Powder bucket structure

A powder bucket and powder level gauge technology, which is applied in spraying devices, liquid spraying devices, paint spraying rooms, etc., can solve the problems of affecting spraying, troublesome disassembly and assembly of powder suction pipes and plug-in boards, and inconvenient use of powder buckets, and achieves simplification. Easy to operate, easy to use, easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

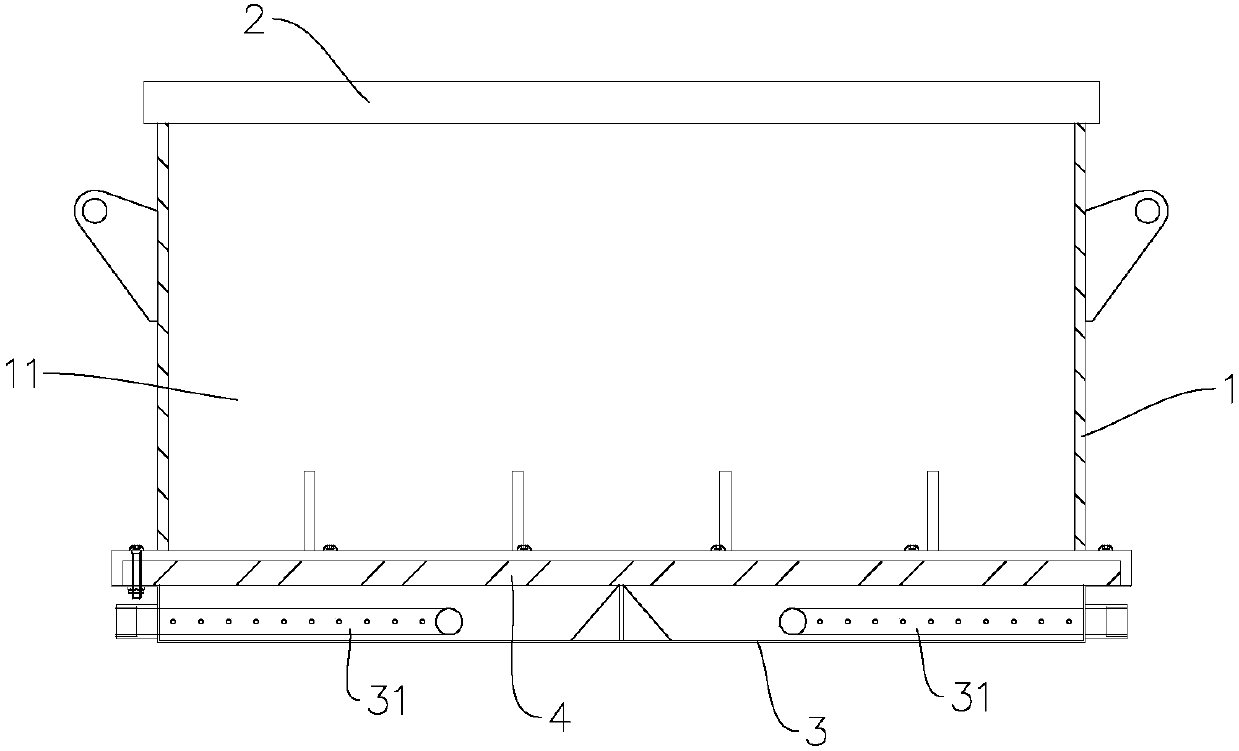

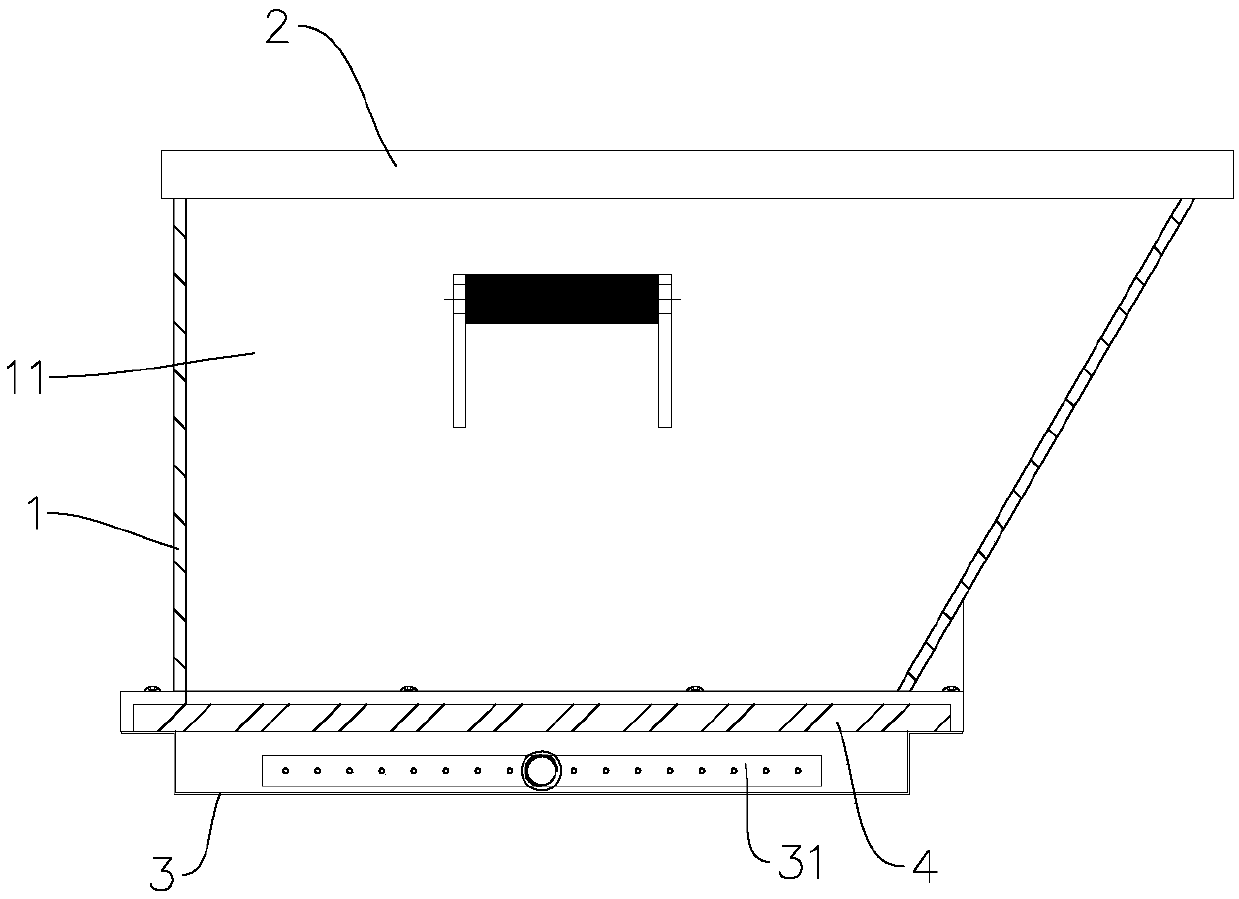

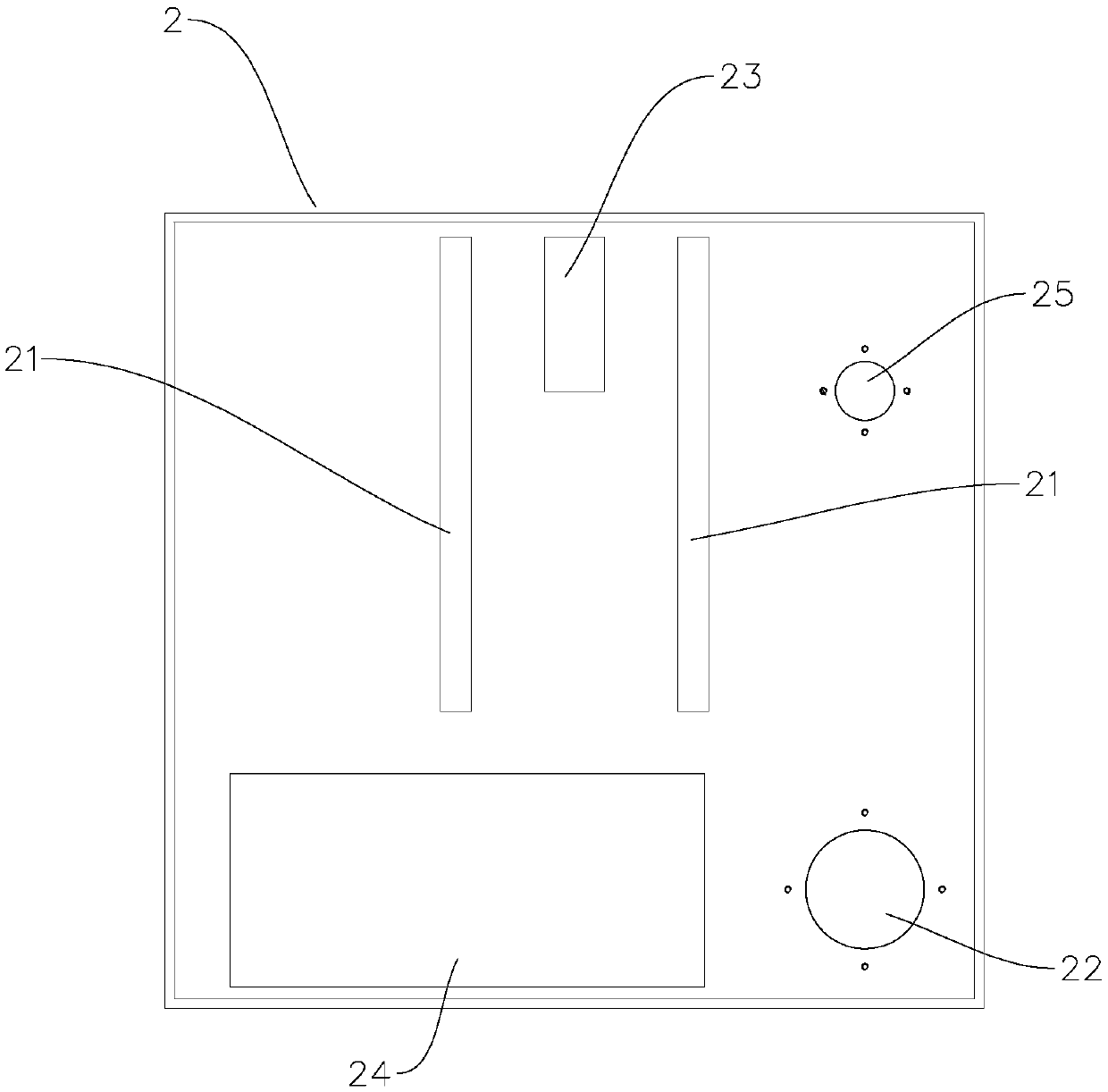

[0017] refer to Figure 1 ~ Figure 3 , the present invention is a powder bucket structure, including a powder bucket main body 1 and a powder bucket cover 2, an accommodating cavity 11 capable of accommodating powder is opened on the upper end surface of the powder bucket main body 1, and the powder bucket cover 2 is closed on the powder bucket main body 1 and can close the accommodating cavity 11 to avoid powder overflow. The powder bucket cover 2 is provided with an installation channel 21 for inserting a powder suction pipe, and when the powder suction pipe is inserted in the installation channel 21, the upper opening of the installation channel 21 can be closed. The upper end opening of the installation channel 21 can be closed by using the powder suction pipe, without the need to set up a plate or the like, thereby simplifying the structure of the present invention, the powder suction pipe is more convenient to disassemble, simplifies the operation, and facilitates the us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com