A split adjustment frame for optical lens

An optical lens, split-type technology, applied in optics, optical components, instruments, etc., can solve the problem of insufficient installation space for common aperture optical lenses, and achieve the effect of solving the problem of insufficient installation space, easy assembly and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

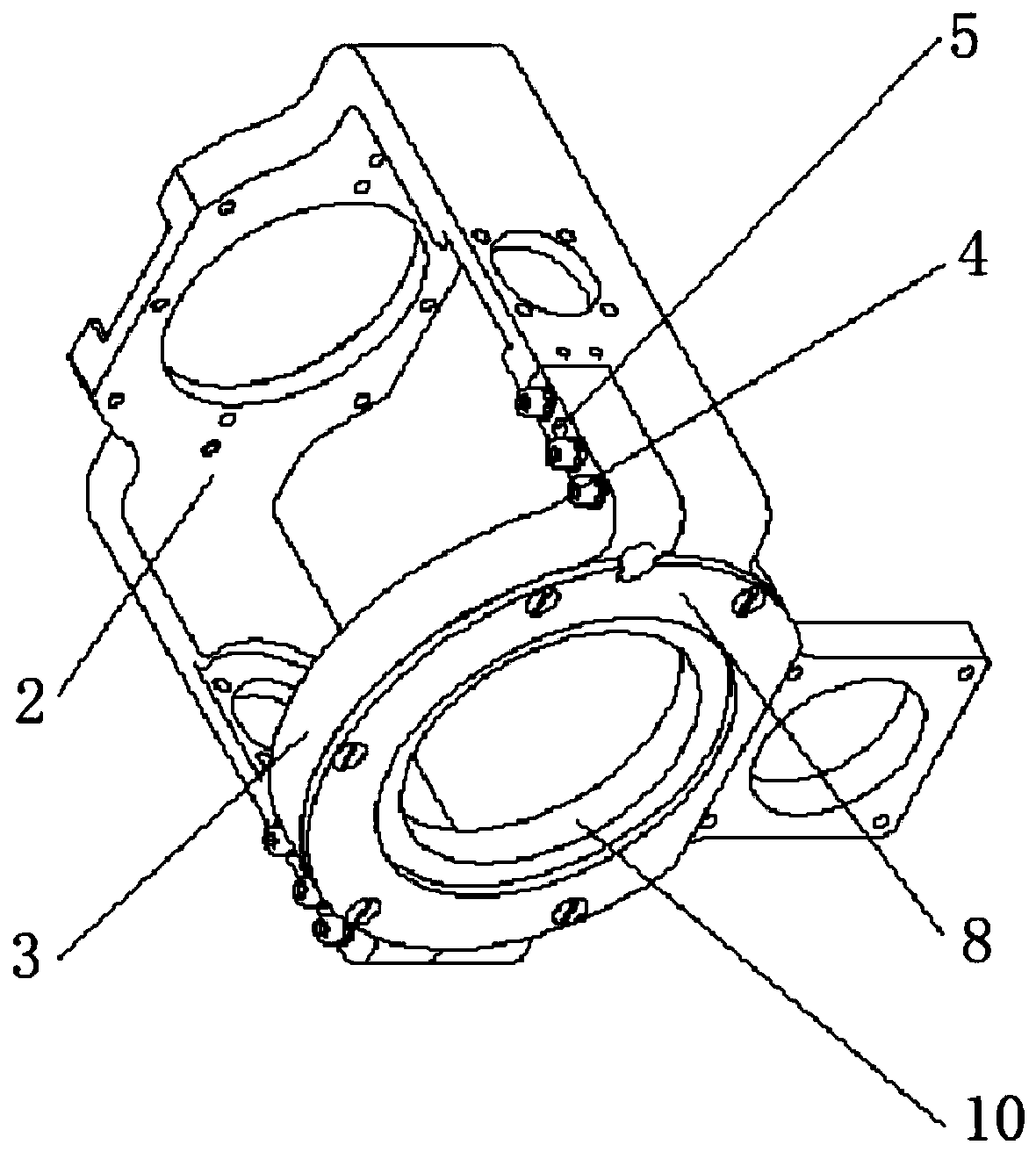

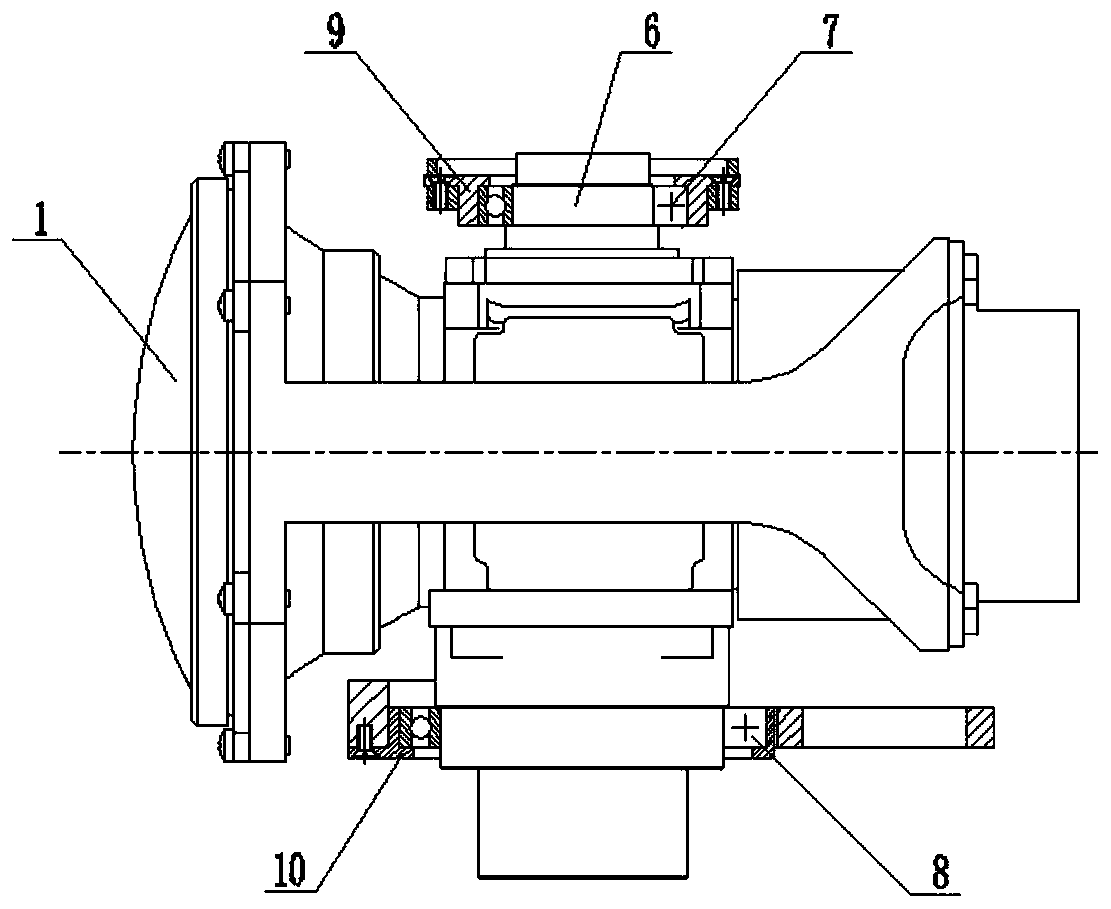

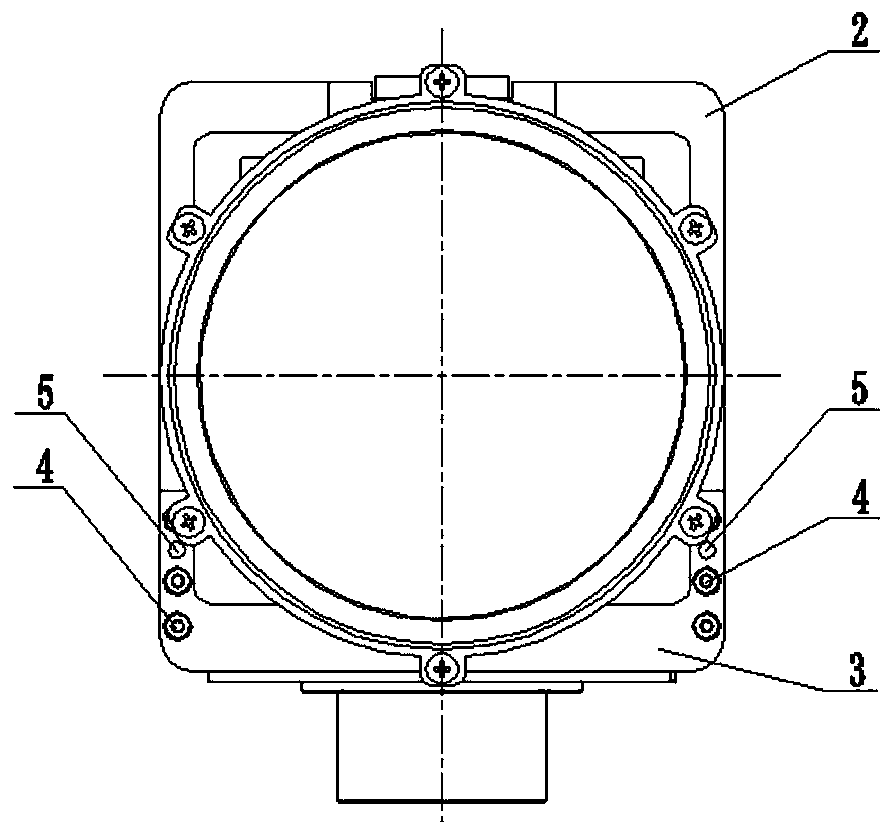

[0020] This embodiment provides a split adjustment frame for optical lenses, see attached figure 1 and 2 , comprising: a first frame 2, a second frame 3, a connecting screw 4, a positioning pin 5, an upper shaft 6, a first bearing 7, a second bearing 8, an upper bearing seat 9 and a lower bearing seat 10;

[0021] The part to be matched and installed is a co-aperture optical lens 1;

[0022] The first frame 2 is a U-shaped frame, and its three surfaces are respectively processed with through holes, wherein a rotating shaft connected with the co-aperture optical lens 1 is installed in the through holes on the opposite two sides;

[0023] The second frame 3 is an arc-shaped frame, and the end surfaces at both ends of the frame respectively extend two connecting blocks docked with the first frame 2;

[0024] The overall connection relationship is as follow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com