A handling robot

A technology for handling robots and end faces, which is applied in the field of handling robots. It can solve problems such as shortening the service life of robots, shifting the center of gravity, and dumping robots, and achieves the effects of adding an overweight alarm function, avoiding overload work, and improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

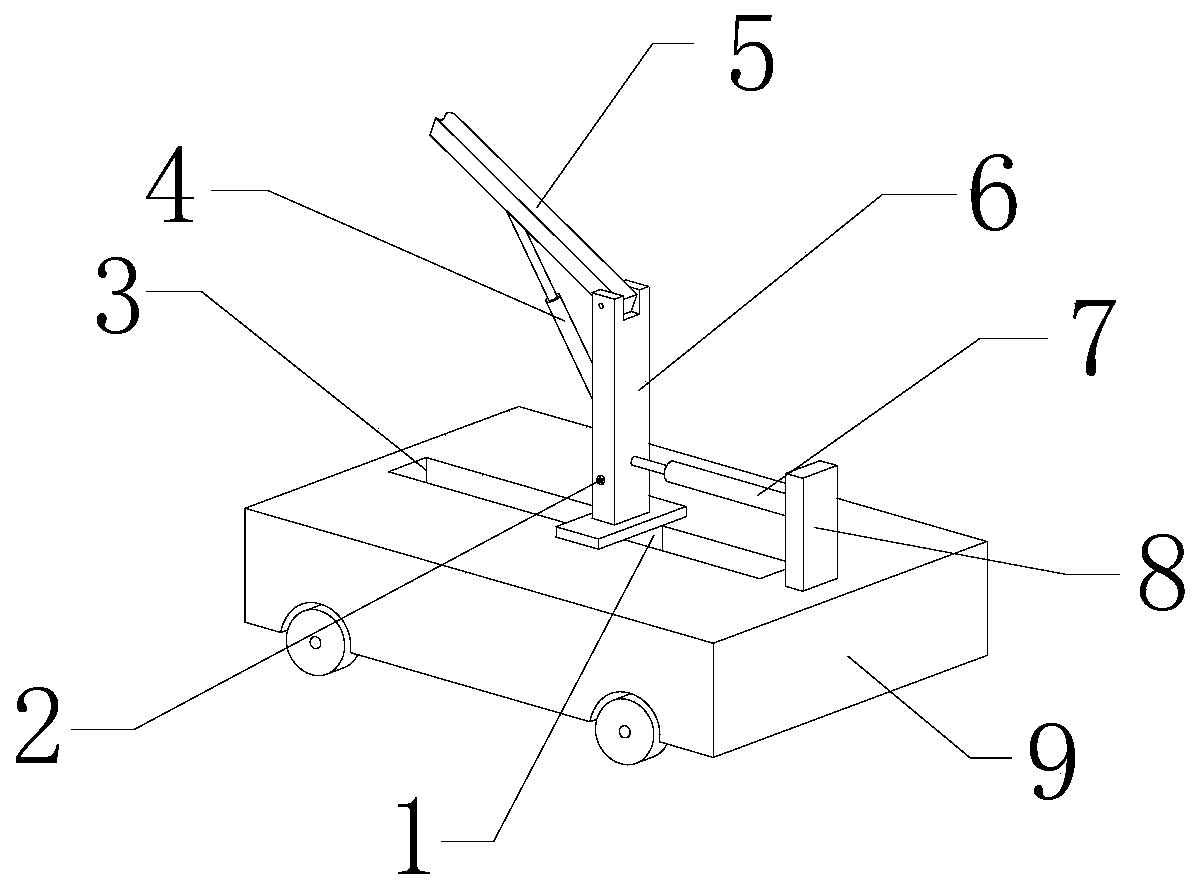

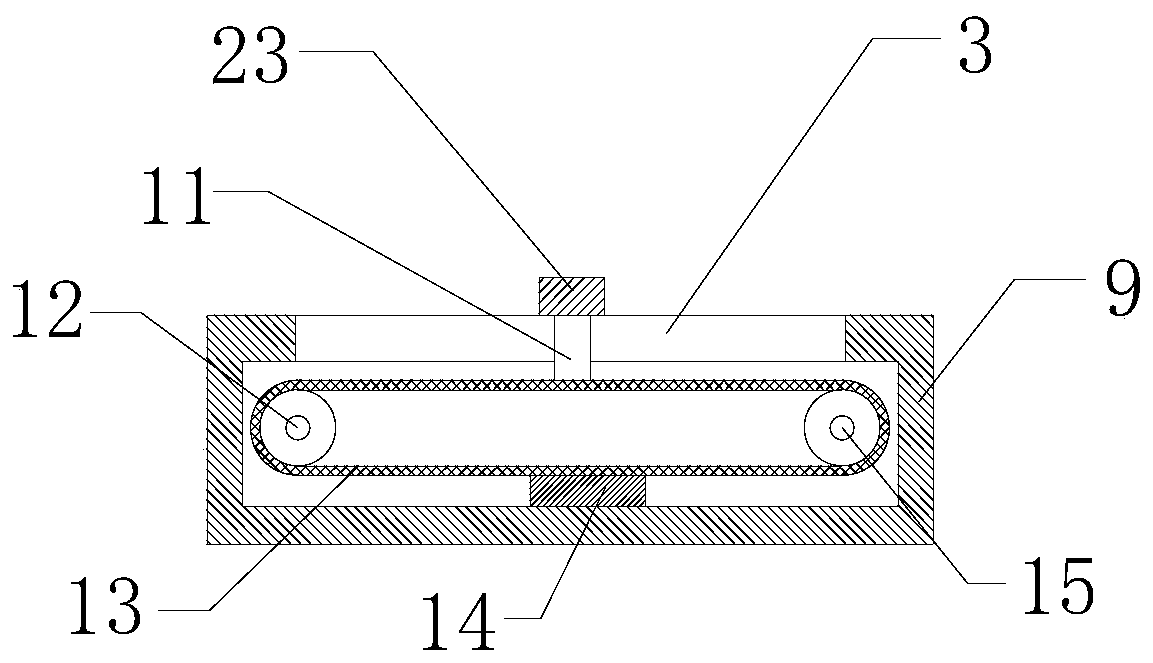

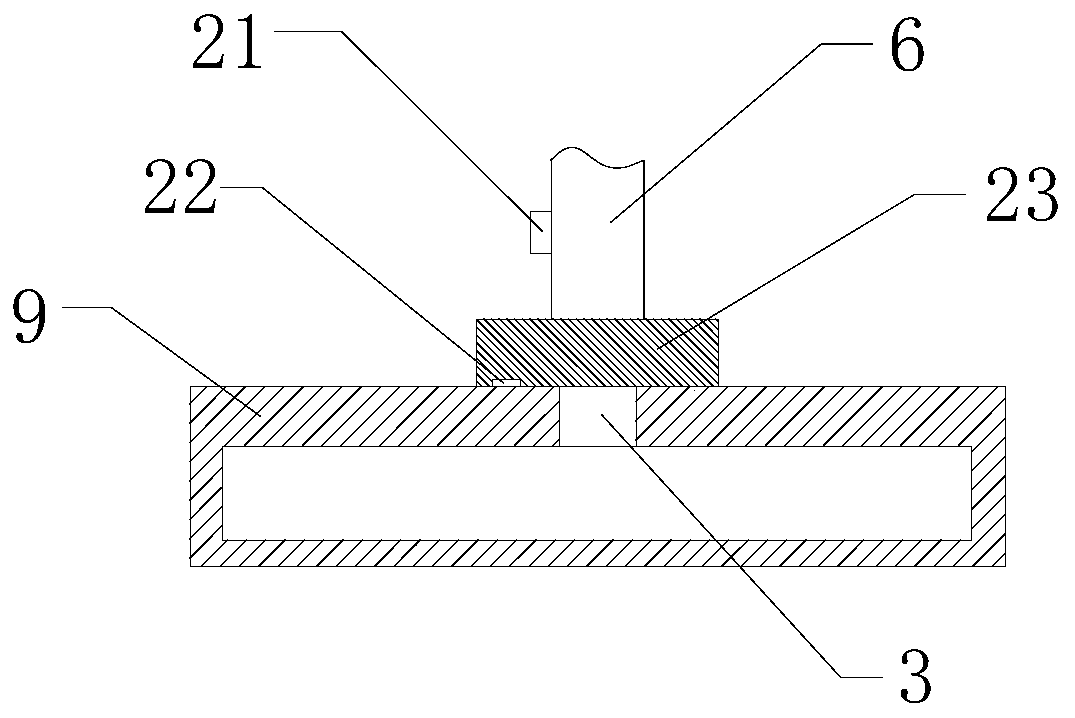

[0024] Specific implementation method: when in use, the user uses the clamp to clamp the goods to be transported, and the angle between the movable arm 5 and the fixed arm 6 can be adjusted by adjusting the length of the hydraulic rod 4 to realize the lifting or falling of the goods. The expansion or contraction of the telescopic rod 7 and the electric telescopic rod 7 drives the fixed arm 6 to move, and the fixed arm 6 drives the square connecting rod 11 to slide in the chute 3 through the slide plate 23, and the square connecting rod 11 drives the transmission belt 13 to surround the roller 12 Moving with the roller 2 15, the transmission belt 13 drives the counterweight 14 to move opposite to the square connecting rod 11, so as to achieve the purpose of balancing the center of gravity at any time, and solve the problem of the center of gravity when the original handling robot is doing telescopic clamping and handling operations. Offset can easily cause the robot to topple an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com