Anti-release medical cover mold and mold pressing equipment

A mold and demoulding technology, which is applied in the field of reverse demoulding medical cover molds and molding equipment, can solve the problems of failing to meet medical standards and cannot be widely promoted, and achieve the effects of good effect, rapid demoulding and high efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

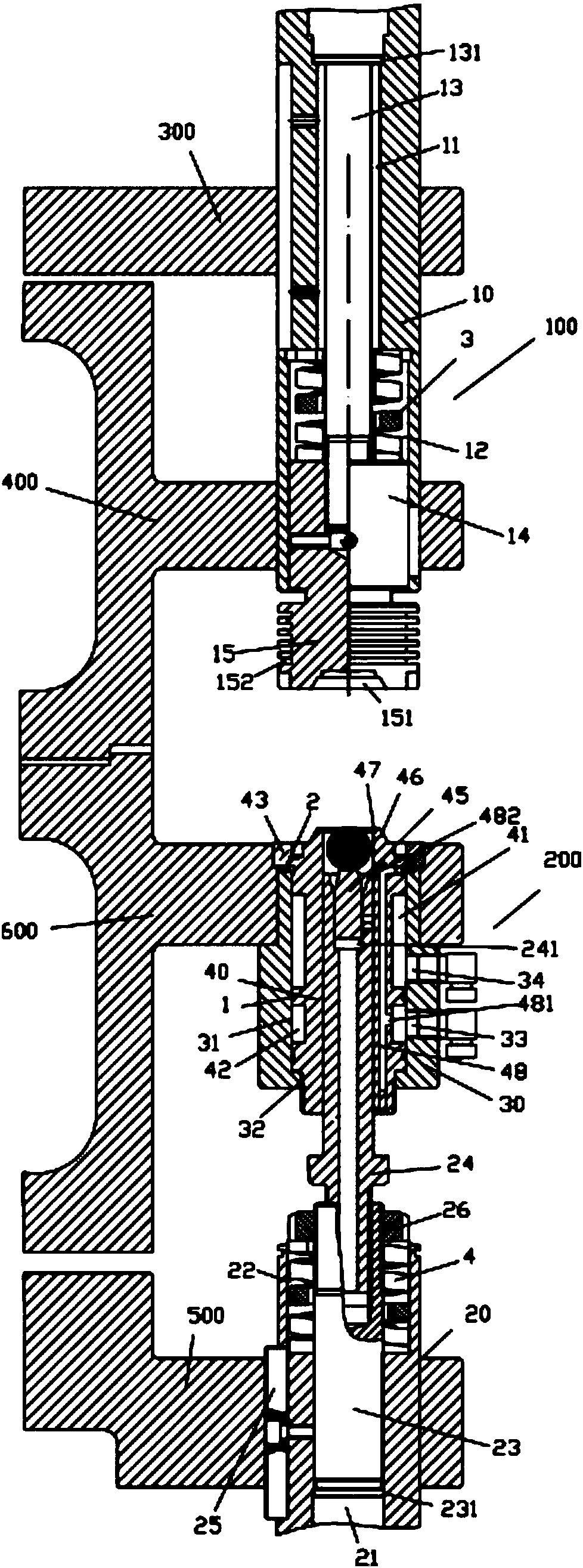

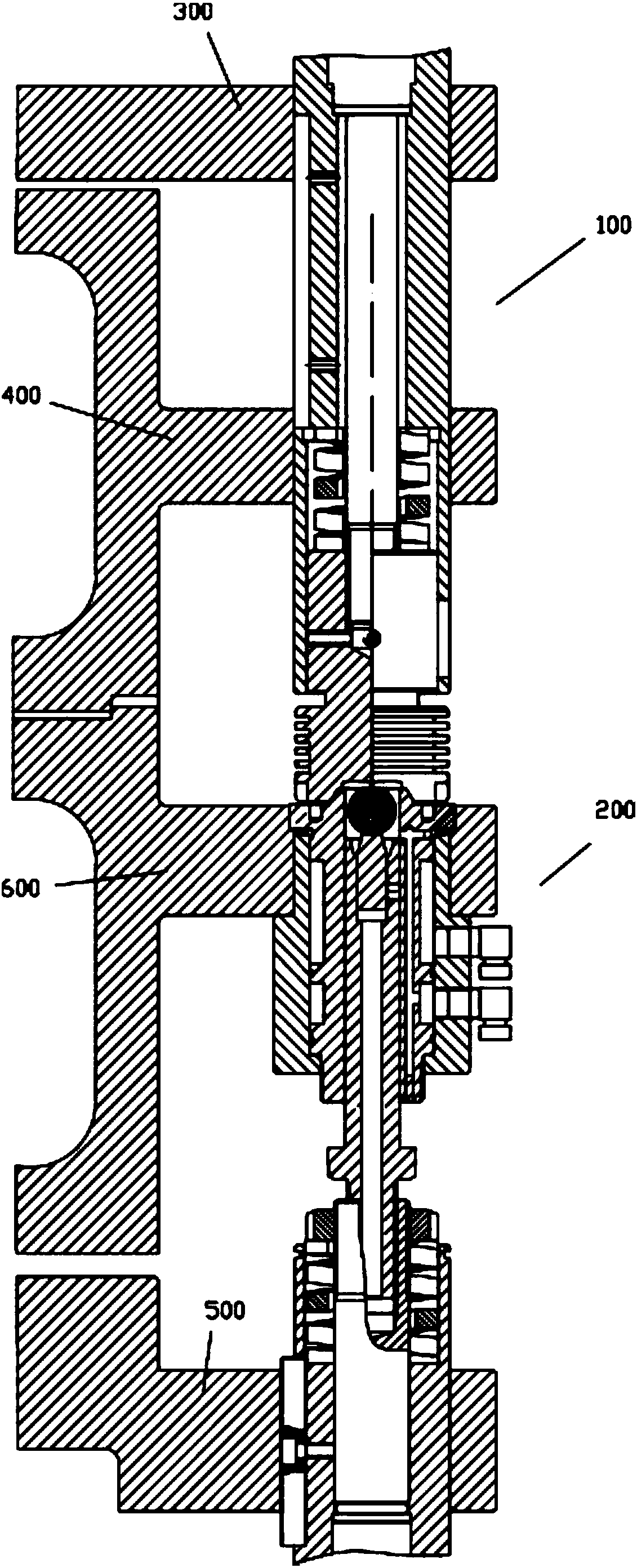

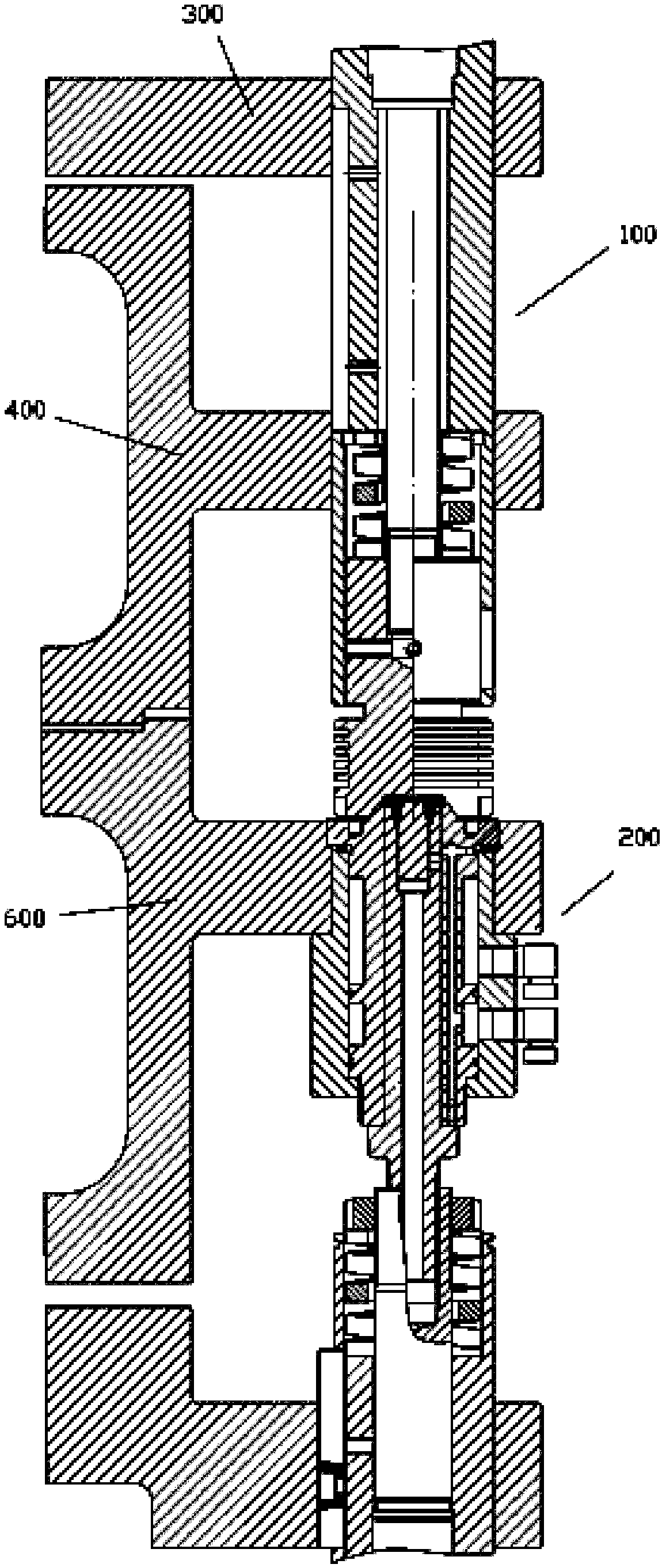

[0025] Examples, see e.g. Figure 1 to Figure 7 As shown, a kind of anti-demolding medical cover mold includes an upper mold mechanism 100 and a lower mold mechanism 200. The upper mold mechanism 100 includes an upper moving sleeve 10, and the middle part of the upper moving sleeve 10 is a stepped through hole 11, and the step The diameter of the upper hole section of the through hole 11 is greater than the diameter of the lower hole section, and the stepped through hole 11 communicates with the fixed socket 12 provided in the middle of the lower end of the upper moving sleeve 10, and the diameter of the fixed socket 12 is larger than the bottom of the stepped through hole 11 The diameter of the hole section, the upper push rod 13 is inserted into the lower hole section of the stepped through hole 11, and the radially extending edge 131 that the top outer wall of the upper push rod 13 has is in the upper hole section of the stepped through hole 11 and pressed against On the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com