A preparation method of a polymer organic ligand, a preparation method of a polymer metal-organic framework, an ion separation membrane and a preparation method thereof

A metal-organic framework and ion separation technology, which is applied in the preparation of polymer metal-organic frameworks, ion separation membranes and their preparation, and the preparation of polymer organic ligands, can solve the problem of long-term stability of polymer metal-organic frameworks that needs to be improved and other problems, to achieve the effect of simple and effective construction, simplified preparation, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Preparation of polymeric organic ligands:

[0059] Diethyl 2,5-dihydroxyterephthalate (1.2 g, 4.7 mmol), 1,10-dibromodecane (4.7 mmol) and potassium carbonate (2.6 g, 19.0 mmol) were mixed and added to 33 mL A suspension was formed in DMSO, and the reaction was stirred at 100 °C for 24 h.

[0060] After the above reaction system was cooled down to room temperature, 50 mL of water was added to the reaction system, and the obtained reaction product was separated by centrifugation, and then the product was washed three times with methanol and acetone, each time with 35 mL of detergent.

[0061] The products of the above steps were collected by centrifugation, and dried overnight at 60°C. The obtained dry product (1.0g) was added to a total of 30mL of a mixed solution of water and DMSO with a volume ratio of 1:1, and 4.0g of KOH was added, and the mixed solution was heated to 80°C and reacted for 8h to obtain a clear solution until.

[0062] The resulting clear solution ...

Embodiment 2

[0075] The polymer organic ligand, polymer metal organic framework and ion separation membrane were prepared according to the method described in Example 1, the difference from Example 1 was that 1,9-dibromononane was used.

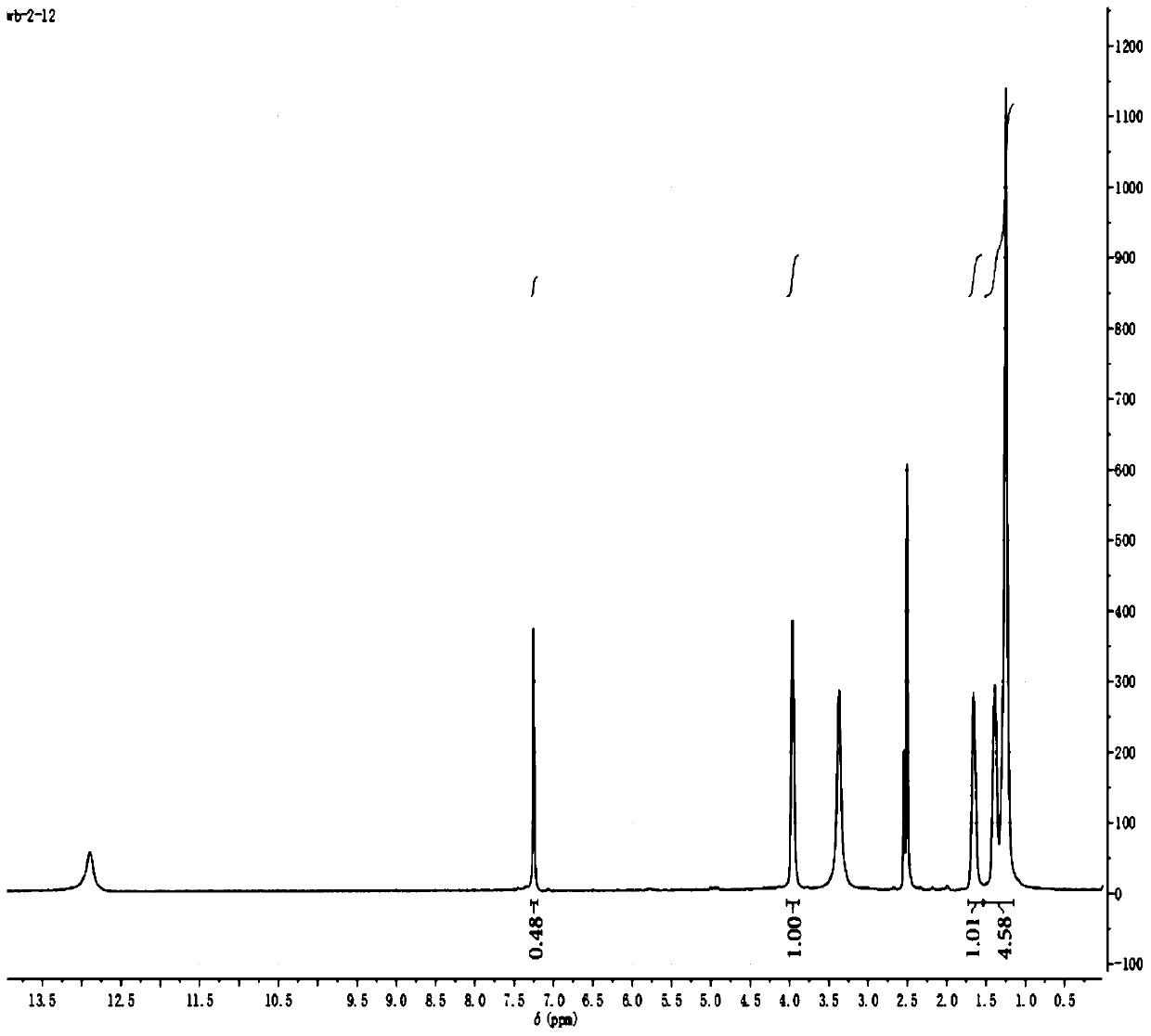

[0076] The nuclear magnetic resonance detection result of the macromolecular organic ligand prepared in Example 2 of the present invention is as follows image 3 shown. Depend on image 3 It can be seen that there is an obvious strong peak of carboxyl hydroxyl hydrogen near 12.8ppm, indicating that the hydrolysis reaction is relatively complete, the original carboxylate has been hydrolyzed into carboxylic acid, and the polymer organic ligand can be used for coordination. At the same time, near 7.26ppm, there is a characteristic peak of methylene group shifted due to the connection with oxygen atom, indicating that the original hydroxyl group has been replaced by an alkoxy group. From this, it can be determined that the synthesis of polymeric organic lig...

Embodiment 3

[0081] The polymer organic ligand, polymer metal organic framework and ion separation membrane were prepared according to the method described in Example 1, the difference from Example 1 was that 1,11-dibromoundecane was used.

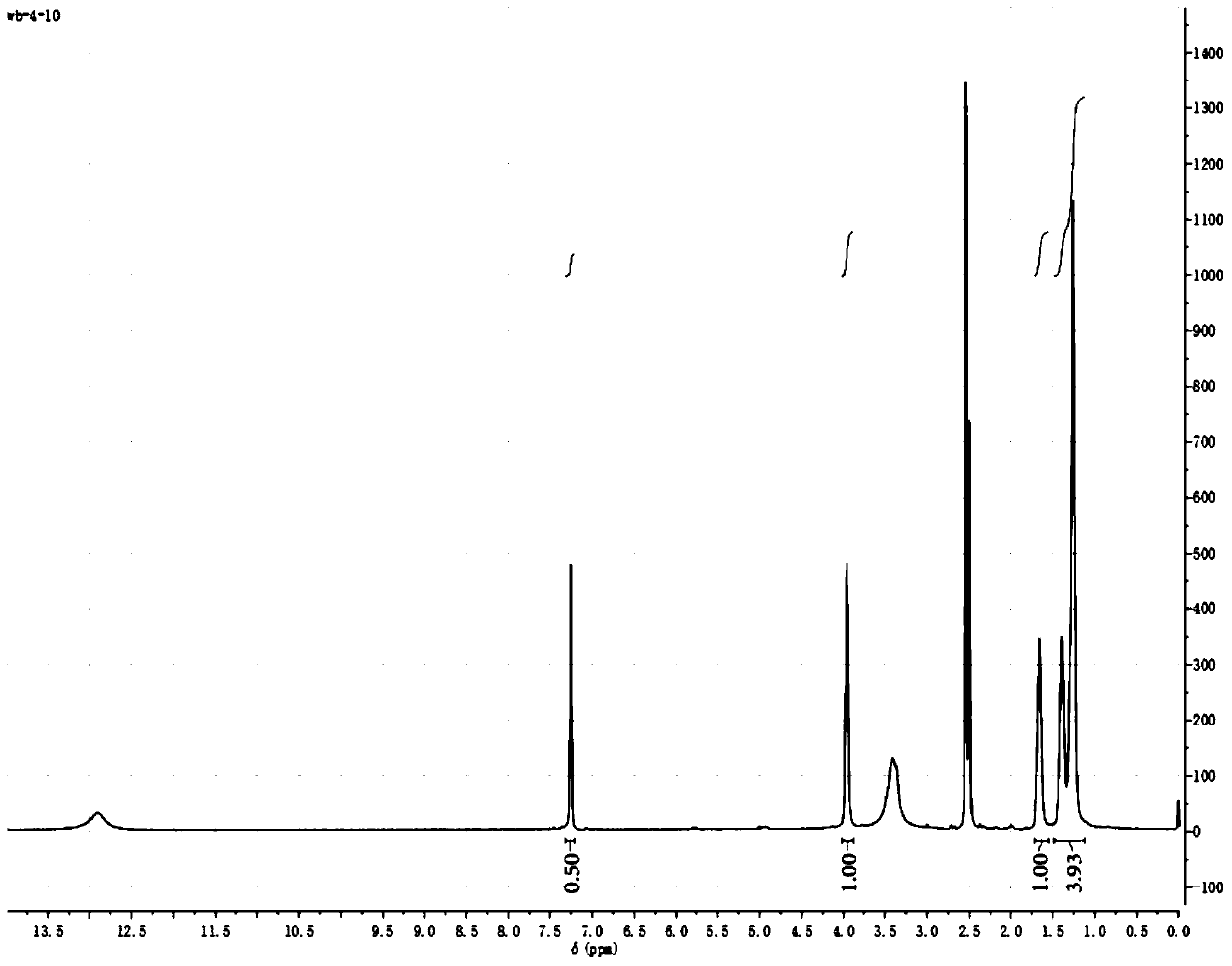

[0082] The nuclear magnetic resonance detection result of the macromolecular organic ligand prepared in Example 3 of the present invention is as follows Figure 4 shown. Depend on Figure 4 It can be seen that there is an obvious strong peak of carboxyl hydroxyl hydrogen near 12.8ppm, indicating that the hydrolysis reaction is relatively complete, the original carboxylate has been hydrolyzed into carboxylic acid, and the polymer organic ligand can be used for coordination. At the same time, near 7.26ppm, there is a characteristic peak of methylene group shifted due to the connection with oxygen atom, indicating that the original hydroxyl group has been replaced by an alkoxy group. From this, it can be determined that the synthesis of polymeric organi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com