Sand and stone filtering device for oil production

A filter device, sand and stone technology, applied in the direction of filtration separation, filtration circuit, only multi-stage series refining process, etc., can solve the problems of low filtration efficiency, incomplete filtration, unclean filtration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

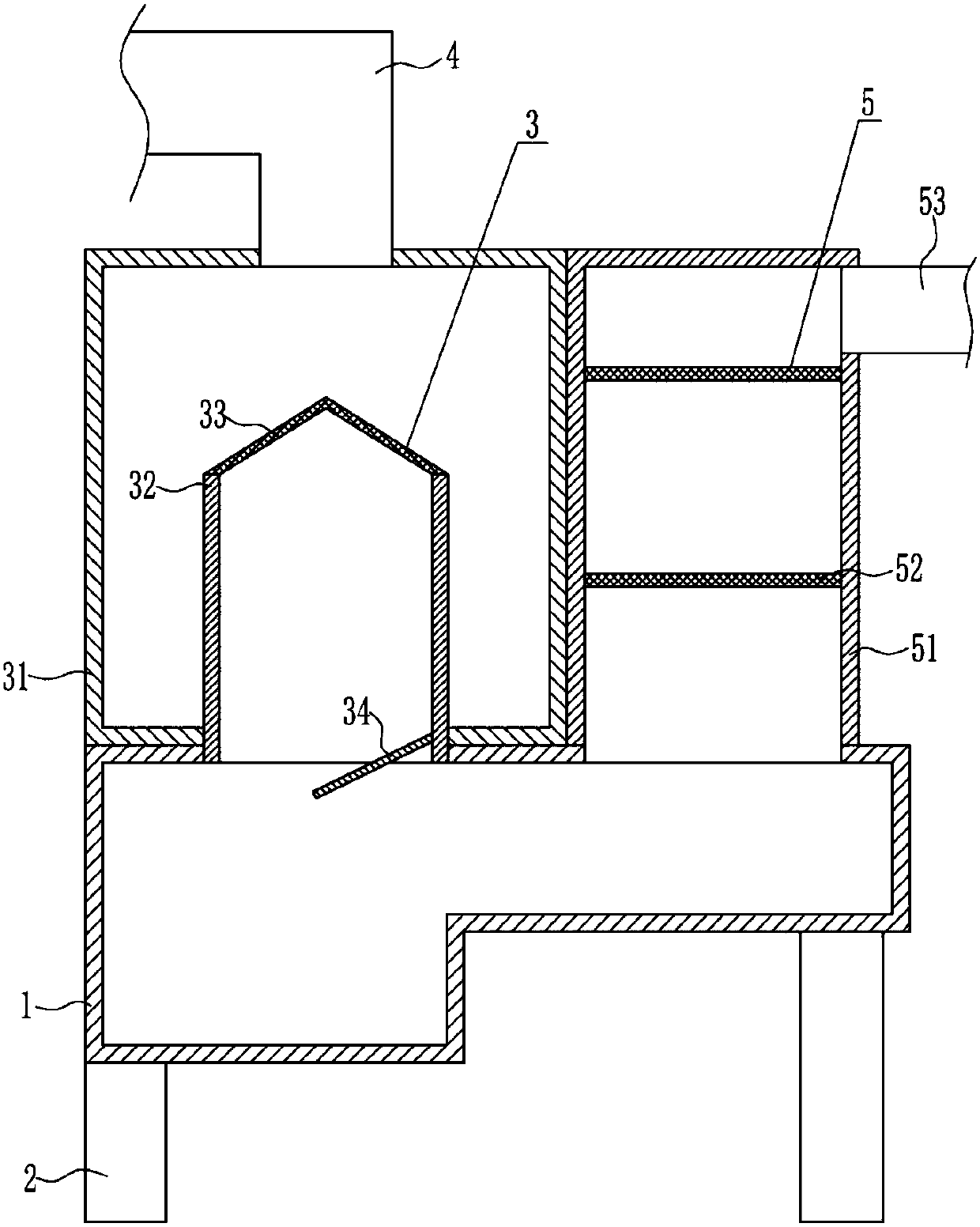

[0035] A sand filter device for petroleum exploitation, such as Figure 1-4 As shown, it includes a settling box 1, legs 2, a coarse filter 3, a feed pipe 4 and a fine filter 5, and the four corners of the bottom of the settling box 1 are equipped with a settling leg 2 by means of bolt connections, and the settling box 1 A coarse filter device 3 is provided on the left side of the top of the tank, a feed pipe 4 is provided on the top of the coarse filter device 3, and a fine filter device 5 is provided on the right side of the top of the sedimentation tank 1.

Embodiment 2

[0037] A sand filter device for petroleum exploitation, such as Figure 1-4 As shown, it includes a settling box 1, legs 2, a coarse filter 3, a feed pipe 4 and a fine filter 5, and the four corners of the bottom of the settling box 1 are equipped with a settling leg 2 by means of bolt connections, and the settling box 1 A coarse filter device 3 is provided on the left side of the top of the tank, a feed pipe 4 is provided on the top of the coarse filter device 3, and a fine filter device 5 is provided on the right side of the top of the sedimentation tank 1.

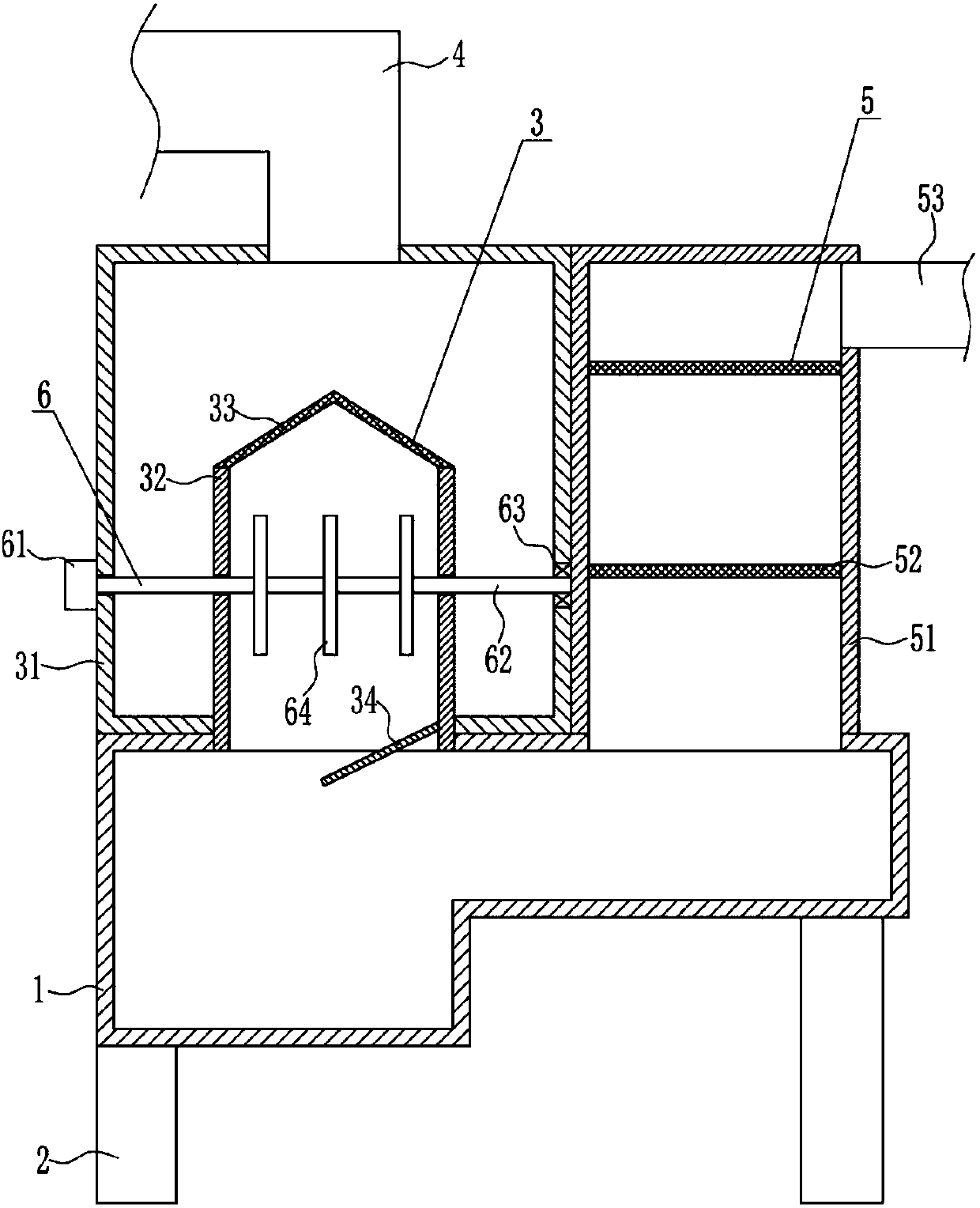

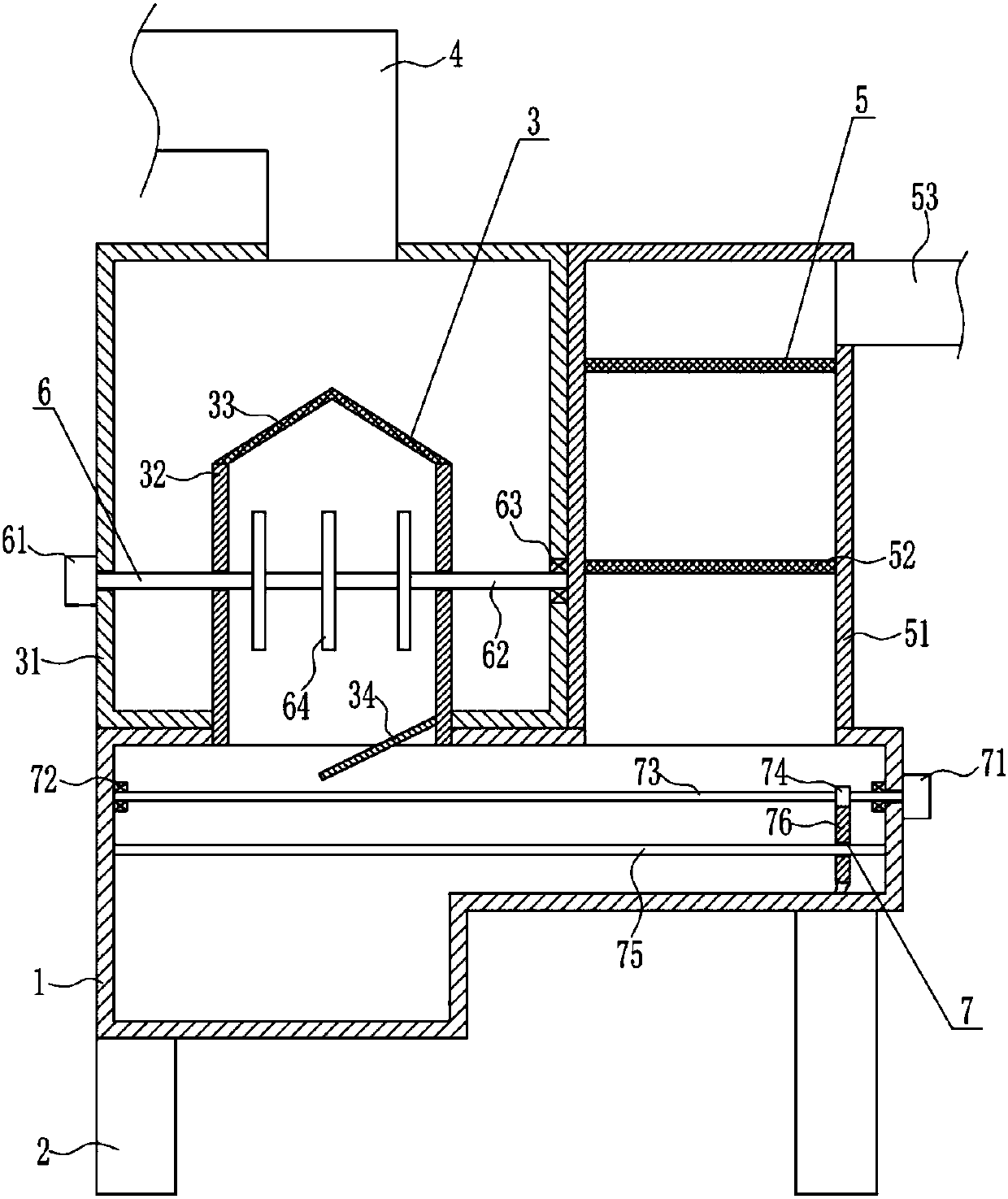

[0038] The coarse filtration device 3 includes a first box body 31, a frame body 32, a conical filter screen 33 and a slant plate 34. The left side of the top of the sedimentation tank 1 is connected with the first box body 31 by a bolt connection mode, and the feed pipe 4 It is connected to the middle of the top of the first box body 31 by means of bolt connection, the feed pipe 4 communicates with the first box body 3...

Embodiment 3

[0040] A sand filter device for petroleum exploitation, such as Figure 1-4 As shown, it includes a settling box 1, legs 2, a coarse filter 3, a feed pipe 4 and a fine filter 5, and the four corners of the bottom of the settling box 1 are equipped with a settling leg 2 by means of bolt connections, and the settling box 1 A coarse filter device 3 is provided on the left side of the top of the tank, a feed pipe 4 is provided on the top of the coarse filter device 3, and a fine filter device 5 is provided on the right side of the top of the sedimentation tank 1.

[0041] The coarse filtration device 3 includes a first box body 31, a frame body 32, a conical filter screen 33 and a slant plate 34. The left side of the top of the sedimentation tank 1 is connected with the first box body 31 by a bolt connection mode, and the feed pipe 4 It is connected to the middle of the top of the first box body 31 by means of bolt connection, the feed pipe 4 communicates with the first box body 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com