A small-size vibrating type flax breeding and strip sowing machine

A vibrating seed drill technology, applied in the directions of sowing seeders, seeder parts, etc., can solve the problems that the openers are easy to block soil, the openers are easy to deform, and the seed conveying pipes and fertilizer conveying pipes are easy to loosen, etc. To achieve the effect of ensuring the uniformity of sowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

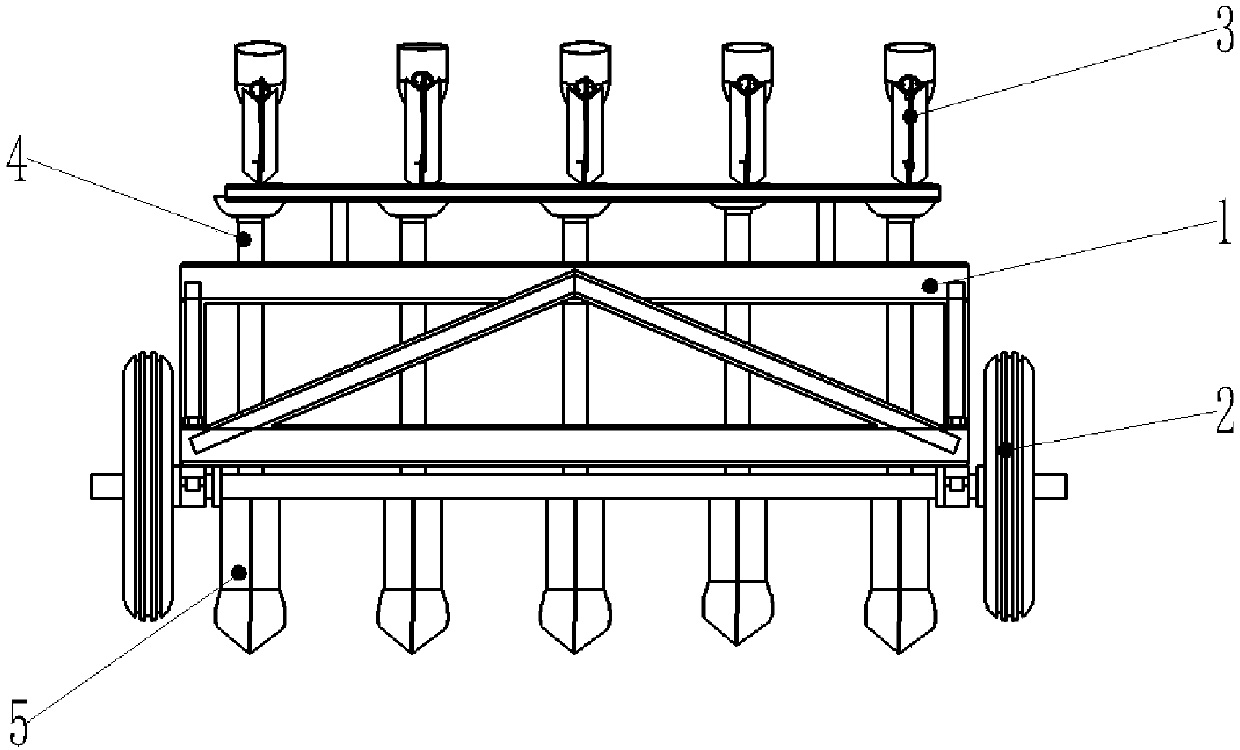

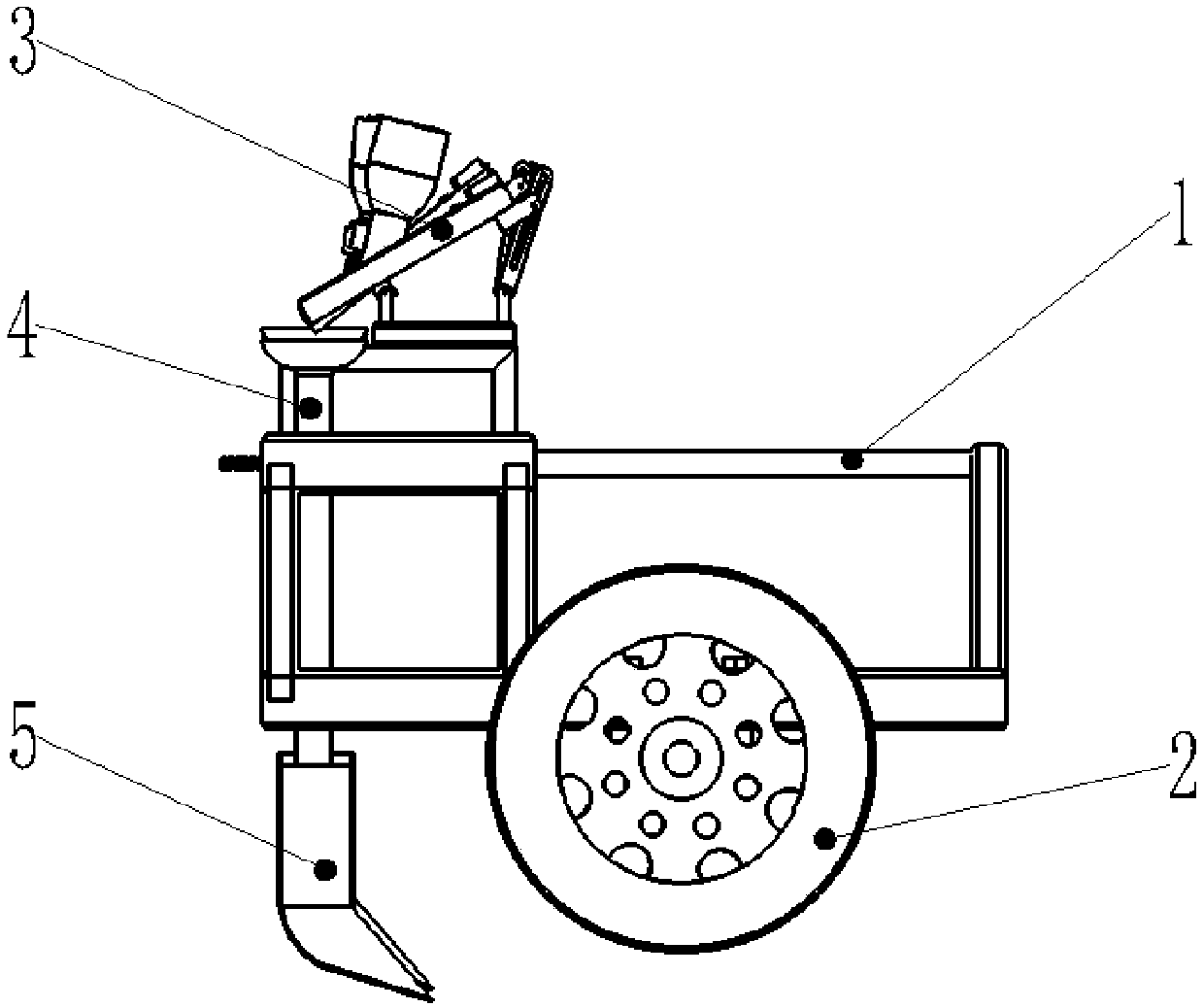

[0014] like Figures 1 to 4 As shown, the described small-sized vibrating flax seed drill includes a frame 1, which is characterized in that a support wheel 2 is provided below the frame 1, and a vibrating seed meter 3 is provided above the frame 1. A seed pipe 4 is installed below the vibrating seed meter 3, and a ditch opener 5 fixedly connected to the frame 1 is arranged below the seed pipe 4.

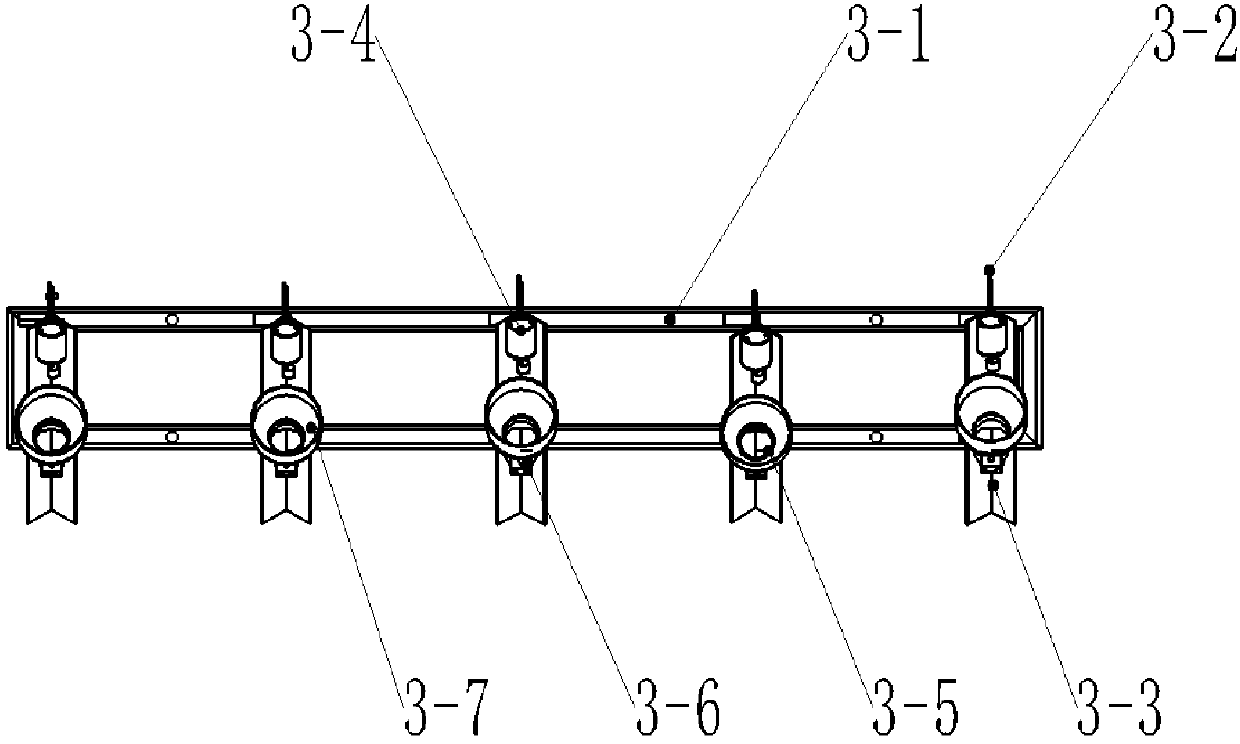

[0015] Further, the vibrating seed metering device 3 includes a seed metering device supporting frame 3-1 connected with the frame 1, and one end of the seed groove inclination adjustment rod 3-2 is connected with the seed metering device supporting frame 3-1, and the seed groove inclination angle The other end of the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com