Slotting-free ceramsite building brick

A ceramsite and bricklaying technology, applied in building components, buildings, building structures, etc., can solve the problems of brick cracking, weak wall structure, low strength, etc., and achieve good strength without causing wall structure. Not firm, good sound insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for limiting the present invention.

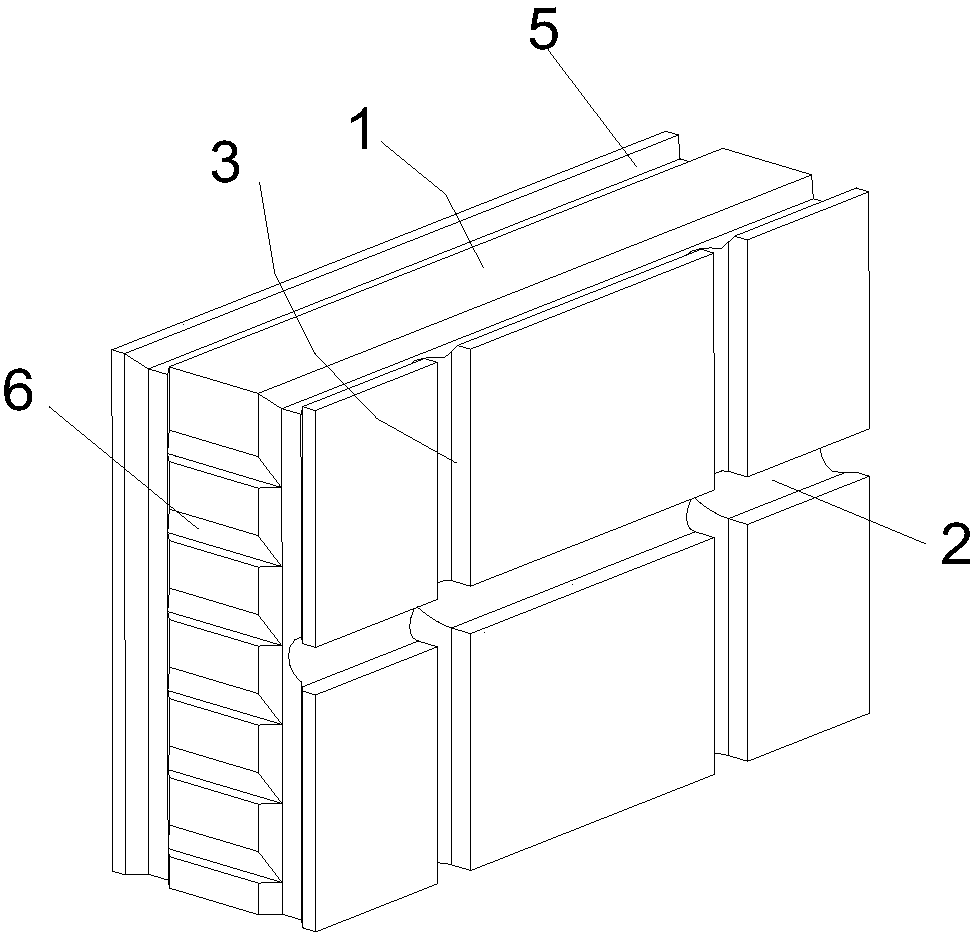

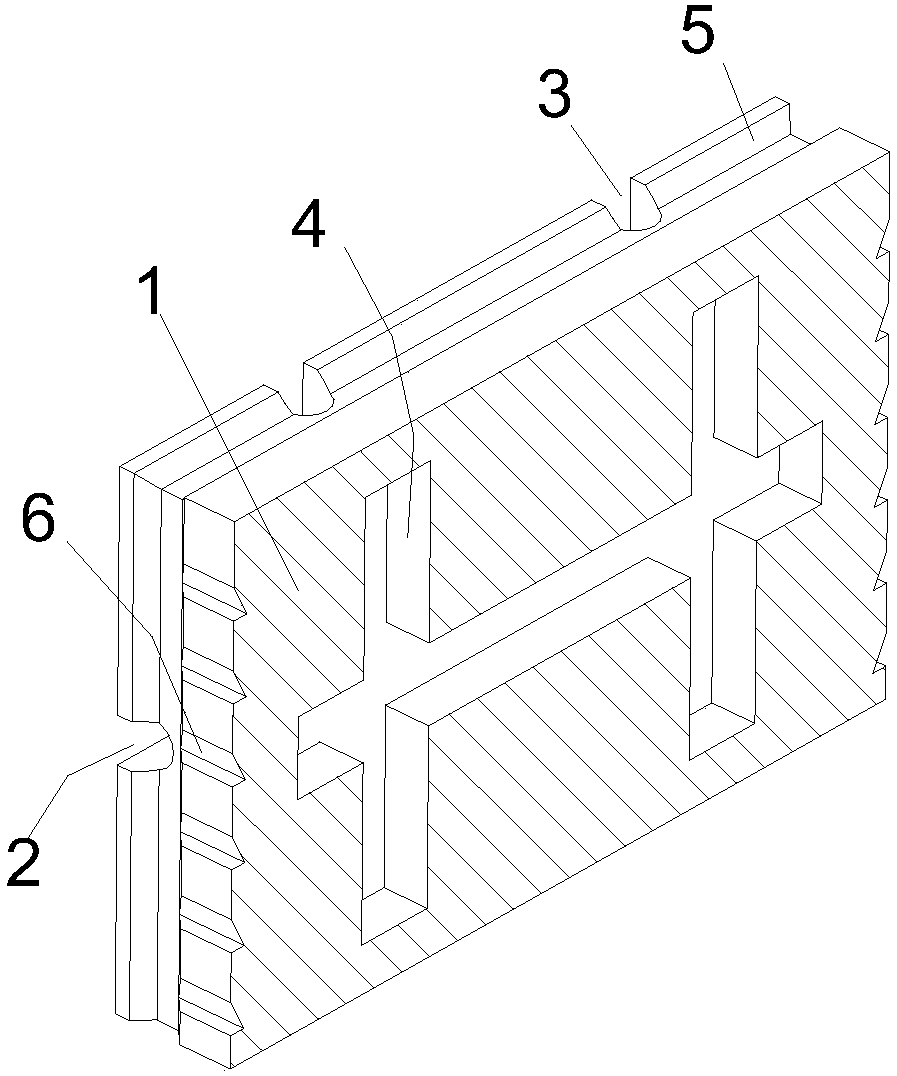

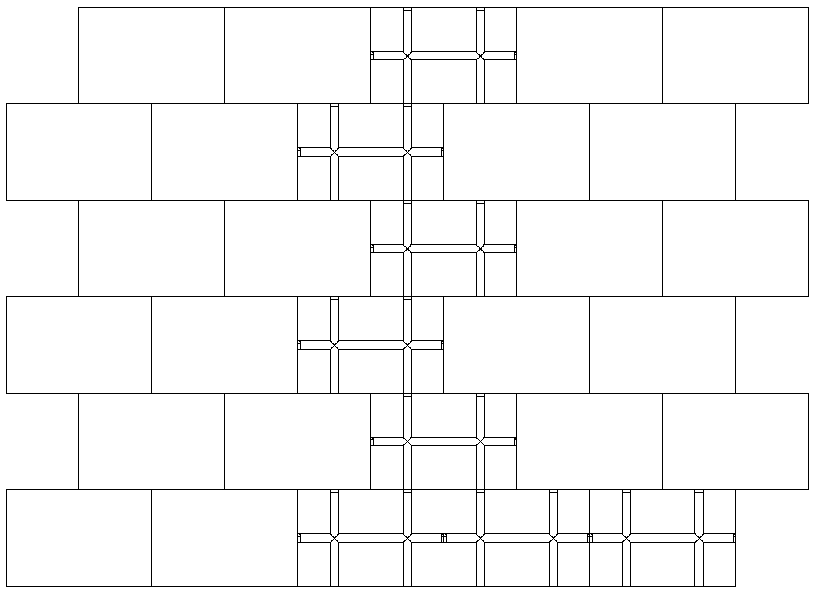

[0020] Example. A slot-free ceramsite brick, such as figure 1 and figure 2 As shown, it includes a cuboid body 1 made of ceramsite concrete. The front side of the body 1 is provided with a transverse wire groove 2 and two longitudinal wire grooves 3, and the back of the horizontal wire groove 2 and the longitudinal wire groove 3 is provided with Cavity 4 located in body 1 . The two longitudinal wire slots 3 are symmetrically distributed on both sides of the longitudinal midline of the front side of the body 1 and the distance between them is half of the distance between the left and right sides of the body 1 .

[0021] The body 1 is provided with two grooves 5, the grooves 5 run through the left side, the top surface and the right side of the body 1 in sequence, and the two grooves 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com