Sand blasting nozzle

A technology of sandblasting nozzles and sand bins, which is applied in the direction of spray guns, explosion generating devices, abrasives, etc., can solve the problems of poor sandblasting effect, narrow distribution area, low efficiency, etc., achieve uniform surface treatment effect, uniform and stable spraying, The effect of increasing the spray area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

[0016] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

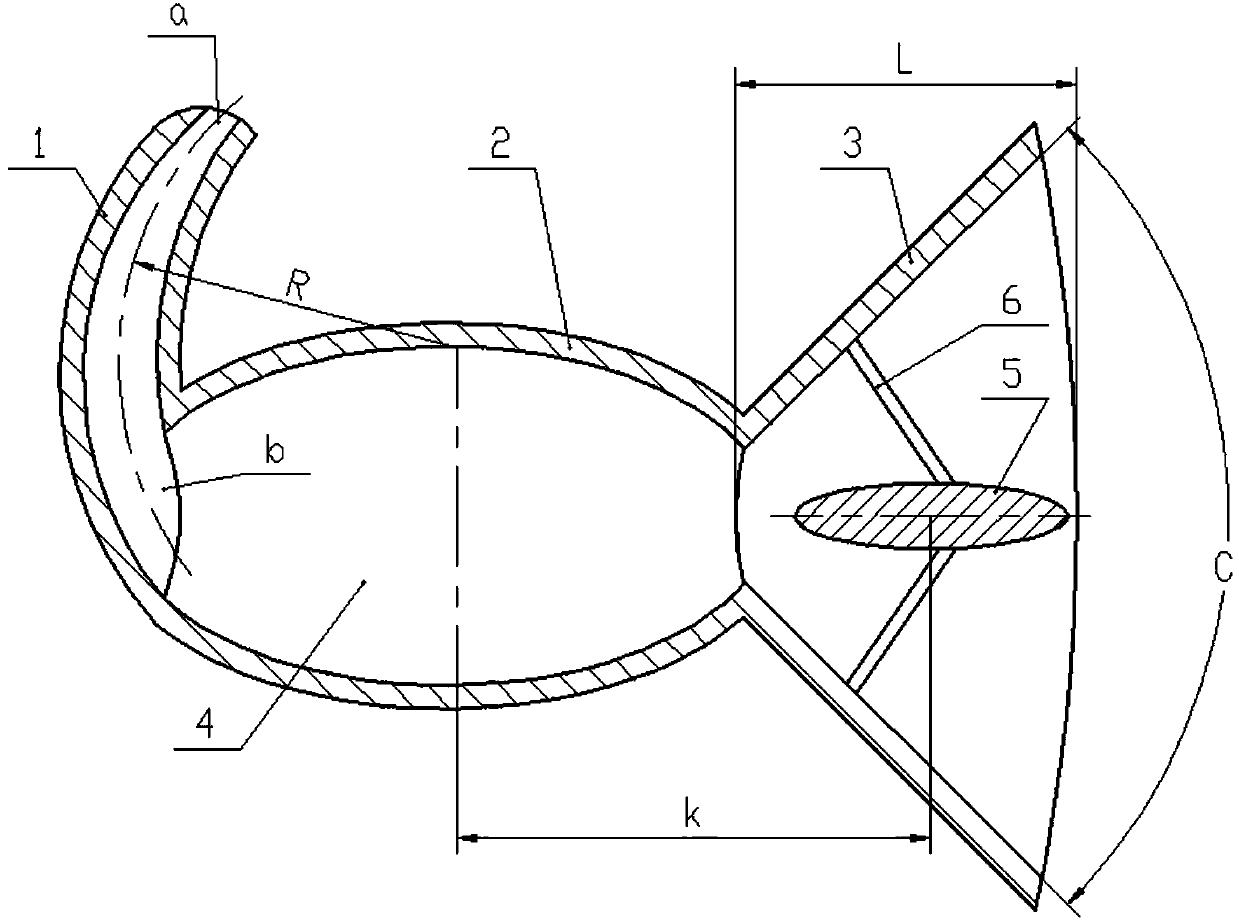

[0017] Such as figure 1 As shown, a sandblasting nozzle includes a feed pipe 1, a sand holding bin 2, and a spraying part 3. The sand holding bin 2 has an ellipsoidal cavity 4 and one end of the long axis of the cavity 4 has a The inlet, the feed pipe 1 is a circular arc pipe section, the outlet of the feed pipe 1 is connected to the inlet of the sand container 2 cavity, and the arc convex direction of the feed pipe 1 is as long as the cavity 4 The protruding ends in the axial direction have the same protruding direction, and an outlet is provided at the other end of the long axis of the cavity 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com