A roller compacted concrete dam and its construction method

A technology of roller compacted concrete and construction method, applied in dams and other directions, can solve the problems of poor economy, poor effect, not giving full play to the rapid dam building of roller compacted concrete and cost saving, etc., to achieve simple temperature control measures and improve construction speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

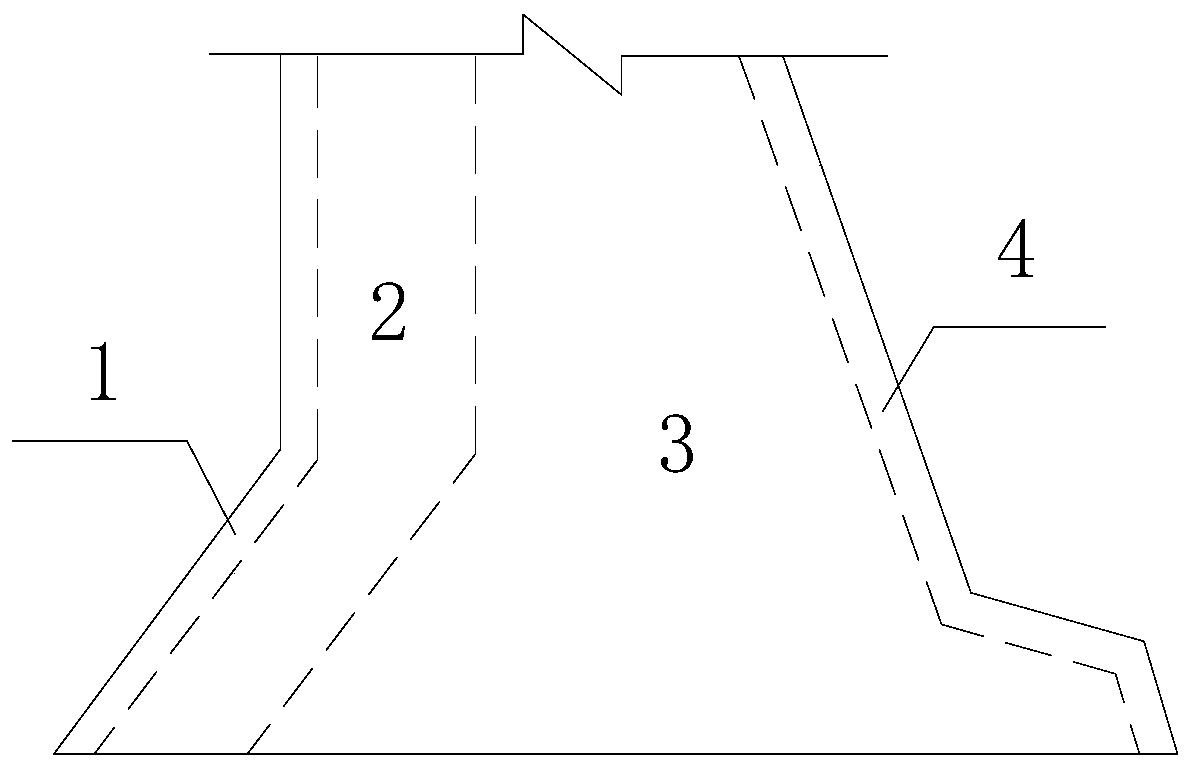

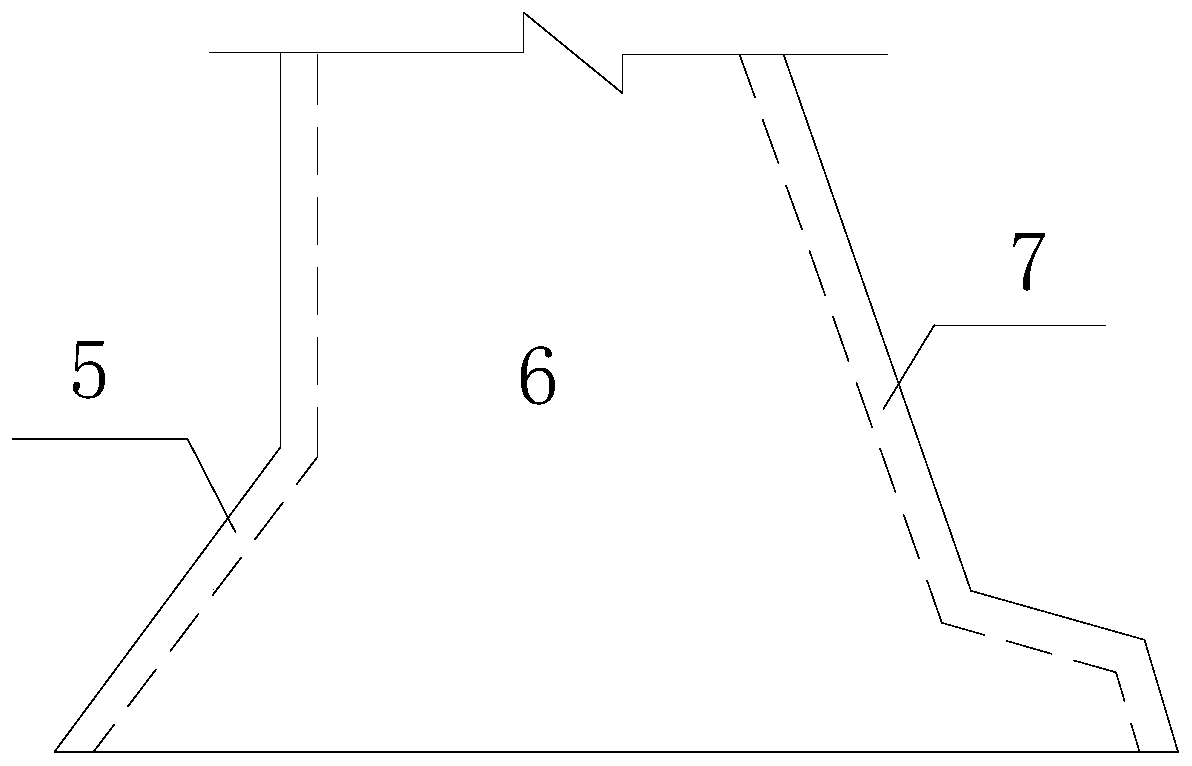

[0024] refer to figure 2 , the present invention is a roller compacted concrete dam, the roller compacted concrete dam comprises a dam body upstream facing water surface area 5, a dam body internal area 6 and a dam body downstream surface area 7, the dam body internal area 6 is located at the dam body upstream facing water surface area 5 Between the area 7 and the downstream surface of the dam body, the upstream surface area 5 of the dam body is made of large-graded concrete with low plasticity and heat of hydration; Concrete, large graded concrete with low plasticity and low heat of hydration, three-grade roller compacted concrete and metamorphic concrete are mixed with a heat of hydration inhibitor.

[0025] The roller compacted concrete dam is divided into three areas, which are divided into three areas from upstream to downstream: the upstream surface area 5 of the dam body, the internal area 6 of the dam body, and the downstream surface area 7 of the dam body. Compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com