Vacuum low-pressure ultra-shallow layer carburizing heat treatment method

A heat treatment method, vacuum and low pressure technology, applied in coating, solid diffusion coating, metal material coating process, etc., can solve problems such as furnace gas aging, blind holes of parts, dense packaging production, etc., to improve efficiency and simplify operation , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

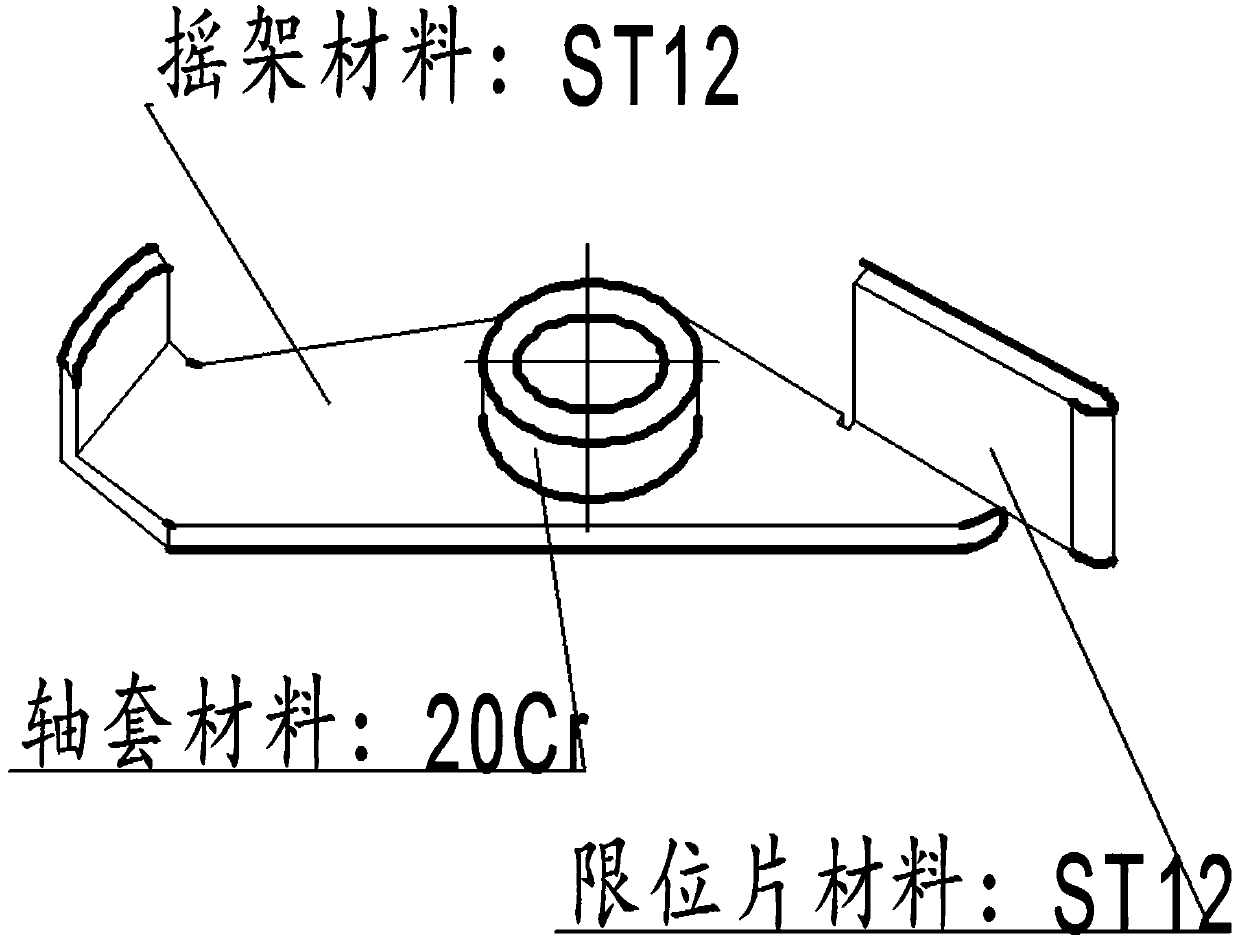

[0058] The invention proposes a vacuum low-pressure ultra-shallow layer carburizing heat treatment method, which forms a "carburizing-diffusion" pulsed carburizing process by vacuuming to carry out carburizing stage treatment in the carburizing process; the carburizing process of parts is a continuous process. The pulse cycle process of automatic vacuuming and replenishing carburizing agent. The parts are heated and carburized in a cycle within the set low vacuum upper and lower limits, and the furnace gas is repeatedly discharged and replaced by the new within the set time period, which solves the problem of blind holes, dead ends, dense production, and furnace gas aging of parts during the carburizing process. , The uniformity of the infiltration layer and other difficulties. The heating chamber used in the present invention is preferably a vacuum carburizing furnace (VCOQ2-150).

[0059] The carburizing heat treatment process uses vacuum furnace technology to carry out low...

Embodiment 2

[0061] This embodiment is further optimized on the basis of the above-mentioned embodiments, and further in order to better realize the present invention, the following setting method is adopted in particular: the "carburizing-diffusion" pulsed carburizing process is specifically:

[0062] 1) Carburizing: Under vacuum conditions, feed carburizing gas into the heating chamber and keep it, and carburize the parts; the preferred flow rate of carburizing gas is 1500-4800L / h;

[0063] 2) Diffusion: After carburizing, vacuumize the heating chamber, extract the aging gas, and maintain it, and carry out diffusion treatment on the parts;

[0064] 3) Cycle step 1) and step 2) until the set carburizing stage time is over. When setting, the preferred carburizing stage time is 5~120min.

[0065] Vacuum low-pressure ultra-shallow carburizing realizes a carburizing process that adapts to different materials and part structures by changing the introduction of carburizing gas and the removal o...

Embodiment 3

[0067]This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, the following setting method is adopted in particular: the carburizing retention time in the initial carburizing stage is greater than or equal to the diffusion retention time, In the late carburizing stage, the carburizing retention time is less than or equal to the diffusion retention time; due to the vacuum pumping and carburizing agent (carburizing gas) technology, by adjusting the vacuum and carburizing agent time is to adjust The pulse interval time can well adjust the carbon concentration on the surface of the carburized layer, and the depth of the carburized layer can be adjusted by adjusting the carburized time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com