Method for controlling maximum temperature of large-volume normal-temperature concrete

A technology with the highest temperature and control method, applied in clay preparation devices, chemical instruments and methods, construction, etc., can solve problems affecting concrete pouring efficiency and mixing quality, prolong concrete mixing time, and restrict construction progress, etc., to reduce pre-cooling The effect of management personnel investment, improvement of mixing quality, and simplification of temperature control measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

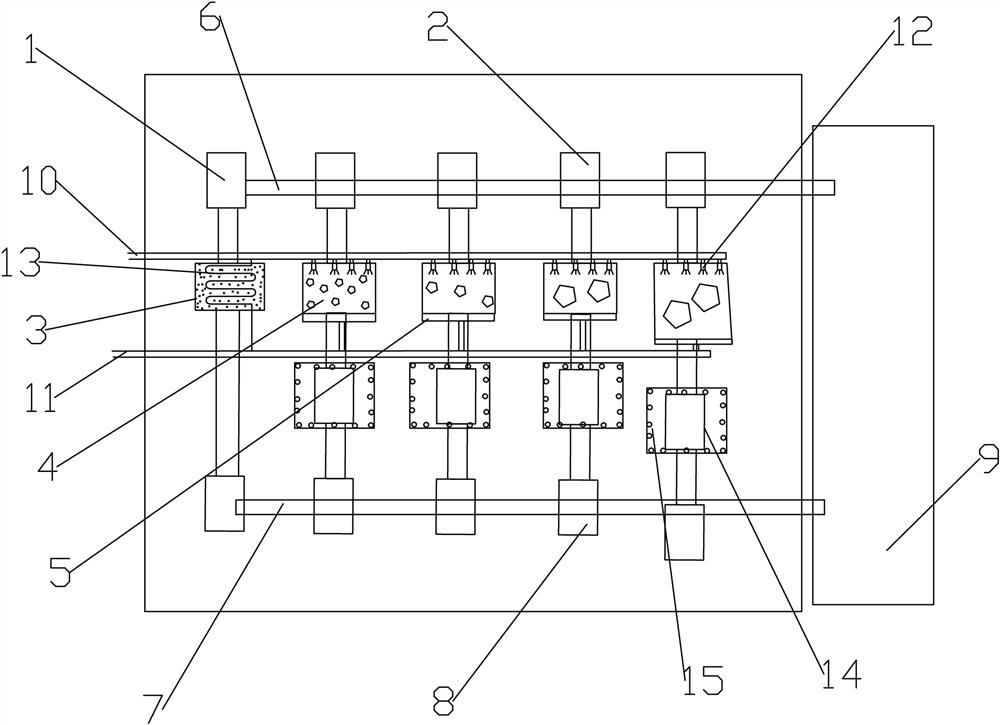

[0026] Such as figure 1 As shown, a method for controlling the maximum temperature of large-volume normal-temperature concrete includes the following steps:

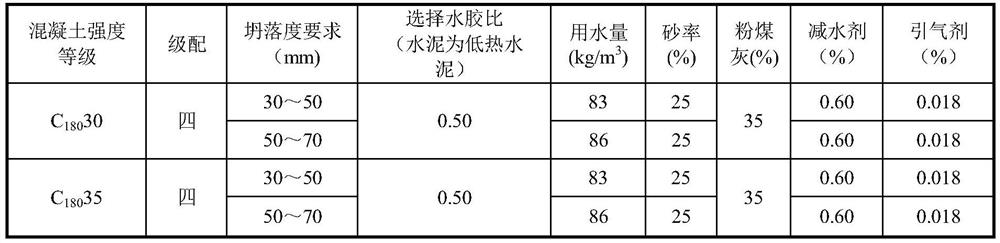

[0027] Step 1. According to the design of the warehouse surface, formulate the material requirement plan for the warehouse surface to be poured in advance, and start the batching plan in advance. Before pouring concrete at room temperature in the dam, it is necessary to use the finite element method to simulate and calculate the external ambient temperature, cooling water pipe spacing, and cooling water temperature of different temperature control and anti-cracking requirements according to the maximum temperature control standard of the concrete temperature control index specified in the design requirements. , water flow, water duration, and the relationship between the actual maximum temperature control value, and carry out targeted productive tests to clarify the above indicators, and solidify and implement them in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com