A new type of anti-drop device for bridge construction

A bridge construction and anti-drop technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of short service life of anti-fall devices, small maximum bearing capacity of anti-fall devices, and poor anti-fall effects. Achieve the effect of preventing damage, prolonging service life and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

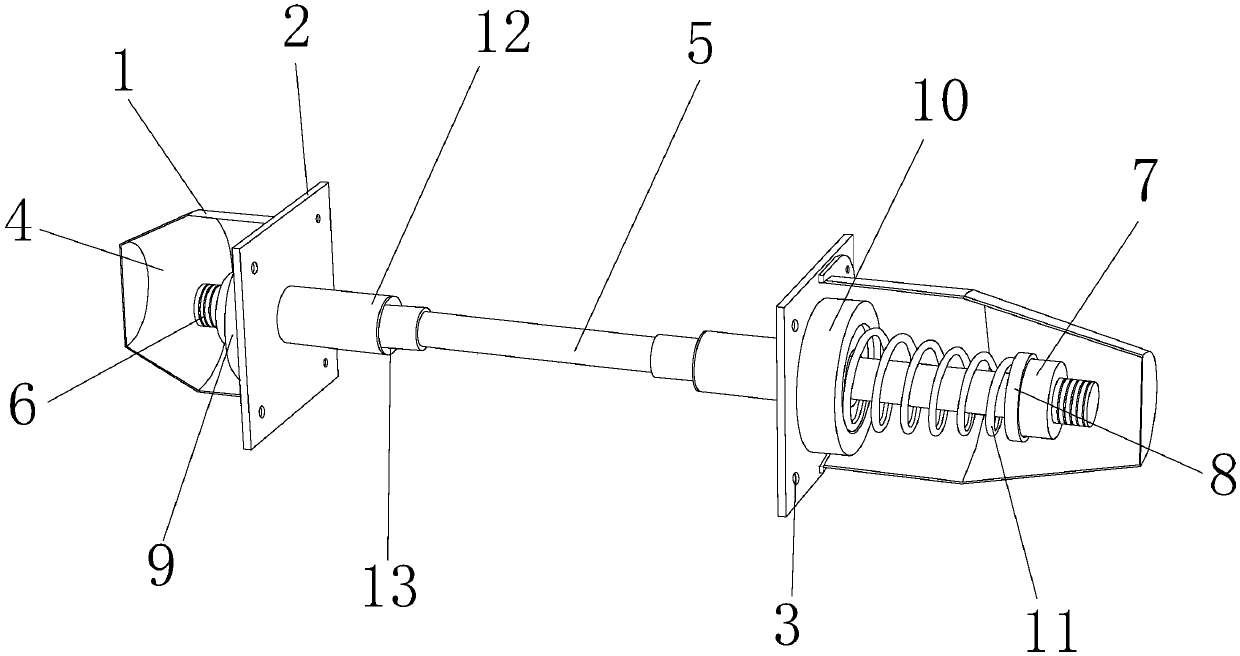

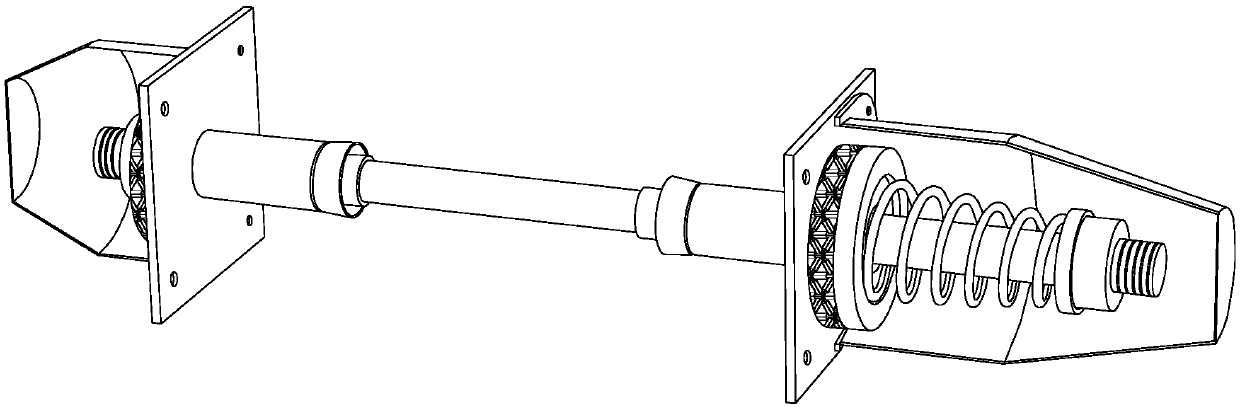

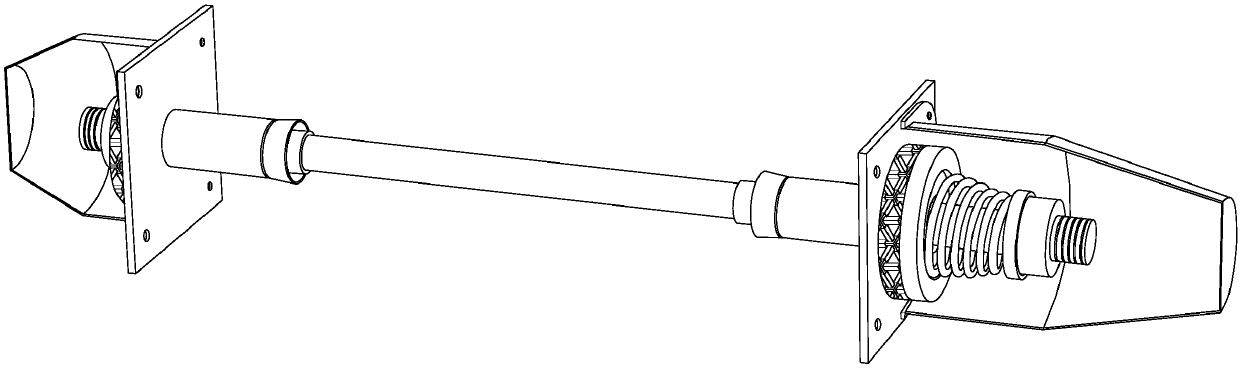

[0034] see Figure 1-Figure 7 , the present invention provides a new type of technical solution for bridge construction fall prevention device: its structure includes a protective shell cover 1, a stopper plate 2, a fixing screw hole 3, a telescoping limited cavity 4, a deformable sliding rod 5, a fixing thread 6, Set nut 7, welding gasket 8, starting welding ring 9, terminal welding ring 10, strong spring 11, fixed sleeve 12, telescopic movable joint 13, the protective shell cover 1 and the stop plate 2 are equipped with two , the protective cover 1 is respectively arranged on the outer surface of the stop plate 2, the port of the protective cover 1 is provided with a flange, and the stop plate 2 is rectangular and equidistantly provided with four fixing screw holes 3 , the fixing screw hole 3 and the baffle plate 2 are integrally formed, and the protective shell 1 is connected with the baffle plate 2 in a vertical or vertical shape through the cooperation of the flange plate...

Embodiment 2

[0038] see Figure 1-Figure 12 , the present invention provides a new type of technical solution for bridge construction fall prevention device: its structure includes a protective shell cover 1, a stopper plate 2, a fixing screw hole 3, a telescoping limited cavity 4, a deformable sliding rod 5, a fixing thread 6, Set nut 7, welding gasket 8, starting welding ring 9, terminal welding ring 10, strong spring 11, fixed sleeve 12, telescopic movable joint 13, the protective shell cover 1 and the stop plate 2 are equipped with two , the protective cover 1 is respectively arranged on the outer surface of the stop plate 2, the port of the protective cover 1 is provided with a flange, and the stop plate 2 is rectangular and equidistantly provided with four fixing screw holes 3 , the fixing screw hole 3 and the baffle plate 2 are integrally formed, and the protective shell 1 is connected with the baffle plate 2 in a vertical or vertical shape through the cooperation of the flange plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com