Machining Center Mechanism

A machining center and machine body technology, applied in the field of mechanical parts processing, can solve problems such as the detachment of the end of the spindle head, the reduction of the safety of the machining center mechanism, and the collision of the spindle head with the worktable or base, so as to avoid collision damage and improve the use of safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The core of the present invention is to provide a machining center mechanism whose use safety is improved.

[0038] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

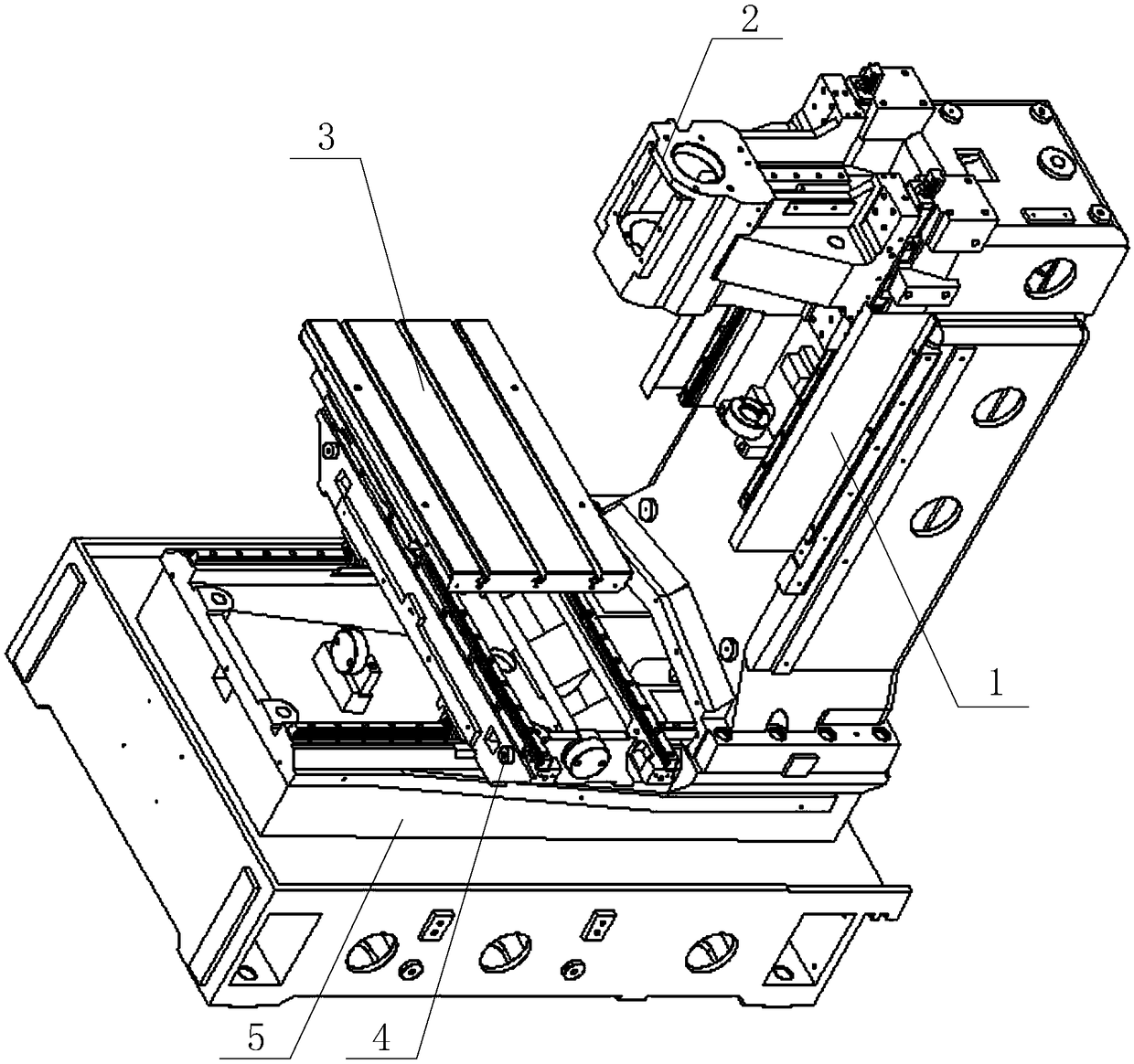

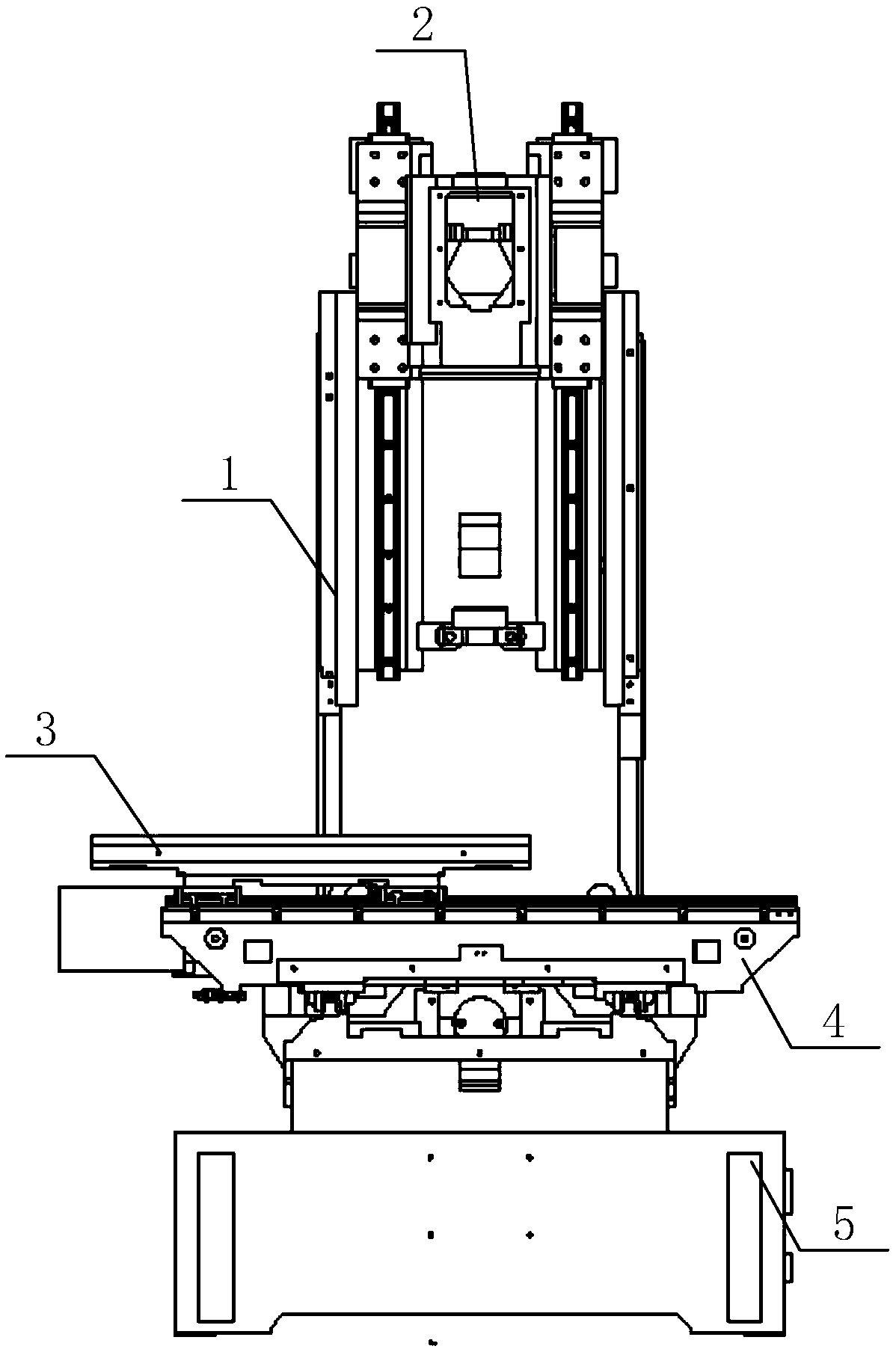

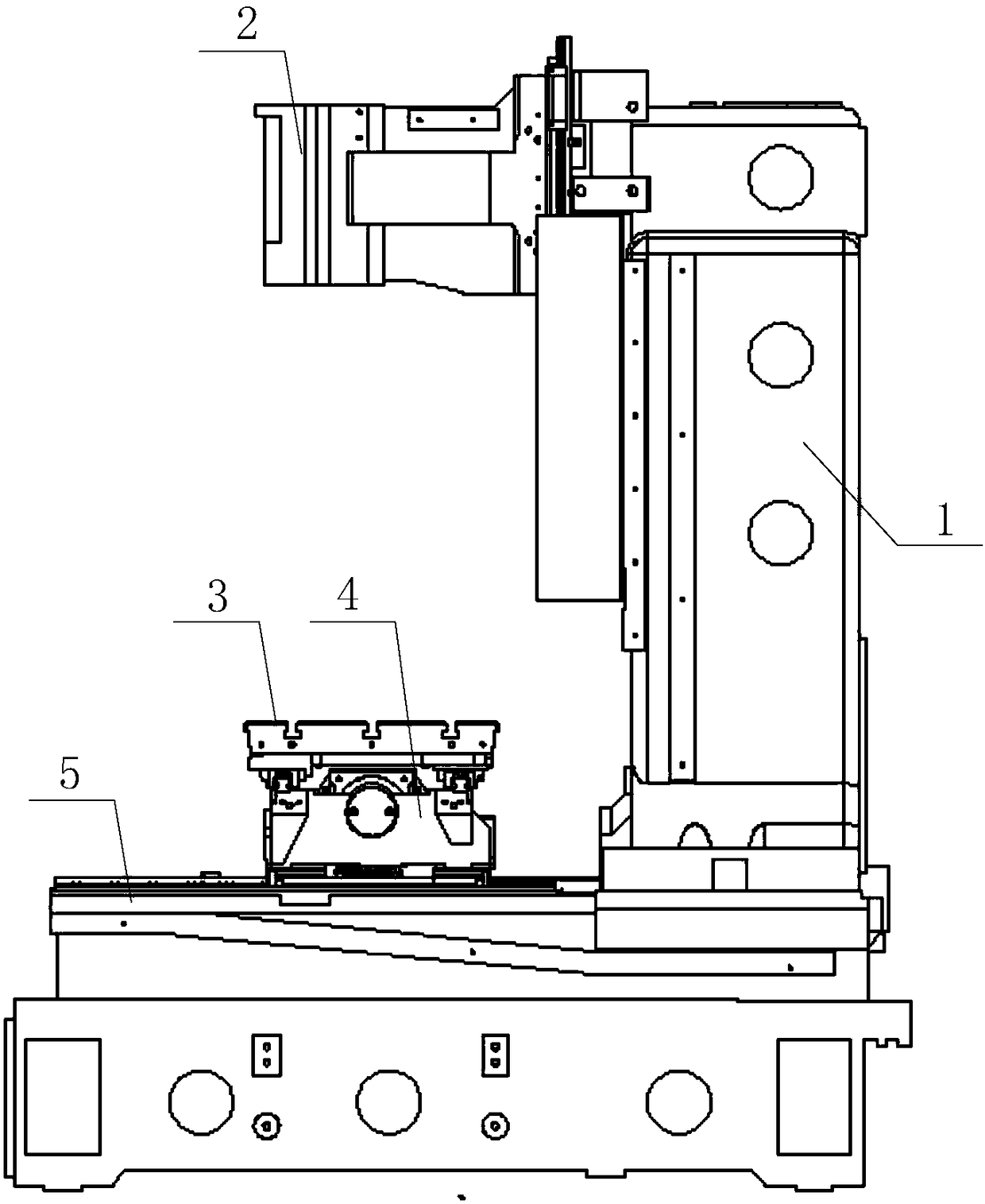

[0039] Please refer to Figure 1 to Figure 13 , in a specific embodiment, the machining center mechanism provided by the specific embodiment of the present invention includes a base 5, a column 1 and a spindle head 2 that is installed on the column 1 and can slide up and down along the column 1, and the column 1 is installed on the base 5 Above, the column 1 includes the column body 11, the shaft head guide rail 12, the shaft head anti-collision table 13 and the shaft head limit switch connected with the shaft head anti-collision table 13 and used to control the spindle head 2 to stop moving downward, two The spindl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com