] Both ends of the first wire clamping plate 1 and the second wire clamping plate 2 are arranged in an arc-shaped structure. Avoid scratching other parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com