Novel ramie decorticator

A hemp peeling machine and ramie technology, applied in mechanical processing, fiber mechanical separation, textiles and papermaking, etc., can solve the problems of low efficiency of ramie peeling, achieve strong skin and bone separation ability, high peeling rate, fresh stem peeling high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

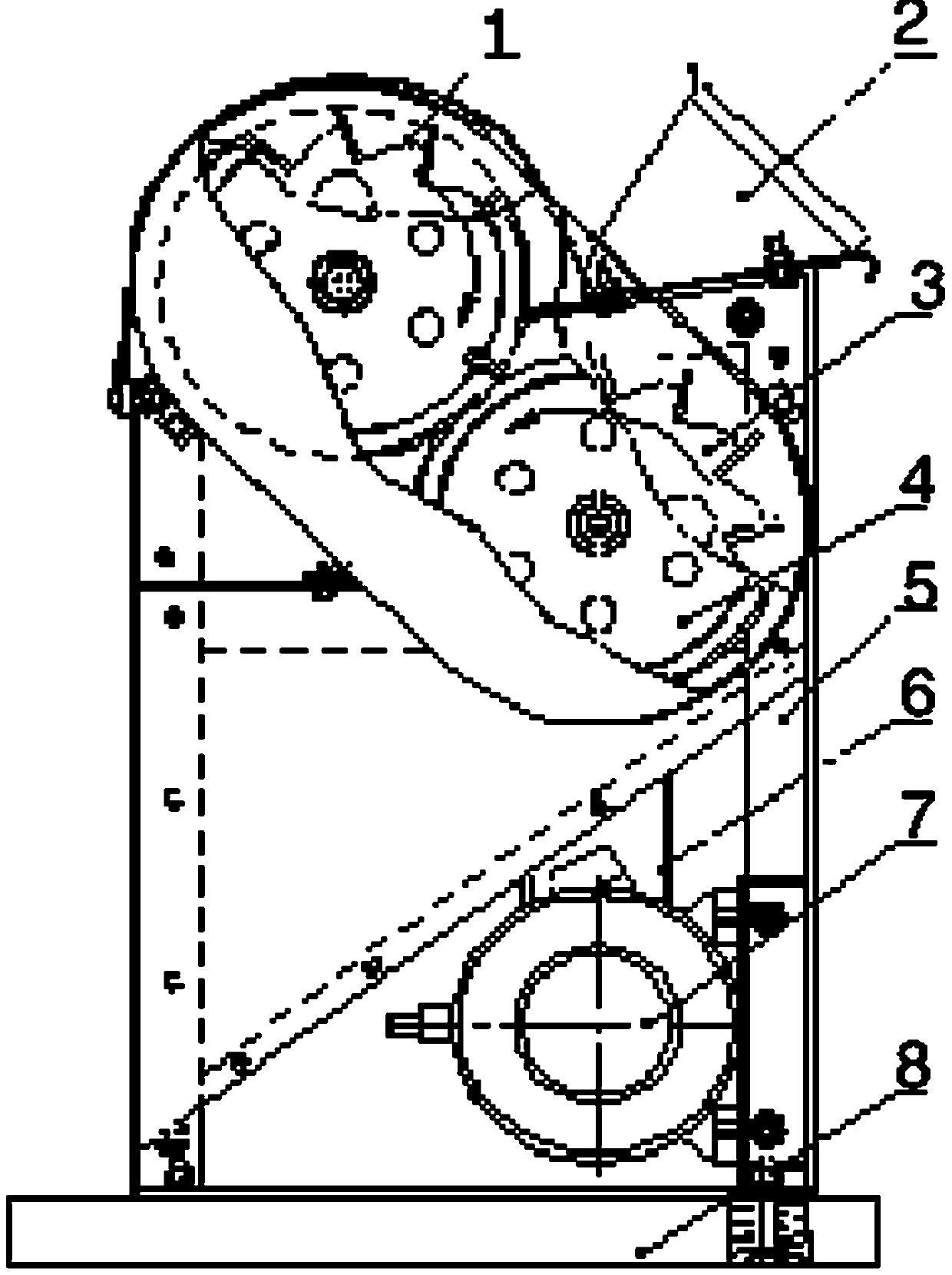

[0014] exist figure 1 Among them, it includes auxiliary detachment cylinder, feeding hopper, main detachment cylinder, meshing gear, frame, belt drive, motor, frame base, and is characterized in that: when the ramie detachment machine is working, the motor (7) is driven by the belt ( 6) Drive the driving wheel to rotate, and drive the main roller to rotate through meshing; the operator holds the base of the fresh ramie stem, and feeds the part into the high-speed rotating main roller (3) and auxiliary roller through the feeding hopper (2). Between the hemp rollers (1), under the continuous scraping action of the hemp peeling roller, the xylem and epidermis of the hemp stem are crushed into debris and thrown out of the machine. At this time, the stripped fibers are reversely drawn out to complete the part peeling; then turn around and peel the base, that is, complete a peeling process.

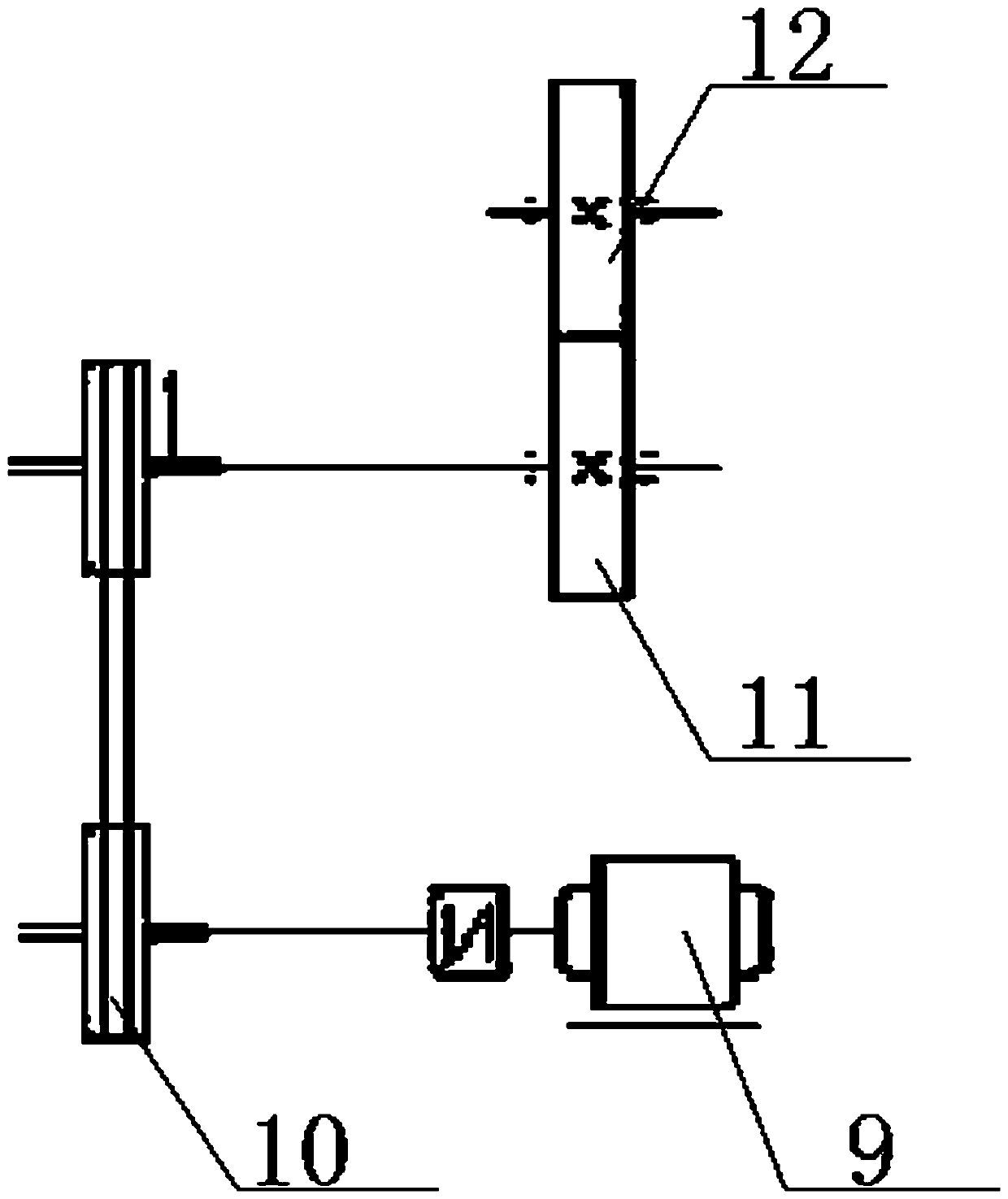

[0015] exist figure 2 Among them, it includes a motor, a V-belt pulley, a driving wheel,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap