Sound-absorbing body

A technology of sound body and sound-absorbing cotton, which is applied in the direction of sound-producing equipment, instruments, layered products, etc., can solve the problems of filling a single sound-absorbing cotton and low sound-absorbing efficiency, and achieve the best sound-absorbing effect and the effect of large loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be described in further non-limiting detail below in combination with preferred embodiments and accompanying drawings.

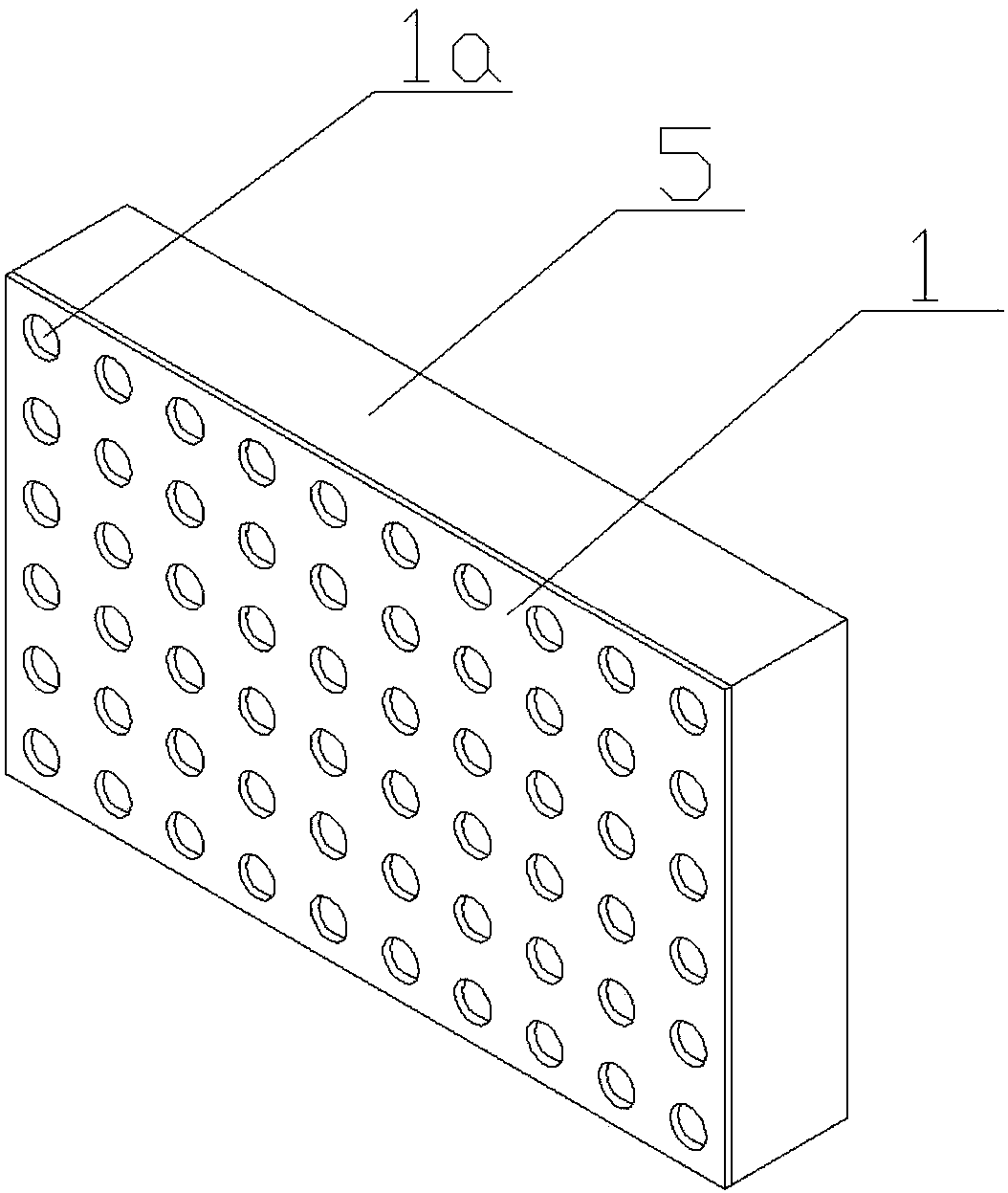

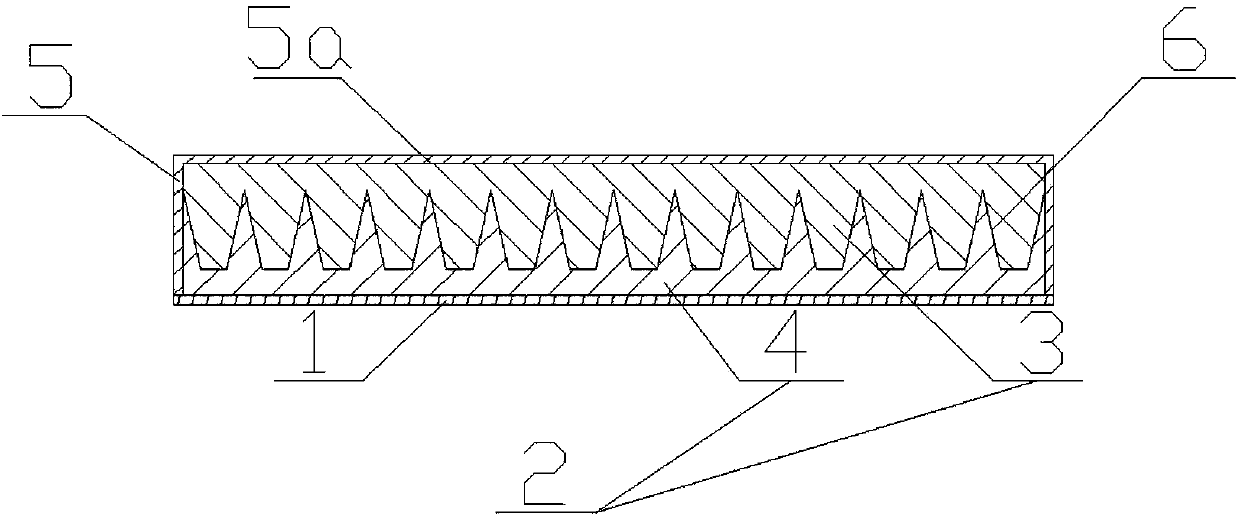

[0013] Such as Figure 1 to Figure 2 As shown, the sound-absorbing body corresponding to a preferred embodiment of the present invention includes a perforated plate 1, a housing 5 and a sound-absorbing assembly 2, the housing 1 has an inner cavity and an opening, the perforated plate 1 can close the opening, and the sound-absorbing assembly 2 It is arranged in the inner cavity of the housing 1. Both the casing 5 and the perforated plate 1 can be made of a thin metal plate through a sheet metal process, or wood materials can be used. The surface of the perforated plate 1 is provided with many small holes 1a.

[0014] The sound-absorbing component 2 is composed of at least two materials with different acoustic properties interlaced. The interface 6 of the two materials with different acoustic proper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com