Method and device of assembling components, considering the relative spatial position ifnormation

A technology of relative space and components, applied in the direction of electrical components, electrical components, etc., can solve the problems of unfavorable and time-consuming waiting for vibration, and achieve the effect of eliminating waiting time, low cost, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

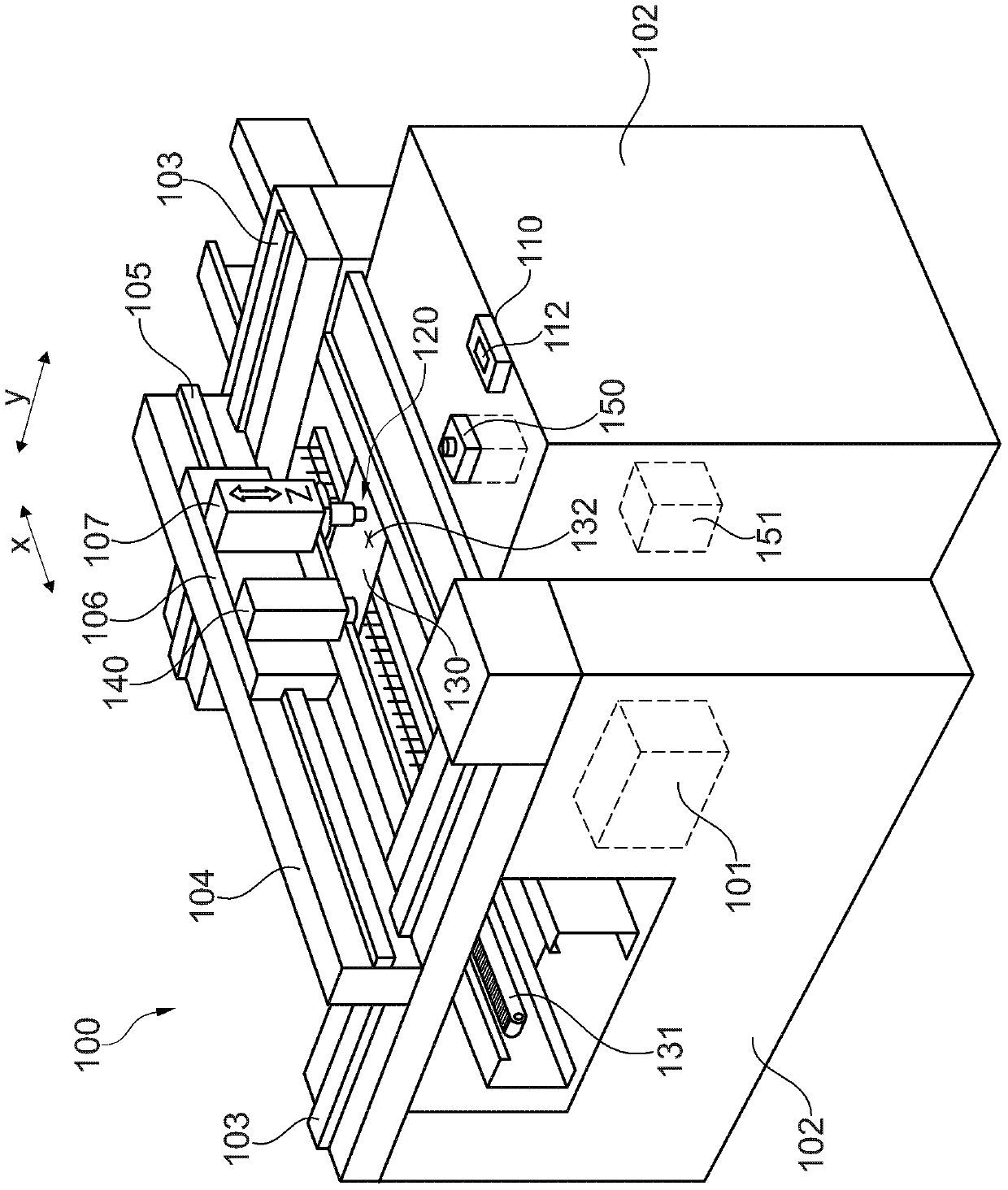

[0098] The same or similar parts are indicated by the same reference signs in the drawings.

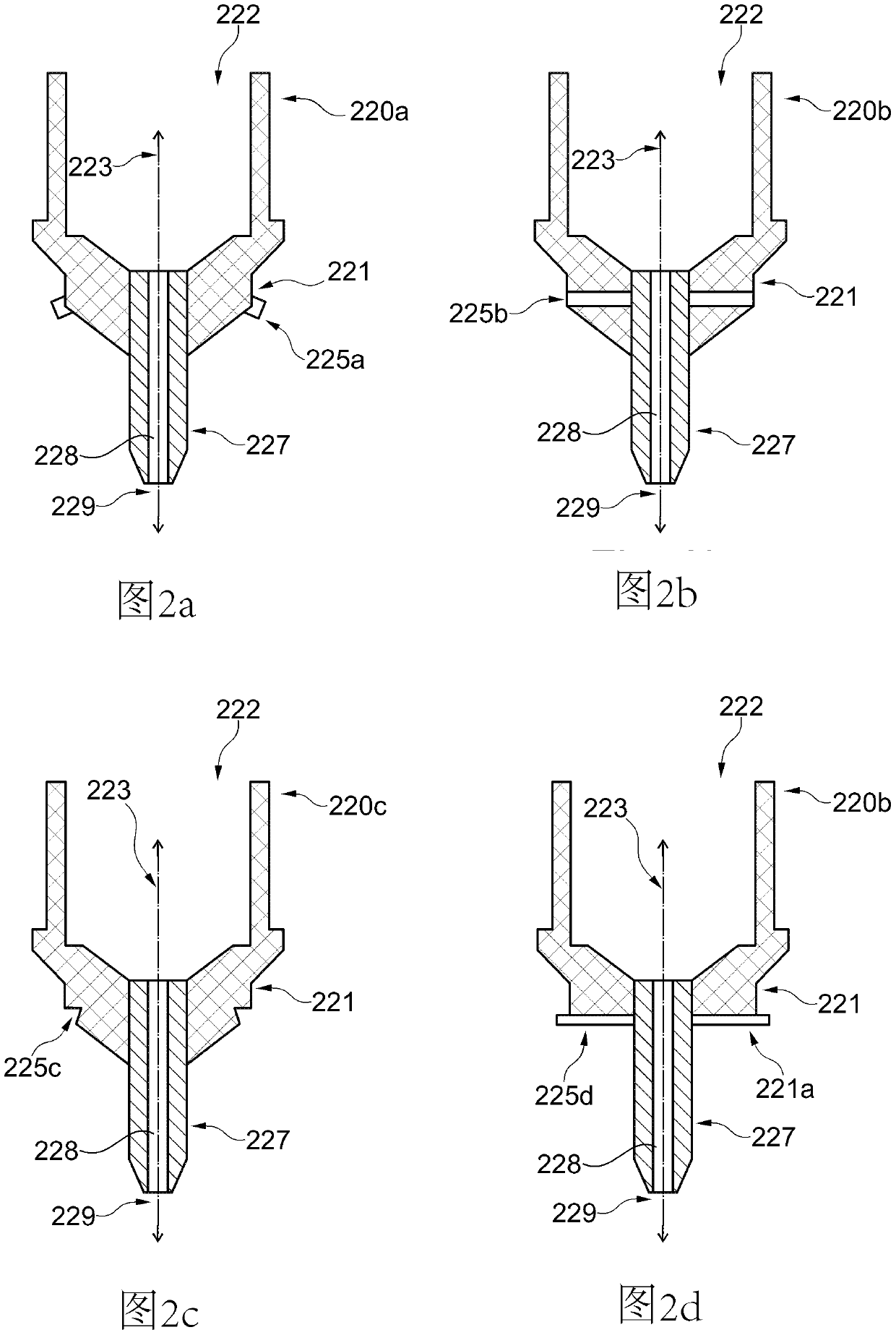

[0099] According to the embodiment, when the component is measured on-the-fly in an automatic assembly machine, the following restrictions must be overcome when applying the method: i) The measurement accuracy is affected by the difference between the camera and the component. Physical effects such as vibration; ii) Position synchronization between the driver of the assembly head and the display system (ie camera). In principle, this method can also optimize today's pick and place processes in terms of time. Because the position and angle-reference are obtained directly through the component-holding device (especially the straw), there is no need to wait for the stop time.

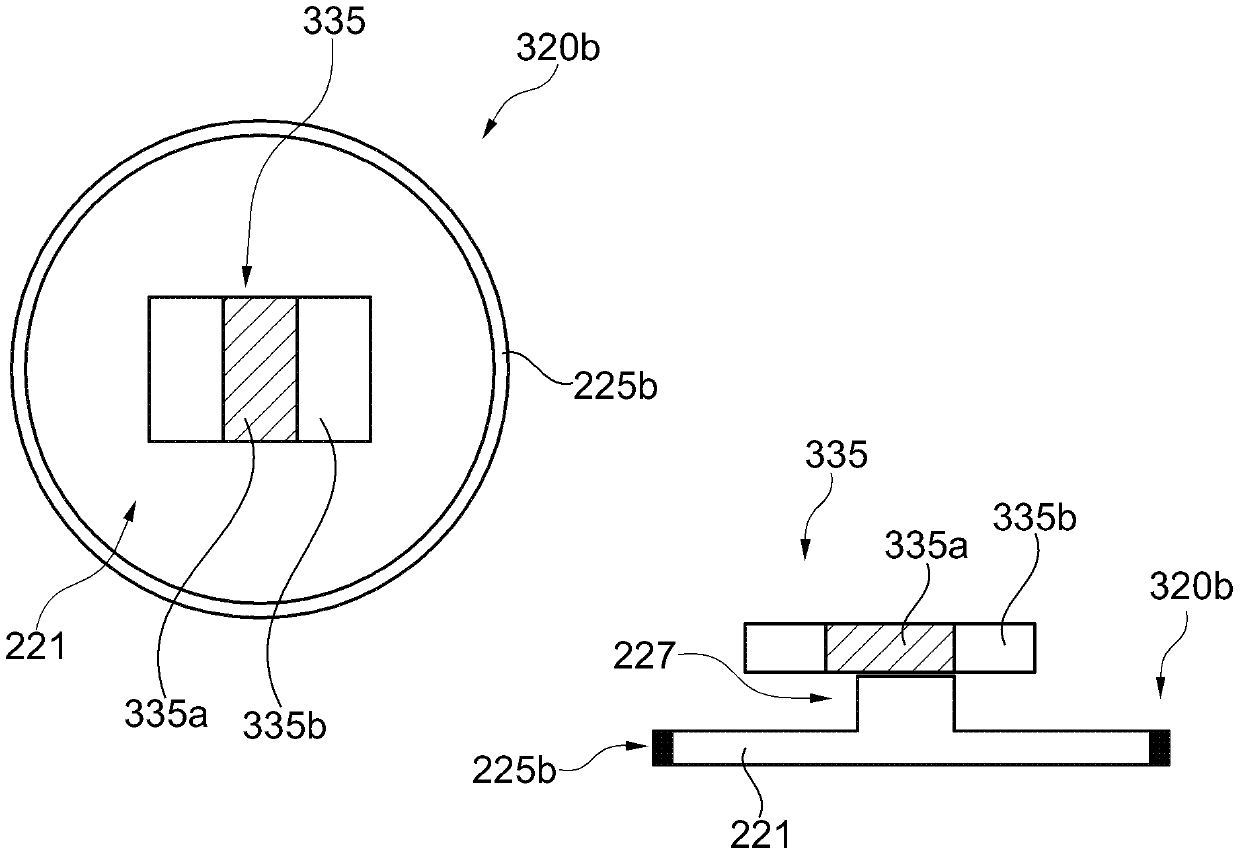

[0100] According to another embodiment, suitable markings are provided on the component-holding device (especially the straw). They can for example be designed as a surrounding circle to form a side reference. Set a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com