Boxing device used for batteries

A battery and boxing technology, applied in packaging, transportation and packaging, single objects, etc., can solve problems such as low efficiency, easy accumulation, and unable to produce in a normal and orderly manner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Attached below Figure 1 to Figure 15 The present invention is further described.

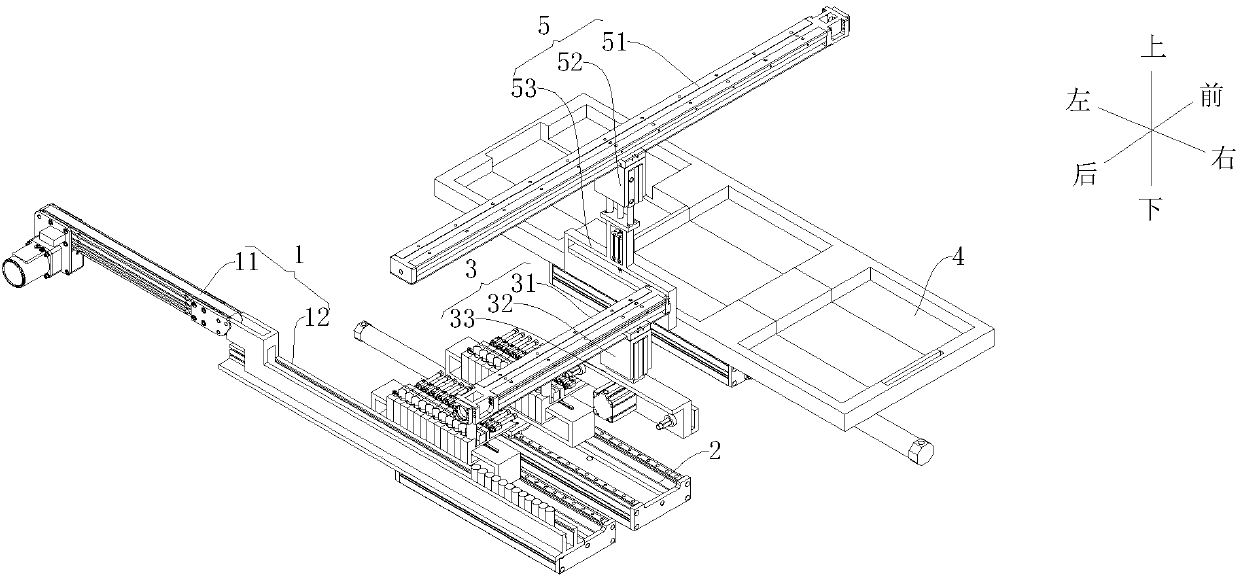

[0031] A boxing device for batteries according to the present invention, such as figure 1 As shown, the boxing device is suitable for being located at the downstream of the filming machine for the battery casing, and the boxing device includes: a material guide device 1, a spacing device 2, a first material moving device 3, a boxing device Platform 4 and the second material shifting device 5.

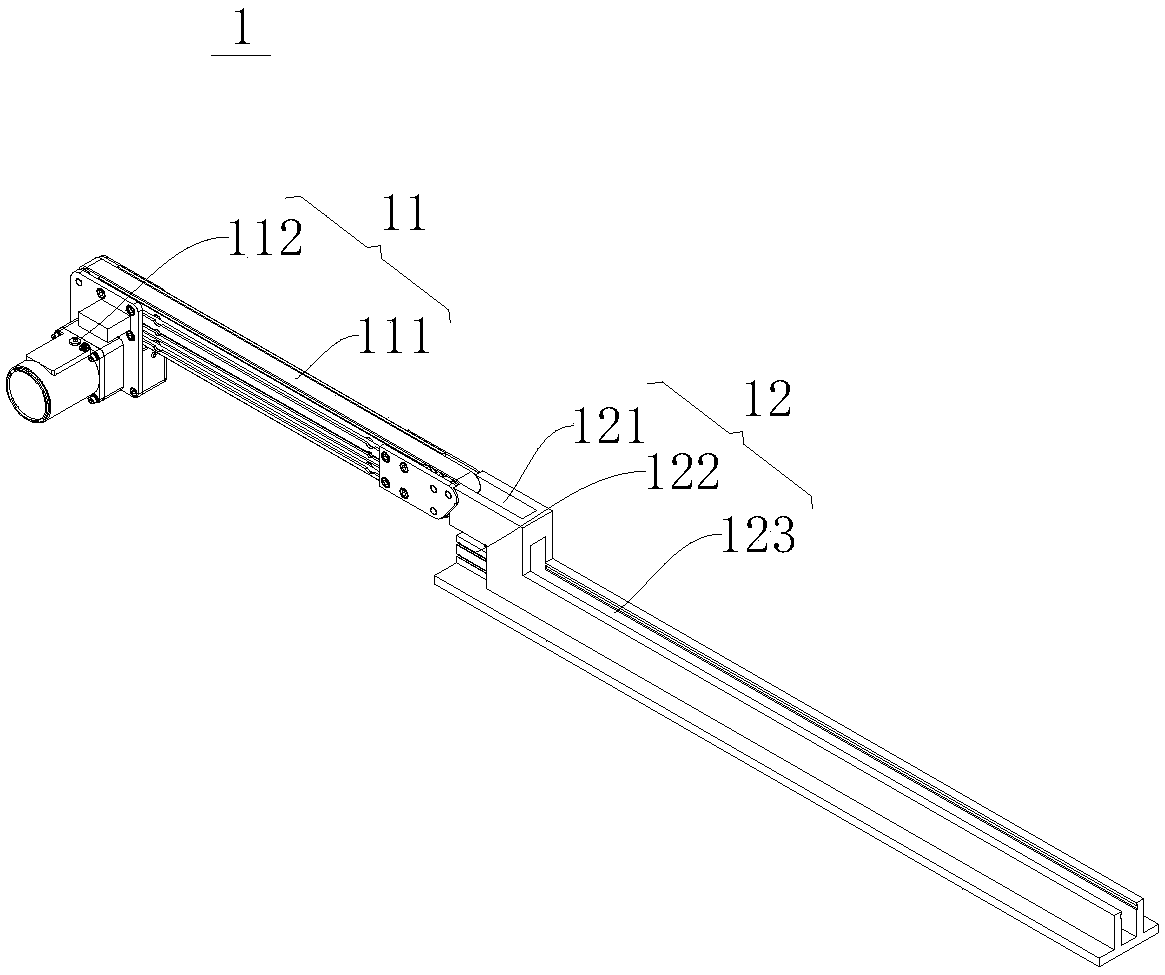

[0032] Material guiding device 1, described material guiding device 1 comprises conveying device 11 and the arrangement device 12 that can arrange a plurality of batteries side by side, and described conveying device 11 is suitable for being arranged at the lower end of the material discharge port of described coating machine so that The batteries at the feeding port are transported to the arrangement device 12;

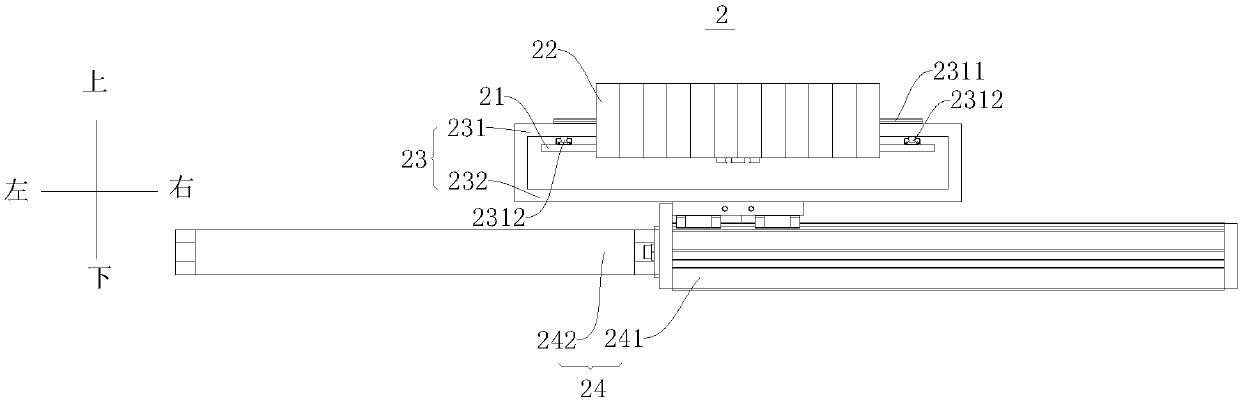

[0033] Spacer 2, such as Figure 3 ~ Figure 7 As shown, it includes: a movable d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com