Aluminum honeycomb ceiling board with micro-perforated sandwich layer

A technology of micro-perforation and sandwich layer, applied in the direction of ceiling, building components, buildings, etc., can solve the problems of poor sound absorption effect, difficult interlayer processing, and peeling of adhesive layer, so as to increase sound absorption efficiency and increase connection The effect of stability and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

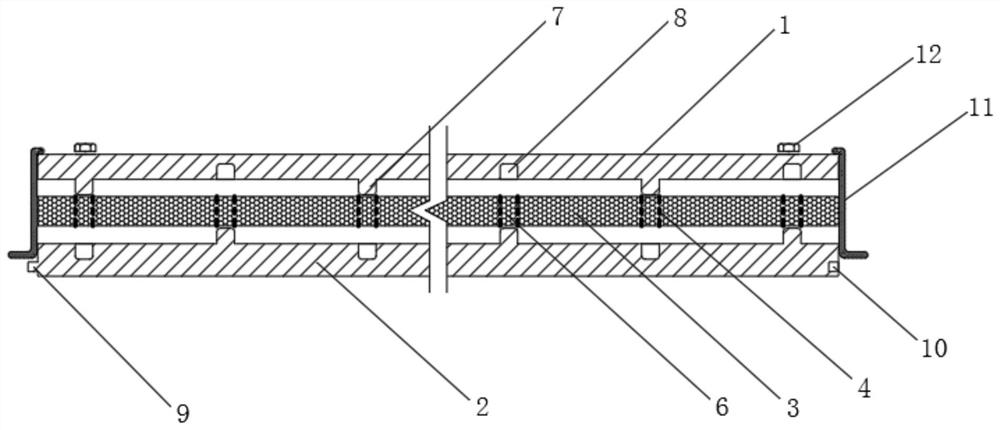

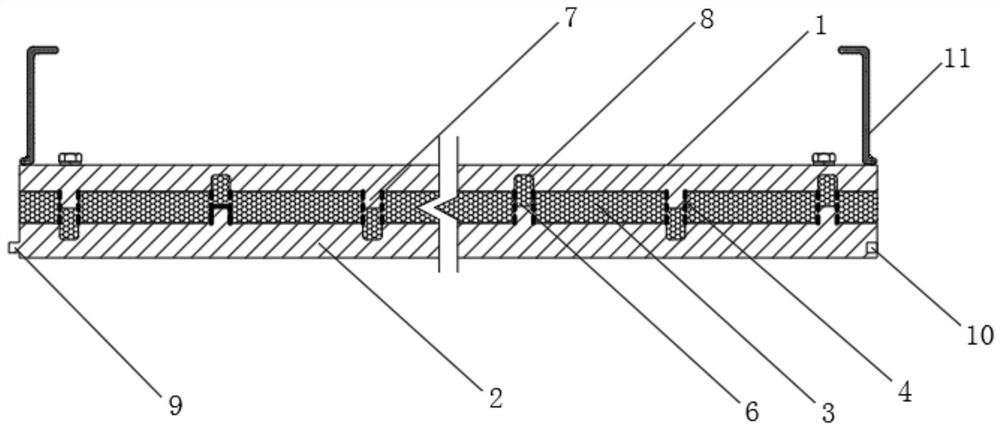

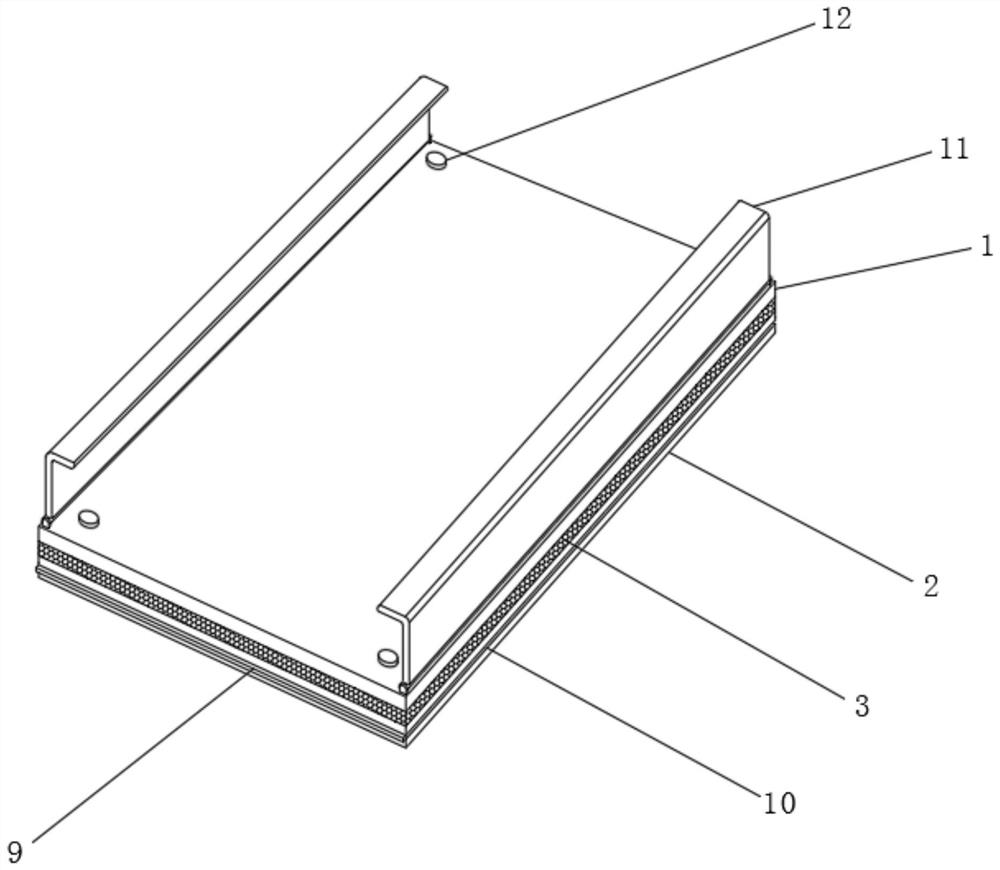

[0031] Such as Figure 1-6 As shown, an aluminum honeycomb ceiling panel with a micro-perforated sandwich layer includes an upper aluminum plate 1, a lower aluminum plate 2, and a micro-perforated sandwich layer 3 bonded between the upper aluminum plate 1 and the lower aluminum plate 2, in order to reinforce the three Or, the upper aluminum plate 1, the lower aluminum plate 2 and the micro-perforated sandwich layer 3 can also be fixedly connected by screws 12, the screws 12 are installed from the side of the upper aluminum plate 1, and the lower aluminum plate 2 is a decorative surface.

[0032] The micro-perforated sandwich layer 3 is evenly opened with a number of breakable dotted line grooves 4, and each of the breakable dotted line grooves 4 is connected end to end to form a closed loop, and a plurality of ribs 5 and microperforated holes are formed in the closed loop. The sandwich block 6 to be pushed out connected to the sandwich layer 3; the lower surface of the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com