Liquid Cooling System

A heat dissipation system and liquid cooling technology, applied in cooling/ventilation/heating renovation, electrical components, electrical equipment structural parts, etc., can solve problems such as reducing heat dissipation efficiency, damage to the pump, etc. The effect of preventing the influence of heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

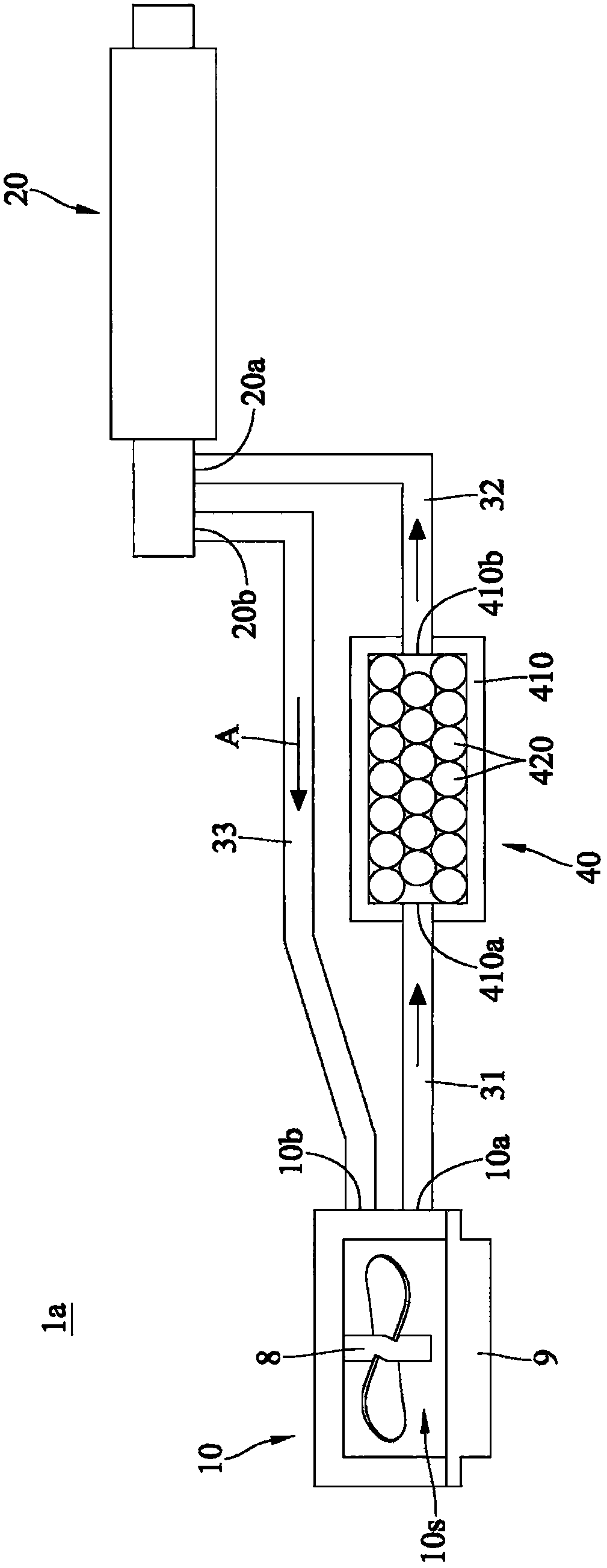

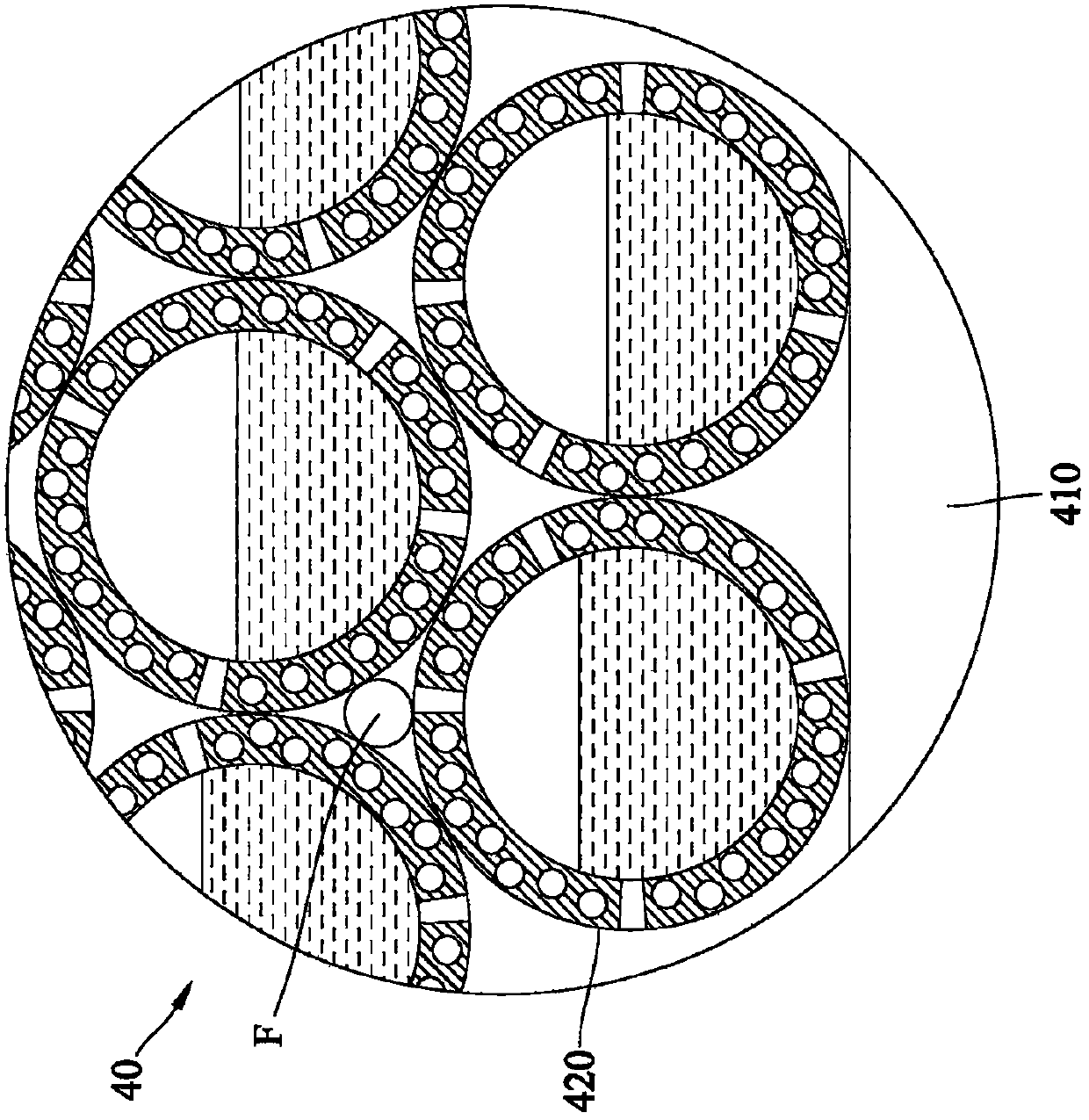

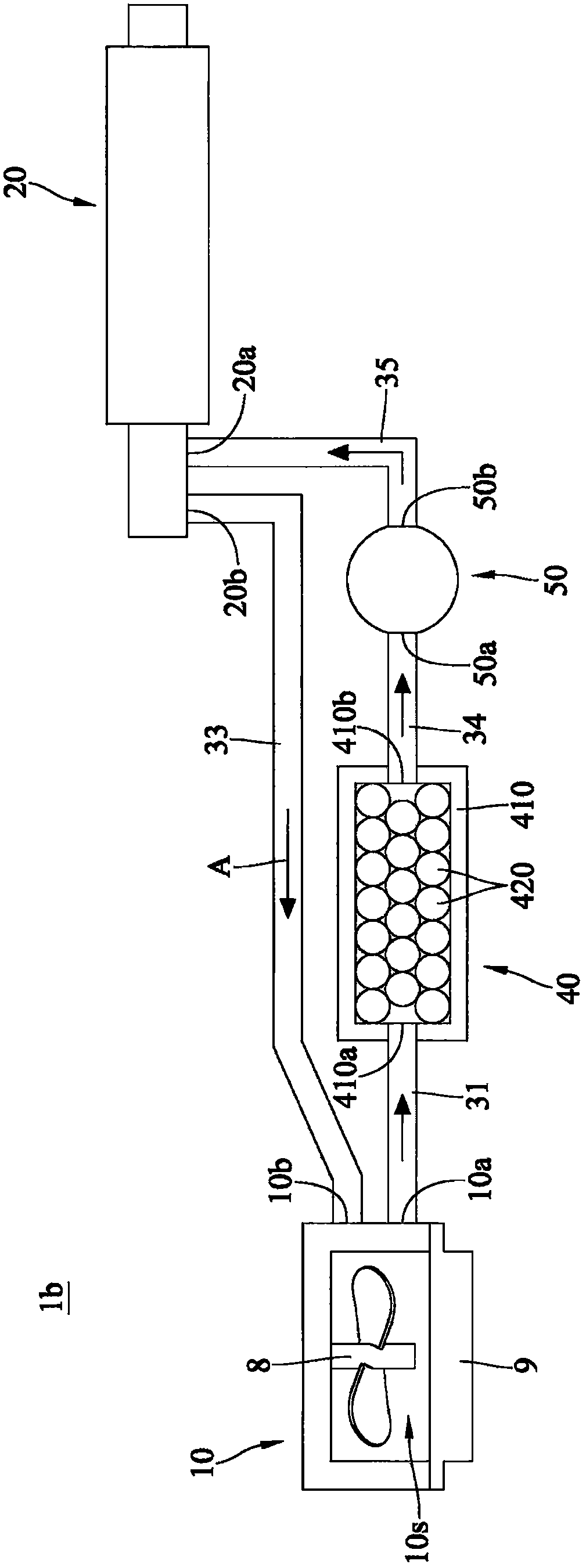

[0043] An embodiment of the present invention provides a liquid-cooled heat dissipation system, including a liquid-cooled row, a liquid-cooled head, a plurality of flow pipes, and an air adsorption device. The liquid cooling head is in thermal contact with at least one heat source. The flow pipe is connected between the liquid cooling head and the liquid cooling row to form a circuit for communicating and circulating the cooling liquid with the liquid cooling head and the liquid cooling row. The air adsorption device communicates with the circuit to absorb the air in the cooling liquid. Due to the design of the air adsorption device connected to the liquid cooling circuit, it can absorb the air entering the circuit, which not only prevents the air in the circuit from affecting the heat dissipation performance, but also maintains the smooth operation of the pump, avoiding the operation noise caused by the pump sucking in air, and more Can prolong the service life of the pump. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com