Making method of antenna and mobile equipment

A manufacturing method and mobile device technology, applied in antennas, antenna components, antenna supports/installation devices, etc., can solve the problems of poor bonding between the antenna and the plastic mobile phone back shell, the influence of mobile phone installation, and the occupation of the internal installation space of the mobile phone, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

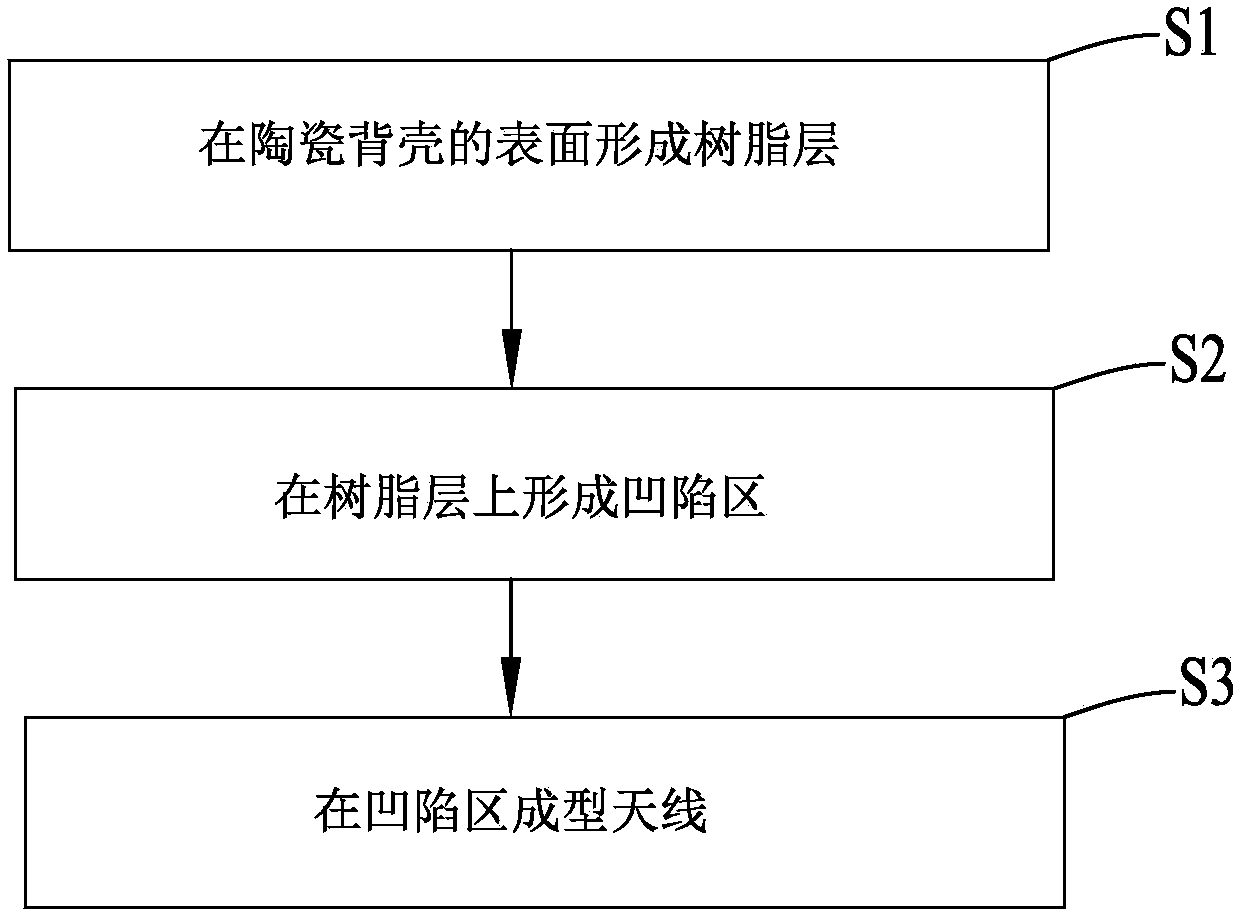

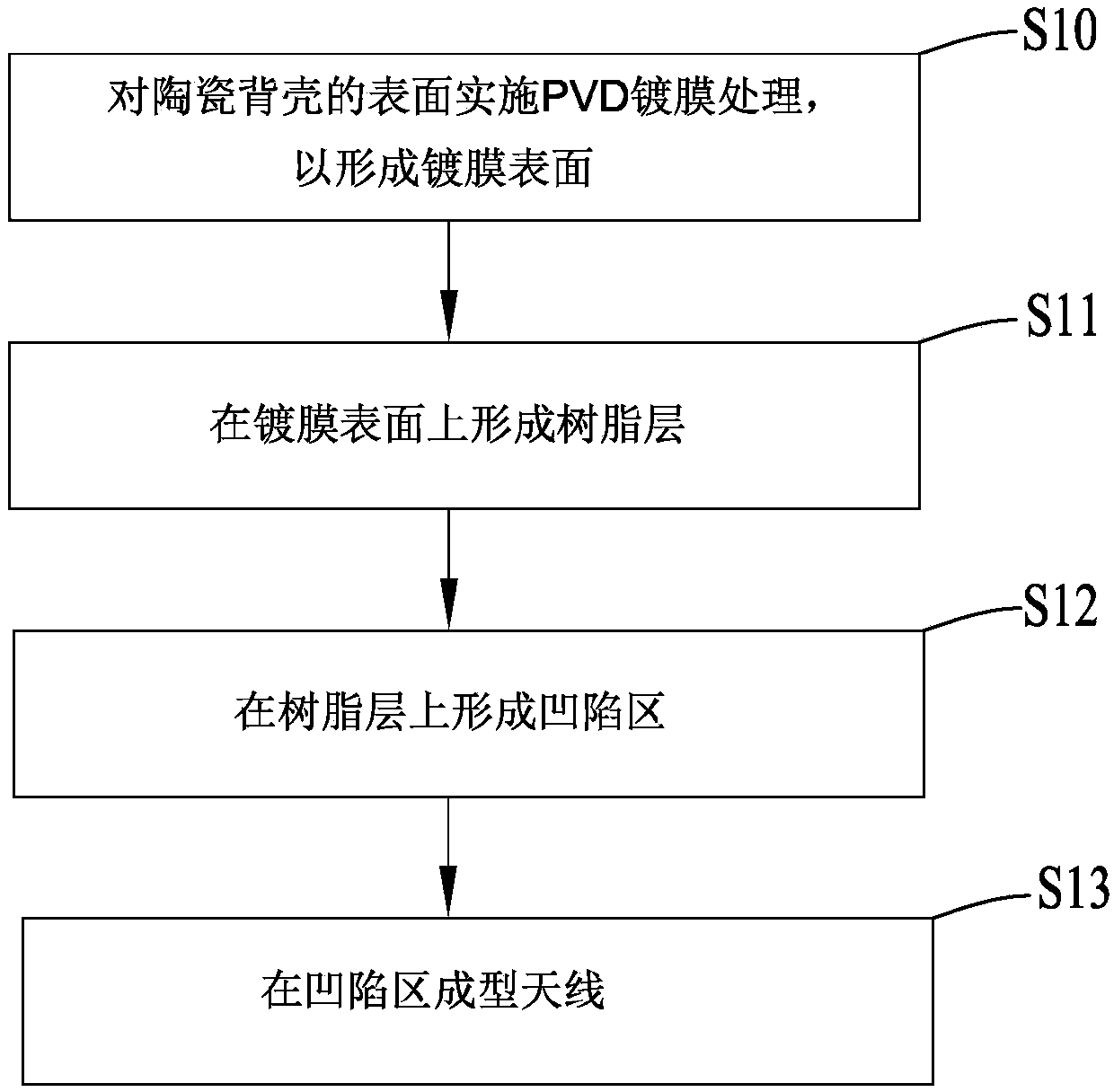

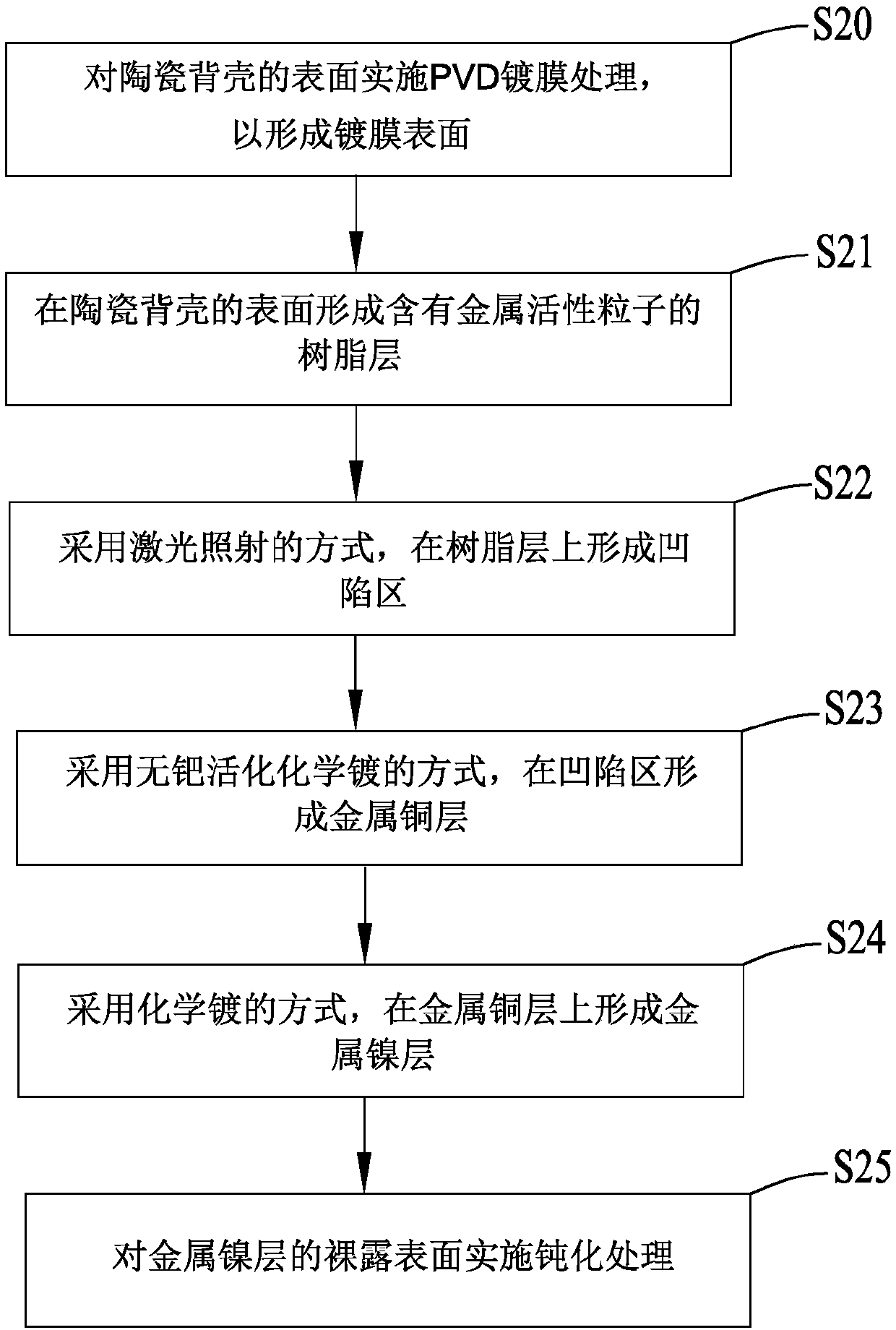

[0053] Such as figure 1 , Figure 5 , Image 6 with Figure 7 As shown, among them, figure 1 A schematic flow chart of a method for manufacturing an antenna provided by an embodiment of the present invention, which includes the following steps:

[0054] S1, forming a resin layer 2 on the surface of the ceramic back shell 1;

[0055] The ceramic back shell 1 can specifically be a back shell made of ceramic material in a mobile device, and an appropriate ceramic raw material can be selected according to performance requirements to make a finished product of the ceramic back shell 1; the aforementioned back shell can be a plane back shell, or It can be a curved back shell; the staff can set the thickness of the ceramic back shell 1 according to actual needs, for example, the thickness of the ceramic back shell 1 can be betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com