Transmission spindle shifting fork structure

A technology for driving the main shaft and shift fork shaft, which is applied in the direction of transmission device control, controlled components, instruments, etc. It can solve the problems of unreasonable structure, inflexible and smooth switching, and different problems, and achieve reasonable structure, small wear and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

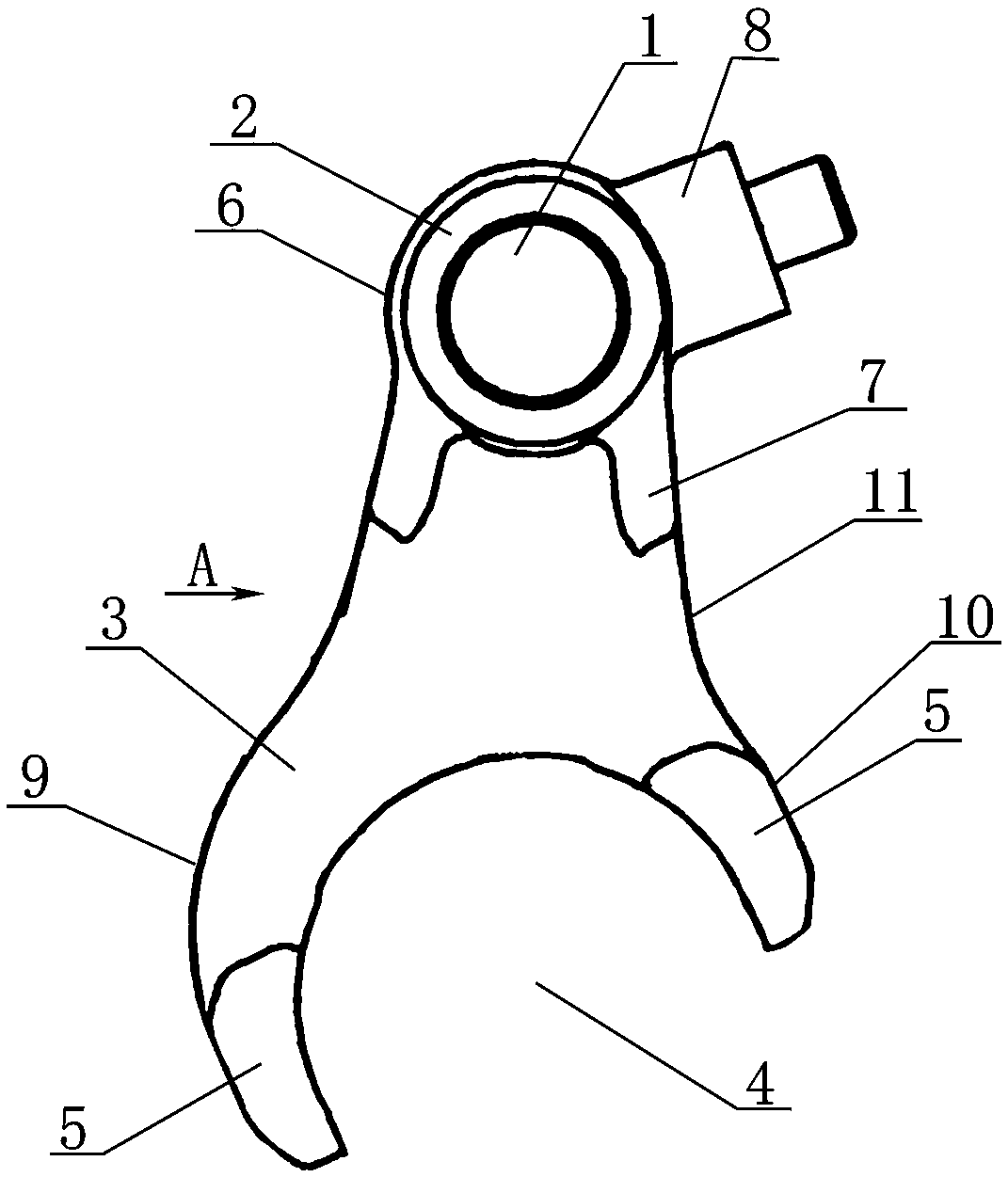

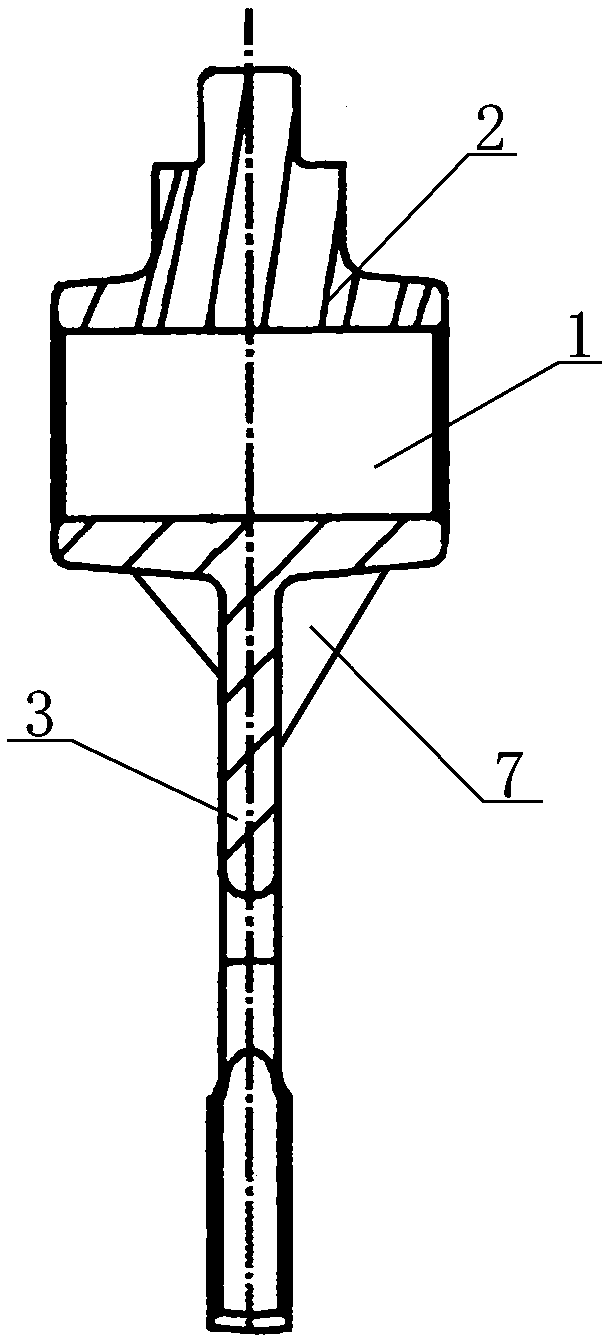

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, a transmission fork structure of the present invention is mainly composed of a fork shaft 2 provided with an axial through hole 1 and a sheet-shaped fork body 3. The front of the fork body 3 The part is provided with a semicircular shifting groove 4, the notch of the semicircular shifting groove 4 faces one side, and the surface of the two outer ends of the notch is processed with a fork plane 5, and a fork plane is coated on the fork plane 5. layer of wear-resistant coating; the lower end of the shift fork body 3 is connected to the middle section of the shift fork shaft 2, and the outer wall of the shift fork shaft 2 is covered with arc edges 6 on both sides, which strengthens the shift fork body 3 The connection with the shift fork shaft 2; the two sides of the shift fork body 3 are respectively connected with thickened inclined ribs 7 to the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com