A tunnel cellular noise reduction screen

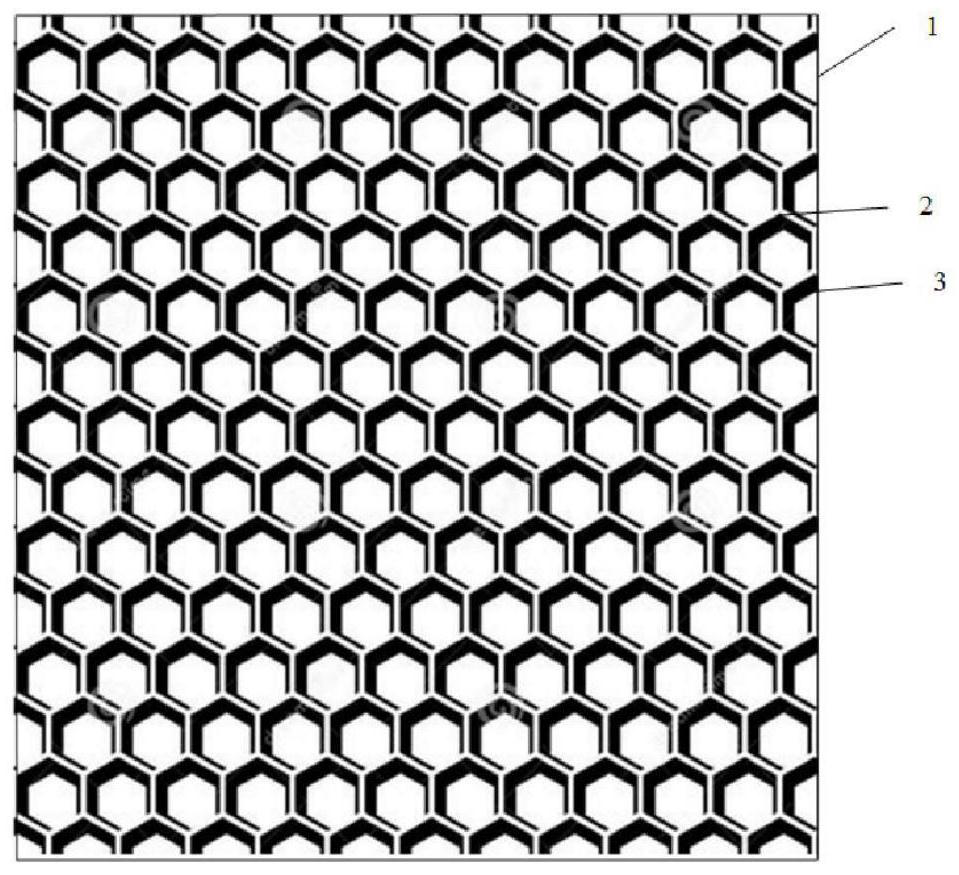

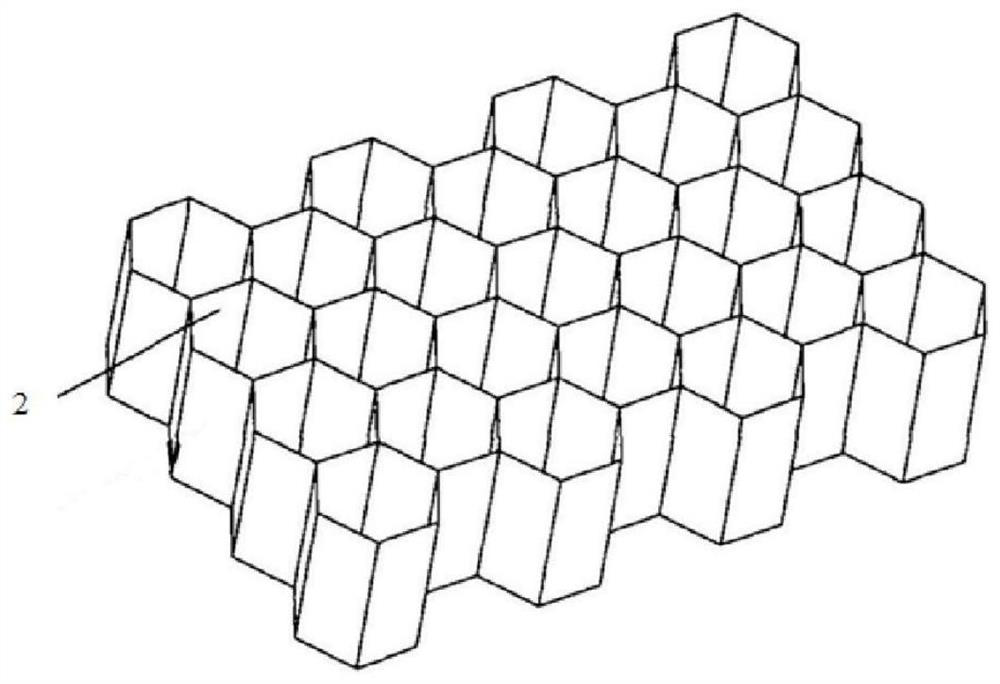

A honeycomb and noise reduction technology, which is applied in noise absorption devices, buildings, analysis of solids using sonic/ultrasonic/infrasonic waves, etc. It can solve the problems of inability to reduce noise and increase the amount of channel noise, and achieve high absorption rate and bubble distribution. Uniform, high absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

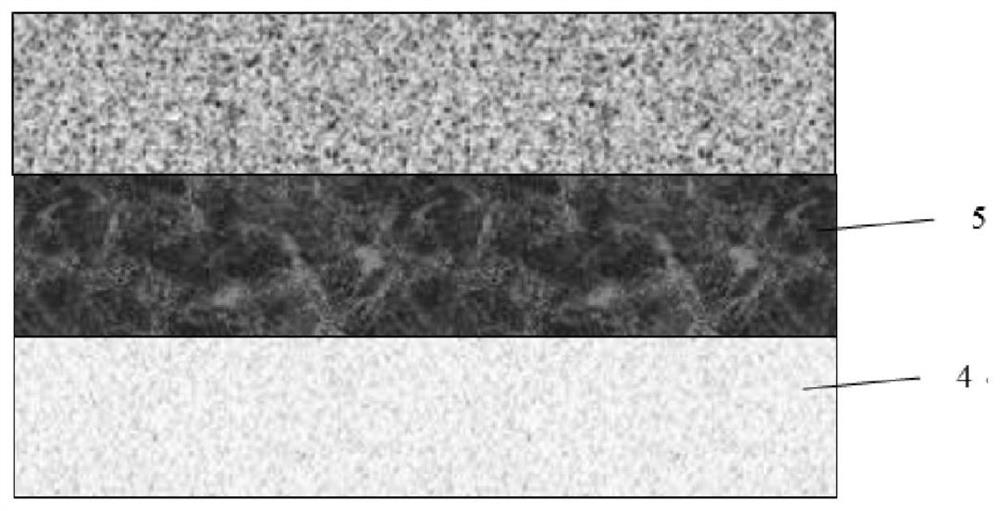

[0038] make 1m 2 The sealing bottom plate is flat, the height of the flute is 6cm, and the height is 6cm, and the length is 3cm. The regular hexagonal plane honeycomb with the same height, the bottom sealing plate is made of 5 layers of carbon fiber cloth, and the honeycomb cylinder is made of two layers, which are assembled into a honeycomb. The sound-absorbing material is rock wool with a thickness of about 0.7cm as the base, and the porous foamed rubber with a thickness of about 0.5cm is adhered (without any filler), the opening rate is 50%, the transition layer is about 0.5cm, and the diameter of the through hole is 0.3cm , through hole density 2 / cm 2 . The average vertical incidence sound absorption coefficient of the whole device is about 0.75, and the effective noise absorption frequency band is 400Hz to 2000Hz with the absorption noise of 15dB as the boundary. 20 dB.

Embodiment 2

[0040] The rock wool substrate in the embodiment 1 is replaced by the carbon fiber wool of 0.5cm, and the carbon fiber wool of the carbon fiber wool sheet through picking or drawing the carbon fiber wool sheet fusion interface surface extends into the second part at least 3mm to form a fusion transition interface layer, carbon fiber The cotton sheet is directly spray-spun into sheets from carbon fiber raw materials with a diameter of 1 micron to 10 microns, and then the interwoven floret feathers are formed by surface picking or hair pulling process, and then carbon fiber cotton sheets are formed by carbonization process, and the carbon fibers on the interface surface are fused. The density of the hair should be at least 50 / cm 2 , the density of floret down feather is at least 5 / cm 2 .

[0041] Under the condition that other settings remain unchanged, the average vertical incidence sound absorption coefficient of the whole device is increased to about 0.9, so that the effecti...

Embodiment 3

[0043] 0.7wt% of hydrotalcite / graphene-like additives and 2wt% of acid anhydride hydrotalcite / aminated carbon black are added to the porous foamed rubber raw material in Example 2 and foamed. Under the ideal test environment, the whole device The average vertical-incidence sound absorption coefficient has been significantly increased to about 0.98, and the effective noise absorption frequency band of absorbing noise of 15 dB is widened to 50 Hz to 3000 Hz. In an ideal laboratory environment, the mixed noise of vertical incidence of 80 dB can absorb 60 Above decibels, the temperature of the continuous incident sound-absorbing material increases, but under the same conditions, compared with the sound-absorbing material of Example 2 without fillers, the noise of the same volume of each frequency is continuously incident, and the temperature is reduced to between 40 and 55 degrees Celsius , it can be seen that the heat dissipation capacity has been significantly improved while the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com