Method for bonding and reinforcing of partition wall through dry method

A technology of bonding and partitioning, applied in the direction of walls, building maintenance, building components, etc., can solve the problems of difficult to guarantee the quality of prefabricated partition walls, unsatisfactory safety reliability and durability stability, and achieve stable bonding quality And reliable, the effect of restraining the displacement and deformation of the partition wall

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

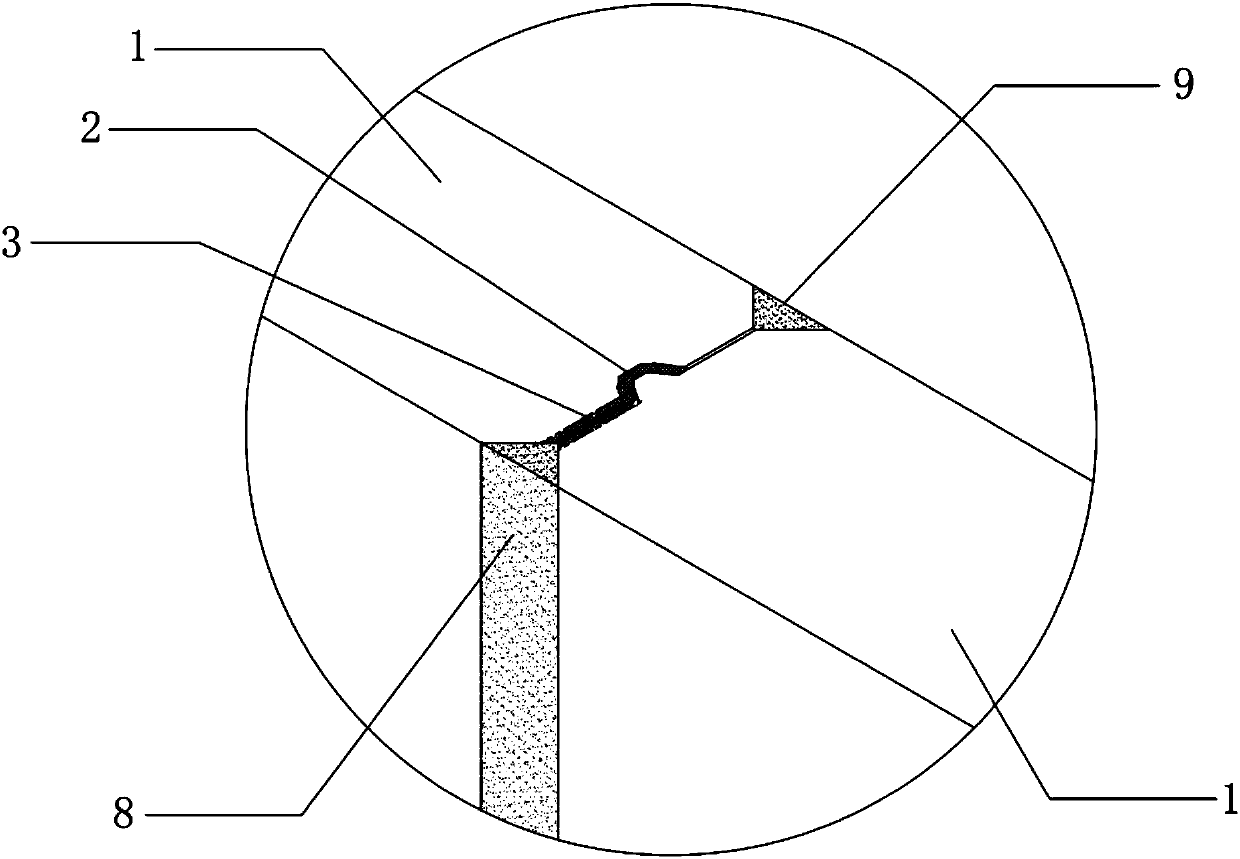

[0042] See attached figure 1 The method for dry-bonding a partition wall provided in this embodiment comprises the following steps:

[0043] (1) Prefabricated wallboard 1, adhesive 2, and bonding member 4 are prepared;

[0044] (2) Splicing several prefabricated wall panels 1 into a partition wall one by one with temporary topping members such as soil wedges in advance;

[0045] (3) Open the perfusion holes 3 for pouring the special adhesive 2 at a certain interval along the partition wall joint; Stuffing into the cementing member 4 for cooperating with the special adhesive 2 for cementing;

[0046] (4) In the way of grouting, pour the inside of the hole 3 into the splicing joint, and fill in the special adhesive 2 in the position of the cementing member 4 for cementation;

[0047] (5) After curing, take out the jacking fixtures used for temporary jacking;

[0048] (6) Fill the gaps that have not been cemented in the joints of the partition wall, and the surface recesses 9...

Embodiment 2

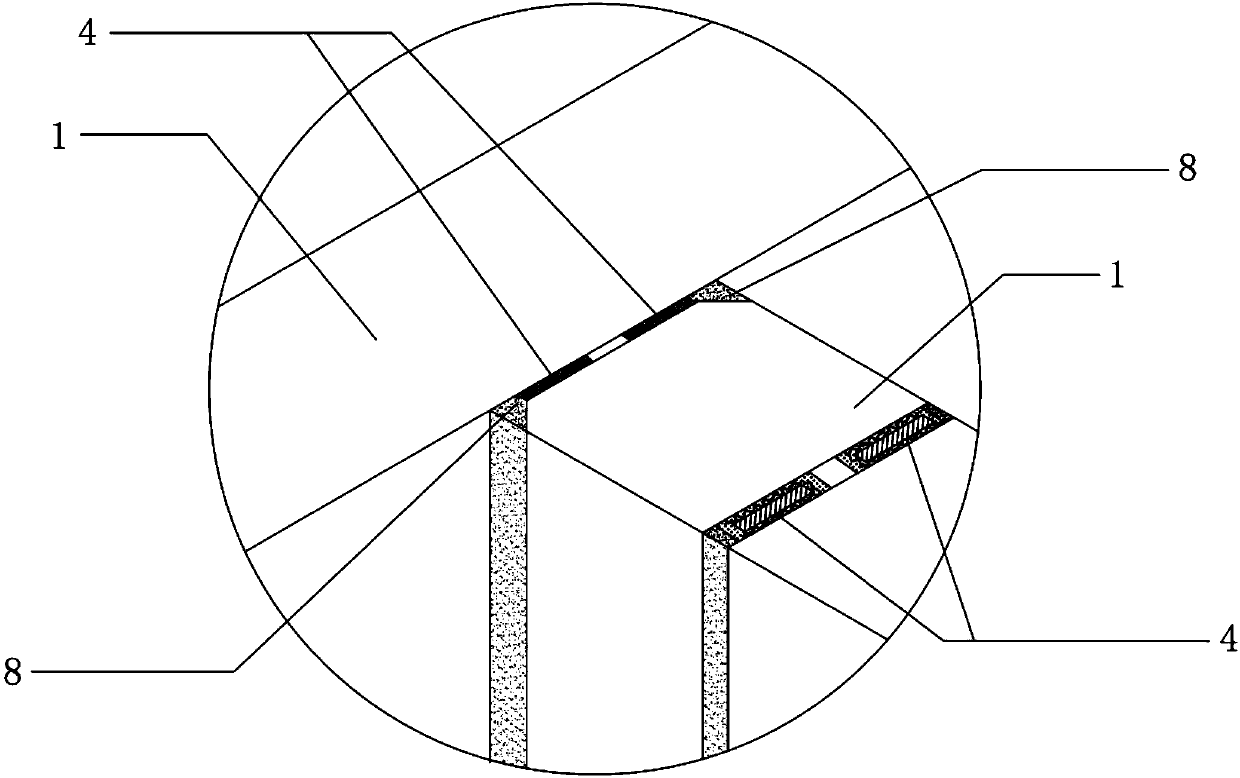

[0060] See attached figure 2 , this embodiment is basically the same as Embodiment 1.

[0061] In the construction method of the dry-work cemented partition wall in this embodiment, the partition wall is of L-shaped or T-shaped structure.

[0062] (1) Prefabricated wallboard 1, adhesive 2, and bonding member 4 are prepared;

[0063] (2) Splicing several prefabricated wall panels 1 into a partition wall one by one with temporary topping members such as soil wedges in advance;

[0064] (3) Open the perfusion holes 3 for pouring the special adhesive 2 at a certain interval along the partition wall joint; Stuffing into the cementing member 4 for cooperating with the special adhesive 2 for cementing;

[0065] (4) In the way of grouting, pour the inside of the hole 3 into the splicing joint, and fill in the special adhesive 2 in the position of the cementing member 4 for cementation;

[0066] (5) After curing, take out the jacking fixtures used for temporary jacking;

[0067] ...

Embodiment 3

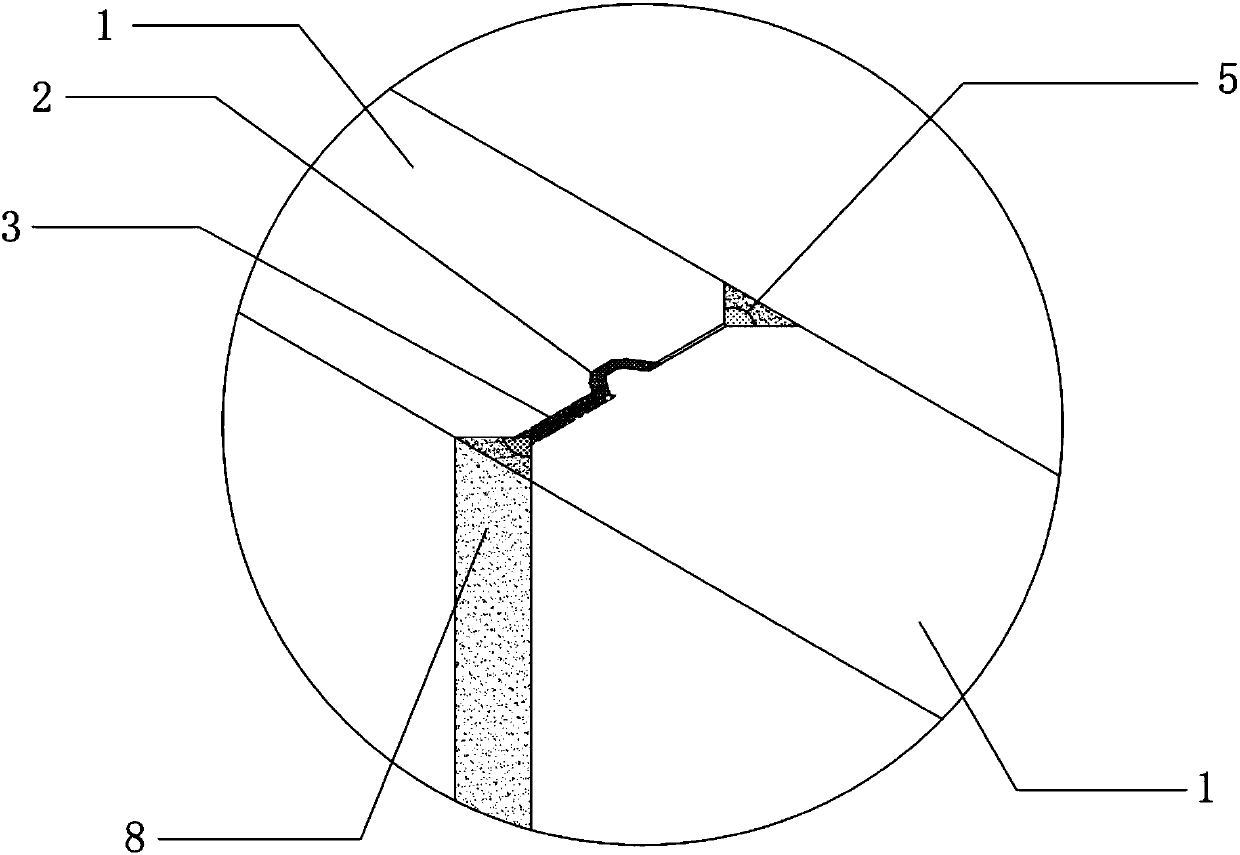

[0069] See attached image 3 , this embodiment is basically the same as Embodiment 1, the difference is:

[0070] In step (6), the following steps are also included: filling the recesses on both sides of the partition wall with fireproof sealant 5 and then filling with filling material 8 to level the surface of the partition wall. To improve the sound insulation and waterproof performance of the partition wall.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com